- The ganging and nesting process takes time, skill, training, and experience—which means paying higher labor rates for skilled workers for an extended period.

- According to Keypoint Intelligence’s research, 88% of wide format PSPs gang and nest jobs manually. The labor costs associated with doing so are staggering.

- Tilia Labs applies artificial intelligence (AI) programming and uses experientially learned pattern recognition to identify efficient potential nesting approaches across images and jobs.

By Greg Cholmondeley

Introduction

The three biggest profit killers in wide format printing are:

- Waste: Print service providers (PSPs) don’t worry about the white space that is left on narrow format pages because entire sheets are delivered to customers, but wide format printing is different. PSPs will typically trim these prints to create customer deliverables, so any unused white space becomes wasted substrate with wide format jobs. That waste can be expensive!

- Time: Media feeds through roll-fed wide format printers occur at a fixed pace regardless of the amount of printing. Thus, every square inch of inter-image whitespace reduces throughput. Since wide format printers don’t print at hundreds of pages per minute like their narrow format counterparts, this wasted time can make it more difficult to achieve deadlines while also impacting shop throughput.

- Labor: Every successful wide format PSP gangs jobs and nests rectangular and irregularly shaped images to reduce waste. However, there can be millions of ways to gang and nest the current job mix at any given time. The sheer number of possibilities makes manually performing this task more of an art than a science. The process takes time, skill, training, and experience—which means paying higher labor rates for skilled workers for an extended period. Furthermore, the time that staff members spend performing these tasks is time they could have spent handling more profitable work.

Minimizing these three issues is key to running a successful printing operation.

Automated Nesting and Ganging Can Boost Profits

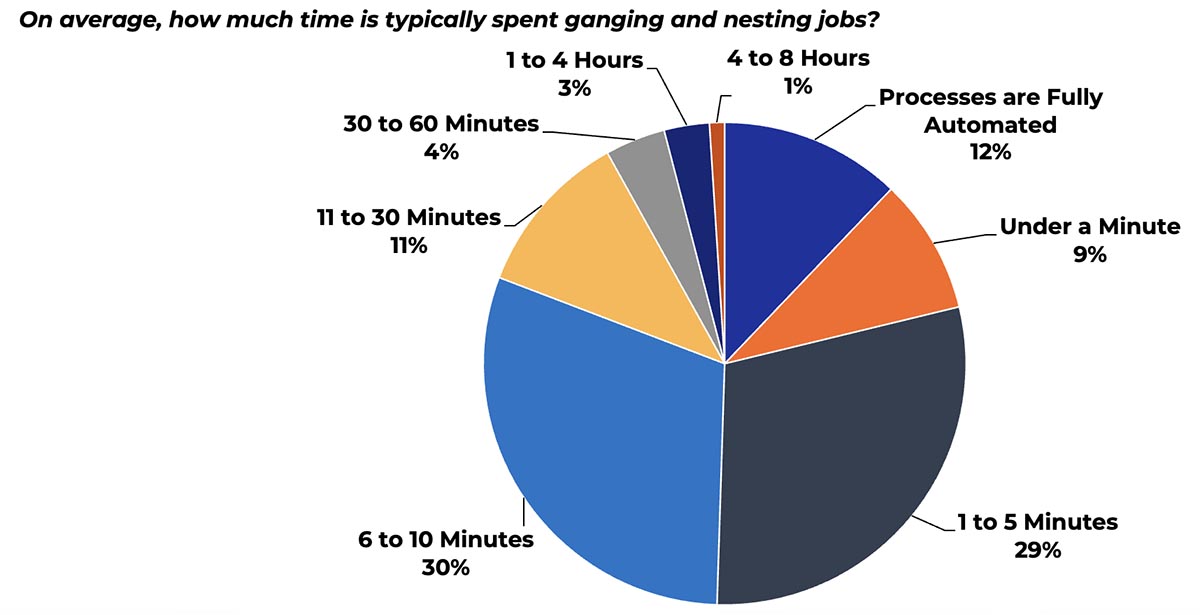

According to Keypoint Intelligence’s research, 88% of wide format PSPs gang and nest jobs manually. The labor costs associated with doing so are staggering, with 59% of respondents reporting that this task averages 1 to 10 minutes per job. Another 19% claim that the process takes even longer.

Figure 1. Time Spent Ganging and Nesting Jobs

N = 190 Respondents

Source: Wide Format Application Survey; Keypoint Intelligence 2019

Determining when whitespace utilization is “good enough” can be difficult—and “good enough” is rarely the best option. Wide format PSPs who manually gang and nest jobs must constantly balance the tradeoff between labor and waste. Every minute spent planning and impositioning print jobs reduces profitability, yet every square inch of unused substrate also costs money. Automating job ganging and nesting can significantly reduce labor and waste.

Of course, it’s not surprising that so many wide format PSPs still manually perform these functions—traditional computer-driven ganging and nesting programs, particularly those involving irregularly shaped images, are usually expensive and slow. Brute force methods to solve these problems with millions of possible combinations take considerable time, even for computers. Most of these programs start with predefined templates, try every possible combination, and give up after a predetermined number of attempts or once coverage is achieved. In this case, human experience, perception, and intuition can often be more effective at solving problems than computers.

Maximizing Optimization with AI

Tilia Labs applies artificial intelligence (AI) programming to resolve these profit-killing waste and labor problems. The system uses experientially learned pattern recognition to identify efficient potential nesting approaches across images and jobs. Thus, the solution combines the power of computers to inspect millions of combinations while also borrowing the human ability of starting with the most likely candidates. Tilia Labs’ software starts with learned solution approaches, but it continues to recognize and learn new patterns for any mix of jobs and job elements.

This intelligent planning and impositioning software helps wide format PSPs optimize production by better managing the influx of smaller jobs while maximizing print efficiency. Tilia Labs’ range of planning and intelligent imposition solutions enables wide format PSPs to get the most out of their equipment, substrates, and labor costs.

The software’s Imposition AI understands the mix of jobs, looks across all available printing methods, and calculates thousands of potential production layouts in seconds rather than hours. Wide format printers typically measure waste in terms of non-productive employee time, overprinting, and rejected work. Although measuring the amount of wasted white space on media from inefficient impositioning is more difficult, these figures can become substantial with escalating substrate costs. According to Tilia Labs, customers realize an average of 15% less material use when using its solutions versus traditional approaches. That can result in significant savings across jobs and over time.

The Bottom Line

Intelligent planning and impositioning are critical for eliminating the three wide-format profit killers and reaching maximum velocity in your wide format printing operations. While there will always be a place for experts who are skilled in nesting and ganging, maximizing their time with tasks better suited to human intervention and using AI solutions for simpler issues can improve efficiency. It also offers the added benefit of keeping employees engaged with challenging tasks rather than pointless busywork.

There are plenty of solutions on the market that enable businesses to achieve higher ROI and profits. It’s a good idea to review all of the available options and make sure that the features and functionality best match your needs and help minimize labor, time, and media waste.

Greg Cholmondeley is a recognized expert on workflow automation, strategic planning, software solutions, and the printing industry. Before joining Keypoint Intelligence, he was President of PRINTelligence Consulting, where he analyzed and assessed production enhancement software solutions for vendor development and consumer understanding. He is a frequent speaker and panelist at industry events as well as a published author.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free