- COVID-19 is accelerating Industry 4.0 adoption, leading companies across industries into a more mature state of IoT technology and workflow.

- Although businesses have had reason to embrace digital workflows in the past, COVID-19 has provided another strong incentive to move toward a smart factory, complete with smart manufacturing or smart printing processes.

- While conventional wisdom says that a dedicated office space is required to maximize productivity, this theory is being put to the ultimate test as we speak.

By Colin McMahon

Introduction

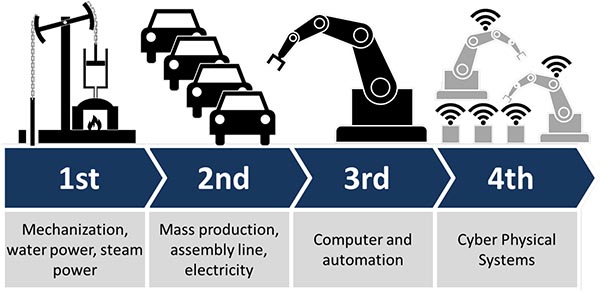

Over the past decade, much has been made of the advent of Industry 4.0. While experts argue over what stage of technology we are in (some consider this period to be the fifth revolution, centered upon information and telecommunications technology), the majority agree that Industry 4.0 began with the arrival of the Internet and mainstream digital technology, specifically Internet of Things (IoT) devices.

That said, few would dispute that we’re in a period of profound change right now. COVID-19 is causing radical shifts in workflow across the globe as millions practice social distancing and/or comply with self-quarantine recommendations. The pandemic’s dramatic appearance has accelerated numerous trends while slowing others. So, with all of this disruption, could it be said that COVID-19 has caused a premature change in industry operation? Yes and no. There is no doubt that COVID-19 is a transformative force, but it is not bringing us into Industry 5.0. It is merely accelerating Industry 4.0 adoption, leading companies across industries into a more mature state of IoT technology and workflow.

A Truer Industry 4.0

Experts believe that there are four central concepts to Industry 4.0. These include smart manufacturing, the smart factory, dark factories (also called lights-out manufacturing), and industrial Internet of Things (IIoT) technology. All four of these reflect back to a greater trend—automation. Much of Industry 4.0 involves using improved data collection (made possible by IoT devices) to streamline workflow and manufacturing processes.

The Four Major Industrial Stages

For those unfamiliar with dark factories, these reflect the pinnacle of automation. Lights-out manufacturing refers to a fully automated work environment. Whereas people and machines work alongside one another in a smart factory, dark factories do not need a single person present on the premises.

This concept has taken on immediate value as the COVID-19 pandemic takes hold. The idea of a fully functional factory floor that needs no permanent human staff means uninterrupted production output. Nevertheless, many organizations are unable or unwilling to commit to this level of automation. Smart factories still dramatically reduce the number of workers needed as most simple tasks are automated.

Even small manufacturing sites tend to have more staff than the average retail environment. Adopting more smart manufacturing processes reduces the dependency on human workers, meaning that factories can reduce the size of a shift without downsizing production. It also means guaranteeing the workers who are present a lower chance of exposure. People must be close together for the COVID-19 virus to transmit, and maintaining a physical distance of at least six feet dramatically reduces the chance of infection.

Although businesses have had reason to embrace digital workflows in the past, COVID-19 has provided another strong incentive to move toward a smart factory, complete with smart manufacturing or smart printing processes. Keypoint Intelligence would not be surprised to find that the organizations least impacted by the COVID-19 pandemic were the ones with the best automation practices and digital workflow empowerments already in place.

Industry 4.0 Applied to the Office

In many ways, the average office space is no different than a typical industrial factory. Both involve on-site collaboration between employees to create a specialized product to fulfill a certain need. In years past, it could be argued that offices were doing a stronger job of adopting digital workflows than factories, if only because more of their work could be easily digitized. Even so, many businesses have clung to the office mentality—meaning a centralized, physical space where employees gather. Data gathered by JLL shows that this is primarily true for the tech sector, which leases almost 10 million more offices in 2019 than the runner-up, insurance & finance.

This means that a portion of these companies’ revenues are tied up in leasing costs, with some areas costing considerably more than others. Organizations pay these bills for a variety of reasons, including reputation, convenience, or even tradition. Some firms have a central office location simply because things have always been that way.

Now, this is likely to change. While conventional wisdom says that a dedicated office space is required to maximize productivity, this theory is being put to the ultimate test as we speak. The majority of offices across the US and elsewhere are already fully remote or are in the process of shifting to fully remote workflows. These companies have no choice now but to test their performance without the support of a traditional office space.

Should these organizations function at peak productivity (or close to it), the demand for office space may see a significant drop. This could mark a true shift in global workflow—the end of a tradition and a full embrace of the potential of digital workflows.

Other COVID-19 Impacts

Although some print service providers may need to preserve their physical space, they must be aware that nearly every industry impacts their business. COVID-19 has hit the restaurant industry (which is never stable, even in times of economic prosperity) and the movie theater industry particularly hard. AMC, one of the largest cinema chains in North America, has already reported that it may not survive the COVID-19 pandemic.

Damage to these industries and others results in a loss of printed products, as theaters and restaurants are the traditional home to numerous types of signage. At the same time, however, new revenue streams may open up as industries shift in reaction to COVID-19. Today’s print providers must be ready to expand their horizons. The landscape has changed, and it will likely change a lot more in the coming year. It is still too early to predict how industries will be altered and which percentage of these shifts will be permanent, but an evolution is occurring.

The Bottom Line

Although the COVID-19 pandemic has not triggered Industry 5.0, it has brought home the reality of Industry 4.0. Digital workflows and automation are no longer goals; they are requirements. IoT devices have offered organizations a path toward preserving revenue streams during this pandemic. The future is here, but only the savviest businesses will bring it to its full potential.

Colin McMahon is a Research Analyst at Keypoint Intelligence – InfoTrends. He primarily supports the Business Development Strategies and Customer Communications services. In this role, he creates and refines much of InfoTrends’ written content, including forecasts, industry analysis, and research/multi-client studies. He also assists with the editing and formatting processes for many types of deliverables.

Discussion

By Michael Burgard on Apr 09, 2020

While comments in WTT seem pretty sparse, i felt a need to comment. Our experience and that of our customers is showing that remote working is WAY less productive for many reasons

1) Watching children

2) Coordinating with others for input takes many times longer.

3) Poor technology

4) Home based distractions

5) Lack of supervision and guidance.

It is one thing to believe every worker is self-motivated and self-directed and stays on task; it is another to observe real human behavior.

In addition, dark factories might work for producing thousands of refrigerators a month with minor variations in options. It cannot work for average printers where we do hundreds of jobs a month and very few are the same. Maybe a 500 million dollar printer who can scale a factory floor to 20 basic products but not for the 20,000 average printers in the marketplace.

Finally, the picture of work you describe is not utopian but rather dystopian. Without social interaction and value-based work goals, the world of work will indeed become demeaning and meaningless to an even greater share of the workforce. In the midst of Covid-19, my employees yearn for the social interaction and direction that working in the office provides.

By Eric Vessels on Apr 13, 2020

Depending on the content, we actually have some vibrant conversations in comments. Thanks for adding your voice Michael!

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free