Recently I shared my visit to Mercury Press and their interesting mix of production inkjet technologies. At that time, I had a chance to look at the first placement of the Landa S10P B1 perfecting press. I was duly impressed at the quality, and more importantly at the genuine appreciation of Mercury’s experience, after only a few months of production. Last week I had an opportunity to meet and hear from the owners of the seven currently installed Landa presses and the future owners of five additional presses that will be installed during the remainder of the year, as well as quite a few interested prospects from around the world.

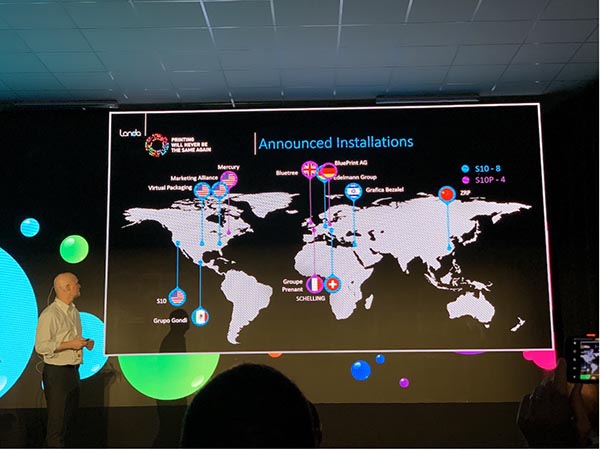

As you can see from the illustrated map above, the installations and pending installations are a mix of the two currently shipping sheetfed B1 presses, the S10 and the S10P. After two drupas’ worth of introduction, the Landa presses are shipping as fast as Landa is willing to ship them. At this point, they are on track to ship close to 15 by the end of the year. Landa has been metering the shipments of presses to the field in order to ensure that the presses and field support are ready. In speaking with those owners who have the press, even though some of them have been waiting eight or more years for their press, they are glad that Landa has taken their time to release them. Although, when asked if they had any regrets, at least three of them said they wished they had initially purchased two presses instead of one!

Taking Full Control

As I have mentioned before, one of the holdups has been the development of the AQM (Automated Quality Management) software. Since the Landa presses rely heavily on upgradable software control (think Tesla), AQM is a critical component of the design. Initially Landa outsourced the development of AQM in an effort to focus on the press design, control, and manufacturing. Although it was decided that in order to get a total 360º control, Landa would bring AQM development in house, and “very shortly” they will release the internally developed version of AQM. It is already running very successfully in R&D and at a couple of beta sites.

This move is significant in that it will allow them to streamline their software design and control processes, thereby allowing them to address any issues or feature development much more quickly. In speaking with all of the current owners about the state of AQM, they have all been very forthcoming about the evolution of the AQM software, their positive relationship with Landa, and the responsiveness they show when any issues are raised.

© Landa

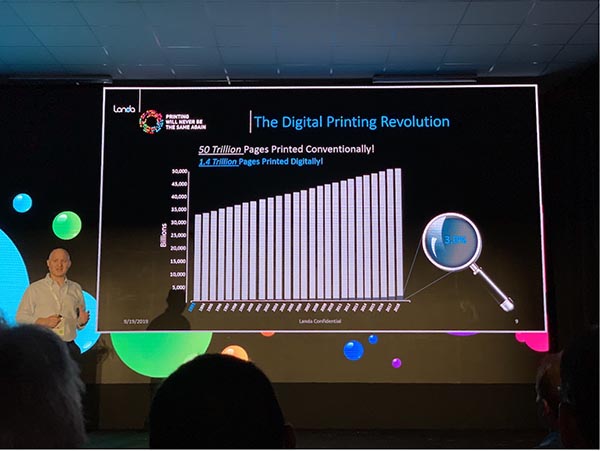

Quicker AQM development should also allow the Landa presses to move beyond their current 6,500 sheets per hour (sph) production speed to their projected 13,000 sph speed or faster. While all of the current press owners are very happy with the 6,500 sph speed, they all agree that the faster speed should allow them to migrate more work from their analog offset presses to the Landa. This is ultimately the promise and plan of Landa as well. Considering only about 3% of the total global print production in the market is digital, including all digital technologies, capturing a larger share will depend on production speeds and cost. And while there are many new production inkjet presses coming to market, currently the Landa presses are the only sheetfed presses that hold that promise.

The Web Press

The third press, the W10 webfed press, supports a web width of 41.3 inches and will be going to beta later this year, exhibited at drupa 2020, and shipping next year. Initially it will support 328 ft./min. and should reach 656 ft./min. in the longer term. During my visit to the factories in Israel on this trip, I saw three W10 presses on the floor, all in different levels of completion. For those who have been following the Landa development, Landa has been working with established market leaders for their transports, while Landa has developed all of the imaging and control. In the case of the sheetfed presses, they partnered with Komori. In the case of the webfed presses they have partnered with Omet, a leader in flexographic transports.

Once available, the W10 will be available in both a simplex and duplex model, with optional precoat and white to target the flexible packaging market currently supported by the slower toner-based devices, and there seems to be quite a lot of interest from that market constituency. I would also expect to see some embellishment functionality (perhaps Nano Metallography?) on display at drupa 2020 for other packaging and commercial requirements.

Landa W10

Building a Community

One of the more interesting parts of this event was seeing and speaking with the current and future owners of Landa presses both locally on stage and virtually through Skype. This was the first time that most of them had even met each other and had a chance to share experiences. Whether planned or not, it turns out that this was the first meeting of the Landa Users Group, and it was exciting for all. They also had a chance to meet and welcome the newest member, Quantum Group CEO Cheryl Kahanec, who is expecting their press mid 2020. Although, after what she considered an eight-year courtship, she was ready to load it into the plane and take it home with her.

Interestingly almost all of them had made the determination that they wanted a Landa press after their first introduction to it at drupa in 2012 or 2016, something I found in common with many of the other potential Landa customers at the event.

What is the future of the Landa Users Group? One of the interesting propositions was that they could have an opportunity to actually create a distributed global network that is naturally supported by the tight software control of the presses. While this is not a new concept, it will be interesting to see if and where that prospect goes.

If we look at the value to both the customers and press manufacturers of existing user groups like those of Canon, EFI, Ricoh, KM and others, this is an important step for Landa and their customer base.

The Tides Are Changing

It was very evident that this was “the” coming out party for Landa. Both the customers, who are very satisfied, and Landa, who is ramping up for a global presence and high demand, are ready to participate in the Inkjet Revolution. The tides are changing…

More to Come…

I would like to address your interests and concerns in future articles as it relates to the manufacturing of Print, Packaging and Labels, and how, if at all, it drives future workflows including “Industry 4.0.” If you have any interesting examples of hybrid and bespoke manufacturing, I am very anxious to hear about them. Please feel free to contact me at [email protected] with any questions, suggestions or examples of interesting applications.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free