Source: Kyocera and My Father’s World

In the world of homeschooling and microschooling, educational publishers need efficient print solutions.

Just ask My Father’s World in Rolla, Mo., a content publisher who faced the challenge of providing high-quality print solutions for a variety of materials, from teacher’s manuals to student textbooks and supplementary resources, delivering content cost-effectively as well as meeting diverse customer needs. However, the publisher was recently able exceed the demands of their customers by using a combination of inkjet and digital printing technology.

Source: Kyocera and My Father’s World

Printing at My Father’s World

Source: Kyocera and My Father’s World

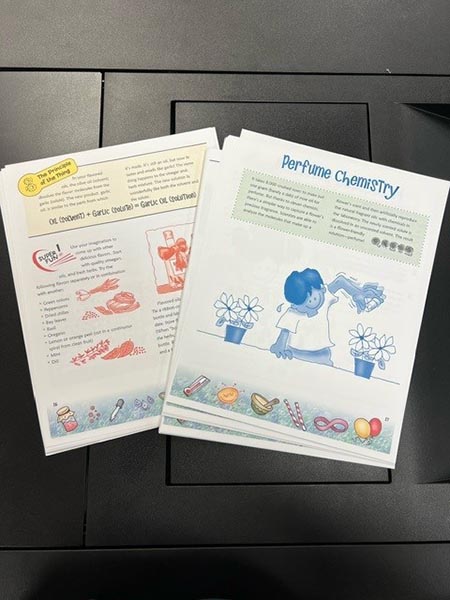

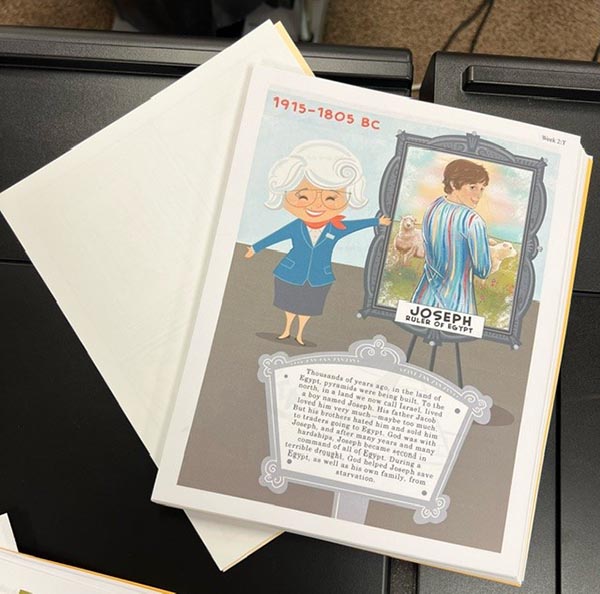

My Father’s World is an in-plant print shop responsible for producing top-quality Christian curriculum material focused on preschool to 12th grade. That content is used by those who homeschool, microschools, and larger educational institutions. Each package is a mix of text and graphic content used by those schooling single learners and entire families. Each grade has teacher’s manuals and curriculum packets that engage with content supported by artwork that relies on color. Like any in-plant, they look for printing technologies that allow them to balance costs and quality.

Jon Dalton, Production Specialist at My Father’s World, was looking for the next solution that could support their need to reduce costs without cutting back on the rich quality they support. Their toner solutions produced excellent output but at a challenging cost. They acquired inkjet to have the right technology to deliver color pages at the lowest cost.

As Dalton puts it, “The reason we purchased it is that it has a much lower cost all around. Not only in the materials like the ink but also in the cost of the operation. It uses a lot less electricity.” Their previous generation of toner devices required a lot of heat to adhere the rich color to the paper, and that energy meant a lot of power to run the press.

Transforming their production with the Kyocera TASKalfa Pro 15000c meant converting to inkjet. The impact on overall running costs was immediate. Not only does it cost less to power the machine, but ink costs less, too. Dalton says it was a significant cost reduction. Going to ink from toner saw costs reduced by as much as 75%. “It is dramatically lower,” he says. “We have a product that we were just printing the other day on our toner-based machine. It was a little over $4 in clicks. Using the ink on the Kyocera, we’re a little over 40 cents.”

Dalton is also excited that he is getting exceptional quality in addition to the significant savings. My Father’s World has moved more of its work to the TASKalfa Pro 15000c than originally planned because of the quality and ease of use. They run with a small group of staff, so the ability to work with a single operator means it can run throughout the day, keeping the jobs moving. “It's an excellent printer, and the savings are incredible,” he says.

The Power of Inkjet for Content Publishing

Educational content publishing comes with a special set of requirements, including a higher degree of color, even as there is more pressure on the cost model. The Kyocera TASKalfa Pro 15000c has become the leading upgrade for these publishers because it is designed for in-plants of all sizes that need the capacity of a high-volume printer but the versatility to print on a variety of substrates in full color at a reasonable cost. In-plants require operator-friendly presses that start up quickly, print reliably, and have low maintenance requirements. The TASKalfa Pro 15000c meets those demands.

Because the TASKalfa Pro 15000c is designed to consume less electricity than its competitors, it is also eco-friendly and sustainable, which is more important than ever before. Engineered for efficiency, it has a limited number of moving parts, thus reducing downtime for maintenance.

These features make the Kyocera TASKalfa Pro 15000c a strong choice for educational content publishers looking to enhance their color printing capabilities while maintaining efficiency and sustainability.

Discussion

By Chuck Werninger on Mar 04, 2024

Great article and very timely, Pat. These presses are high-value and deliver a lot of productivity in a small and cost-effective package so I think they will do very well in the education and in-plant space. If you lead one of these shops, I'd recommend you take a close look before making your next investment.

By Pat McGrew on Mar 04, 2024

Jon Dalton tells a great story! He did his homework and found the solution that helps make them mega-productive!

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free