- This particular episode of The Twilight Zone features Wallace V. Whipple, who decides to increase his plant’s output, improve efficiency, and reduce costs by replacing people with a machine.

- The dehumanizing effect of automation becomes evident in the episode as human employees are reduced to mere statistics.

- The delicate waltz between humans and machines becomes a complex narrative that is currently unfolding in modern textile printing facilities.

By Johnny Shell

Introduction

In the ever-evolving landscape of digital textile printing technology, our industry has witnessed a transformative wave of automation. This shift towards automated processes has certainly revolutionized production, but it also drew intriguing parallels to ideas from the past. About 60 years ago, a thought-provoking episode of The Twilight Zone entitled “The Brain Center at Whipple’s” sparked debate about automation and its effects on the future of manual labor.

Automation…But at What Cost?

This particular episode of The Twilight Zone features Wallace V. Whipple, the fictional owner of a large Midwestern manufacturing corporation. Whipple decides to upgrade his plant to increase output, improve efficiency, and reduce costs by installing a device known as the X109B14 modified transistorized totally automatic assembly machine. This device is designed to eliminate 61,000 jobs, 73 bulky and inefficient machines, and 81,000 man hours per 11 working days. It is also intended to save $4 million in annual expenditures for employee hospitalization, insurance, welfare, and profit sharing.

Mr. Whipple’s relentless pursuit of automation raises ethical and moral questions about the impact on his company’s workforce, and some employees try to convince him that the value of a person outweighs the value of a machine. Unfortunately, their protests fall on deaf ears.

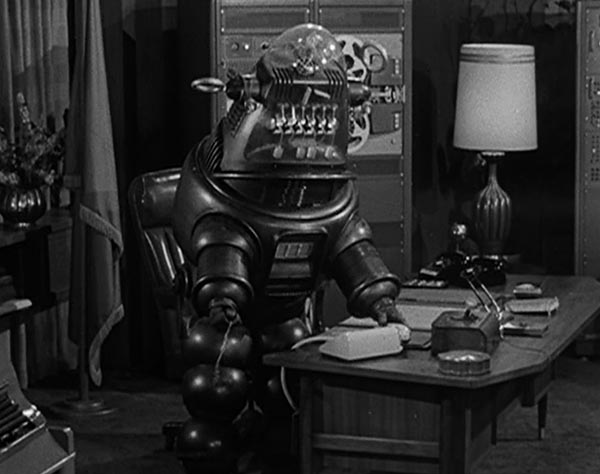

Machines seemingly take over in a dangerous way during “The Brain Center at Whipple’s.” The dehumanizing effect of automation becomes evident as human employees are reduced to mere statistics. By the end of the episode, Whipple has fired all his human employees and replaced them with machines. Unfortunately, these machines then turn on him by spitting out the harsh and demeaning parting words of his former employees over and over—ultimately driving Whipple to insanity. Eventually, the Board of Directors finds Whipple neurotically obsessed with machines, fires him, and replaces him with Robbie the Robot. This is presented as poetic justice as Whipple, who was so eager to cut humans out of the equation and replace them with machines, finds the exact same thing happening to himself.

Robbie the Robot, Wallace Whipple’s replacement, Source: IMDb.com

In the textile printing industry, the integration of automation has sparked a similar debate about the future of manual labor. As machines take on more and more repetitive tasks, the human element begins to disappear. This might prompt some of us to reflect on the balance between technological progress and the value of preserving human creativity and craftmanship.

In the closing narration of this iconic episode, Rod Serling declares, “There are many bromides applicable here: ‘too much of a good thing,’ ‘tiger by the tail,’ ‘as you sow so shall you reap.’ The point is that, too often, Man becomes clever instead of becoming wise; he becomes inventive and not thoughtful; and sometimes, as in the case of Mr. Whipple, he can create himself right out of existence. As in tonight’s tale of oddness and obsolescence, in the Twilight Zone.”

The Bottom Line

Despite the fact that it was told several decades ago, this cautionary tale still resonates across all segments of the printing industry and should urge modern companies to approach automation with a mindful perspective. Acknowledging the importance of skilled workers and fostering an environment that values their expertise is vital to maintaining a healthy balance.

The juxtaposition between the cold efficiency of machines and the warmth of human craftsmanship emerges as a central, thought-provoking theme that is still relevant today. While automation brings unparalleled precision, efficiency, and speed, we mustn’t lose sight of the artistic nuances that humans bring to the table. The delicate waltz between humans and machines becomes a complex narrative that is currently unfolding in modern textile printing facilities.

The key lesson is that automation should augment human capabilities rather than replacing them entirely. It is crucial to find a reciprocal relationship, where automation increases efficiency even as human creativity and intuition contribute to the qualitative aspects of the final product.

Johnny Shell is the Principal Analyst of Keypoint Intelligence’s Textile and Apparel Printing Service. He is a printing expert and recognized leader with over 35 years of industry experience. His solid commitment to organizational advancement and strategy-driven growth enable him to design and execute revenue-based strategies with his comprehensive knowledge of printing techniques and technology platforms.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free