Yesterday, David Zwang covered some of the label and packaging highlights from last week’s PRINTING United Expo in Atlanta. And, yes, as Dave pointed out, choice of footwear was a crucial one, lest one spend the following week consulting with a world-class team of podiatrists.

Anyway, in this article, I want to round up some of the major press announcements made at the show—most of which surrounded wide format and textiles—as well as some of the other wide-format technologies on display.

Press Events

I always prefer it when exhibitors have press conferences in their booths, and not just because of the often-vast distance from the show floor to the press conference room, but because it also puts the focus on the equipment rather than on the “death by PowerPoint” one sometimes gets at these events.

Case in point: Durst and Vanguard, whose press conference was a booth tour. In 2018, Durst launched its P5 platform, which has grown to become a vast ecosystem including printers, inks, and software, as well as training, consulting, and other services. The most recent addition to this line is the P5 350 HSR, an 11.5-ft. roll-to-roll machine that can print up to 7,212 sq. ft./hr., which made its North American debut in Atlanta. It joins the P5 350 HS, an 11.5-ft. hybrid printer that can print up to 7,620 sq. ft./hr. Durst is heavily involved in textile printing for soft signage, lightbox graphics, etc., and had on hand the P5 TEX iSUB dye-sub direct-to-fabric printer (it can also work with transfer papers). It features Inline Sublimation (iSUB), enabling one-step printing/fixation process, precluding an extra calendering step. Showing the full range of their offerings, they were also showing a label printer, with a name that seems a throwback to the pre-P5 Greek letter naming convention: the Tau 330 RSC, which prints up to 262 ft./min. Durst’s tagline this year was “360° Production Excellence,” which also comprised the company’s Durst Software & Solutions: ERP/MIS software designed to streamline and automate “every aspect of the print business”; a Web-to-Print solution; Prepress & Production software for automating prepress and production; and Analytic software to allow examination of production data to increase equipment efficiency and glean other important metrics.

Durst P5 350 HSR

In 2021, Durst had acquired a majority stake in Vanguard Digital Printing Systems, known for its high-end flatbed and hybrid UV wide-format printers. In Atlanta, they were showing its next-generation VK3220T-HS flatbed printer, making its North American debut—and showing off Vanguard’s new printer design. It is a 10.5 x 6.5-ft. UV flatbed that can print up to 3,875 sq. ft./hr. It features a larger bed size than previous Vanguard units, up to three rows of printheads for high productivity, and an electromagnetic carriage drive system for speed and precise drop placement. It is said to print on nearly any substrate up to 4-in. thick.

Vanguard VK3220T-HS

The Atlanta show was a coming-out party for ECO3, formerly known as Agfa Offset Solutions, which made its official North American debut at PRINTING United. The company provides equipment, software, plates, and film designed for highly automated and eco-friendly prepress and production for commercial printing and packaging workflows. On the software side, the latest version (v13) of the now-20-year-old Apogee and newer Amfortis (v2) workflow, the latter designed to be an “integrated command center” to streamline all prepress tasks for packaging workflows. (Also on the packaging side, at LabelExpo last month, ECO3 launched its Magis imaging equipment and flexo plate solution.) A new screening technology (SPIR@L) is also designed not only to improve print quality but also save ink—and costs. ECO3 was also demonstrating its process-free Eclipse and chemistry-free Adamas printing plates, the latter of which can reduce waste by up to 80%. ECO3 was also showing its thermal, zero-process Avatar T-ZP plates for newspapers and nonheatset web, which are compatible with all newspaper thermal platesetters. Although not on display, ECO3 also offers a robotic plate-loading system for their Avalon VLF platesetters. The robot can be custom-built to a printer’s specific requirements and can load up to 60 printing plates an hour.

ECO3’s flexo workflow for packaging

EFI brought many members of its wide-format and textile printer family, including the 3.5-m EFI VUTEk Q3r roll-to-roll UV printer, the 3.4-m EFI VUTEk FabriVU 340i+ dye-sub printer featuring inline sublimation, and 3.2-m EFI VUTEk h5 hybrid roll/flatbed UV printer. Like a number of vendors who have very large machines, EFI couldn’t fit its Nozomi machines into its booth, so featured videos and print samples. (You know, if wide-format printer manufacturers could figure out how to get printers to print vertically, they could save a whole lot of space. Sure, it would probably defy the laws of physics, but it might be worth a shot…)

In yesterday’s feature, David Zwang discussed Fujifilm’s major announcement—the B2 Revoria GC12500 toner press—but, as befits the exhibitor with the biggest booth, it was stuffed with representative models from all the Graphic Communication Division’s lines. In the wide-format space, the company’s long-standing Acuity line of UV inkjet presses, including the 5m Acuity Ultra R2 toll-to-roll press and the 3.3m Acuity Ultra Hybrid LED printer. They also had a scale model (the actual press is over 30m long!) of the forthcoming HS6000 that had been previewed last spring at FESPA Munich, a single-pass behemoth developed in collaboration with Barberan. While most single-pass machines have been thus far targeted toward the corrugated market, this is one of the first to be developed primarily with high-end sign and display graphics providers in mind. It is said to be able to run up to 6,000 sq. m/hr. It will be available sometime in early 2024. We’ll be keeping an eye on this one.

Kornit Digital’s press conference identified the latest trends in textile and apparel production, one of the most important being that the old model of textile production—mass produce, then distribute, then discard excess unsold inventory—has become woefully out of fashion. On-demand textile production is becoming the norm, which is having the twin effects of reshoring (or at least nearshoring) production and bringing brands closer to the consumers. At the same time, retailers like Life is Good are starting to bring digital textile printing in-house, the goal being, rather than mass production, to “print to the shelf.” It is also a more sustainable model, with the potential to dramatically reduce waste, as Cary Sherburne and Debbie McKeegan have written about often. Kornit is dedicated to pigment-based digital textile printing, which is a more sustainable production solution, as it eliminates the need for water and pre- and post-treatments. At ITMA in Milan, Kornit introduced its Apollo platform designed for high-throughput, automated digital production. Currently in beta, it is capable of up to 400 garments/impressions per hour, and a partnership with Adobe adds robust color management to Apollo. The press event also included a customer panel featuring Augusta Sportswear and Mad Engine, apparel producers who confirmed many of the trends outlined earlier in the presentation.

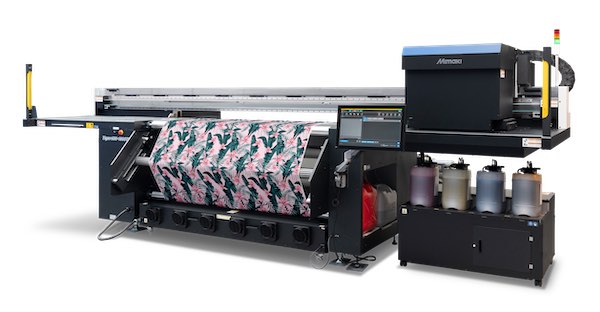

Mimaki had a host of new products equally divided between textiles and apparel and signage and display graphics. On the textiles side, the Tiger600-1800TS High-Speed Sublimation Printer debuted at ITMA in Milan, and made its North American debut in Atlanta. It’s a roll-to-roll sublimation transfer inkjet textile printer that can print up to 5,920 sq. ft./hr. and is designed for long production runs. Mimaki is big into direct-to-film and hot on the heels of the TxF150-75, which debuted last April at the ISA Sign Expo, comes the introduction of the TxF300-75 Direct-to-Film Printer, which boasts a 300% increase in productivity compared to its predecessor. The company was also introducing TRAPIS, a one-step waterless textile pigment transfer printing system that is compatible with a wide range of natural, synthetic, and blended fiber textiles. Like other pigment-based solutions, it eliminates the need for water and pre- or post-treatments, making it a more sustainable solution. Speaking of sustainability—and this sounds very cool—Mimaki launched its Neochromato Process, a technology that extracts dyes from printed polyester textiles so that they can be reused—up to 20 times. Comprising a heat press and a proprietary fluid to remove dyes from the fabric, it addresses end-of-life issues by diverting printed textiles from landfills. It’s a safe bet that either I or our textiles doyenne Cary Sherburne will be following up on this.

On the sign and display side, Mimaki announced the UCJV330 series, a UV-LED roll-to-roll inkjet printer boasting improved productivity and image quality for sign graphics printing applications. A UV printer, it was designed to help print providers move away from printing on PVC, which is starting to be phased out either by end users and/or local ordinances. As a result, the new UCJV330 units print on a variety of substrates designed for indoor and outdoor applications, including translucent and transparent films as well as PET, polyurethane and other resin films, cloth, and paper. Finally, the entry-level UJV100-160Plus UV-LED Roll-based Printer is a 64-in. unit that features white and clear ink options and boasts an “ink saving function” to reduce ink consumption.

Tiger600-1800TS High-Speed Sublimation Printer

Around the Floor

There is only so much one person can cover at a show this big, but here are some of the other products and vendors I came across. I will no doubt be giving some folks short shrift without this being a 25,000-word article, but I hope to follow up with some deeper dives in future feature articles.

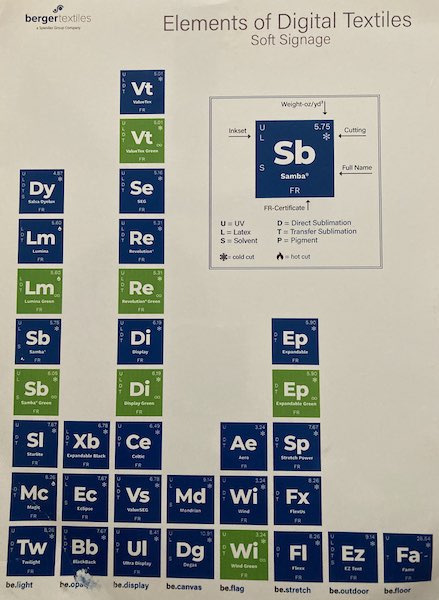

Cary Sherburne usually covers textiles, but soft signage is technically my beat as well, and Berger Textiles—which was founded in 1849 in Krefeld, Germany, as Schüssler & Co—today offers a full portfolio of substrates for soft signage, décor, and other applications. At PRINTING United, they launched two new substrates: Shift, an “odor-control textile” designed to absorb and neutralize things like kitchen odors, animal/pet smells, and tobacco smoke. It can even capture and neutralize formaldehyde, if that’s something you need to worry about. It’s a 250 gsm polyester material that can be used in display frame systems, banners, and interior graphics, and can be used as is or be printed direct or dye sublimation printing. Berger also launched Moon, a gray-back polyester designed for high opacity. It’s a 330 gsm material compatible with direct and transfer-based dye-sub printing and suitable for a variety of display applications, such as frame systems, lightboxes, silicone edge graphics, wall décor, pop-up banners, and more. Most of Berger’s portfolio are being converted to more sustainable materials. I should also point out that Berger also has one of the most elegant product identifiers I have ever seen, based on the Periodic Table of Elements that identifies its weight, ink/technology compatibility, and other specs.

Berger Textiles’ Elements of Digital Textiles is brilliant.

Epson was showing what has become one of the most comprehensive wide-format portfolios, with units that include solvent, dye-sublimation, UV, and resin (i.e., latex). They also have a hybrid direct-to-garment/direct-to-film and, while they have not officially launched it yet, they were previewing a UV “bench top” printer for specialty printing. More to come on that.

HP was showing its latest Latex line, the Latex 630 Series, an “entry-level” line aimed at small and midsize print service providers. HP had announced this new series a few weeks ago (see my write-up here) and it comes in four “flavors”: the base HP Latex 630, HP Latex 630 W (offering the ability to use white ink), HP Latex 630 Print & Cut Plus (offering, as you would expect, print-and-cut functionality), and HP Latex 630 W Print & Cut Plus (offering white ink and print-and-cut capabilities).

HP Latex 630 Series

LogoJET got its start in the direct-to-object (aka specialty printing) market with a unit originally designed to print on golf balls, and they have expanded over the past 25 years—even adding an edible ink printer for printing on cookies and other comestibles. This year’s PRINTING United saw the company’s first foray into full-fledged wide-format printing with the launch of its Strata Series, comprising two UV flatbed models: the 3.2 x 5.9-ft. Luna and the 4.9 x 8.2-ft. Terra.

LogoJET Terra

Onyx announced ONYX Align, print business management software. Cloud- and subscription-based, ONYX Align product provides end-to-end order management, customizable production management controls, and predictive estimation tools for fast quoting and reporting for any size print business.

Roland also boasts one of the most comprehensive wide-format portfolios, and were showing off their full line of eco-solvent, dye-sub, resin (i.e., latex), and UV models. My booth visit also included a side-trip to the booth of a recent Roland acquisition—Lithuania-based Dimense. Back in August, Roland had announced that it had purchased a 50.1% interest in the company, which has a unique digital printing embossing solution for creating wallpaper and other highly textured display graphics. The system is a combination of rollfed printer (the Dimensor S), aqueous latex-based inks, a proprietary “structural” ink, and a range of layered substrates. The way it works is that when the substrate is exposed to heat in the printer, the top later “foams,” while the areas covered by the structural ink prevent foaming. When the substrate cures, you end up with a highly textured print. There is also version of the machine that adds glitter. This is one of the coolest technologies I have seen at a show in a long time. Look for a deeper dive on this technology in a future article.

Dimense’s Dimensor S with glitter printing option

At the End of the Day

I agree with David’s assessment that the future of in-person trade events is a rosy one. Having experienced a year of virtual shows back in 2020, they are no replacement for the ability to see equipment in action, meet up with old friends and colleagues, and meet new people coming into the industry.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free