(This article first appeared on Inkjet Insight.)

Back in 2013, I participated in a panel presentation on digital and offset economic crossover points with several industry luminaries with whom I immediately, yet politely, began to argue. Actually, Marco Boer and I were both arguing on what we felt was the side of the angels against a number of traditional “facts” about print economics. It was pretty common at that time to throw out a number, like 5,000 or 4,000, as the break-even number under which it did not make sense to run a job on offset, or conversely above which it did not make sense to run on inkjet (or any digital press.) Sometimes the number was defined in terms of US letter or A4 images and sometimes it was not defined at all. The lack of definition extended to the type of inkjet and offset being compared. These discussions, and oft cited charts, made no reference to characteristics like web, sheet, type of ink, coverage, target media, or number of colors that can influence breakeven calculations.

In contrast, it was very refreshing to be invited by Kodak to lead a panel of experts discussing how the “sweet spot” for particular print processes must consider a range of print-operation specific variables. In the 10 years since the first panel, this discussion has only become more complex. The top speed for inkjet presses has risen along with color and other measures for top quality. At the same time, offset make-ready times have shrunk and great strides have been made in trimming waste from the process. Neither technology is standing still.

My co-presenters for the session “Find your sweet spot: the crossover from offset to inkjet” deal with these variables every day.

- Patrick Murray, President of Japs Olson has an enviable range of equipment, including both web and sheetfed offset and digital presses, to drive what he calls a “total package direct mail producer mailing well over 1 billion pieces per year.” I learned in a previous interview with Pat that, before they acquired their first inkjet press in 2014, Japs Olson had over 100 inkjet printheads deployed on hybridized offset equipment.

- Jennifer Wren is a Color Commercialization Engineer with Kodak, where she balances her time between product development initiatives and being out in the field talking to customers about real-world printing challenges. It’s important to note that Kodak derives roughly one third of the revenue from its digital printing segment that it does from its traditional printing, so they have a foot firmly in each camp.

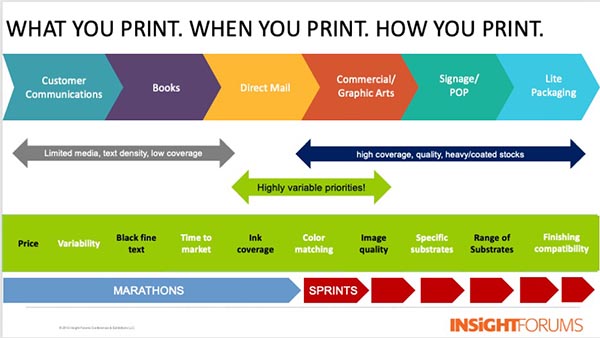

One thing that we all agreed on is that what you are running, and how you are running it, have a huge impact on the economic crossover point for justifying the type of press to invest in as well the day to day running of equipment. In terms of what you run, the type and variety of applications that a press needs to handle has a big impact of the capabilities that will be a priority (see chart below). For companies working in customer communications and monochrome books, fine text legibility and price will be more important than breadth of media, coverage or color quality. At the other end of the spectrum, if you are bridging graphic arts up to light packaging, media range, coverage and image quality become paramount.

Pat said that this chart really captured Japs Olson’s considerations, “We are right in the middle. In the direct mail space there is a lot of personalization and a lot of demand on color and quality, and speed to market is so important. The other piece that is important is finishing capabilities.” He noted that it was important for Japs Olson to be able to use the same finishing equipment with their inkjet equipment that they do with offset to enable flexibility when deciding how to run a job. Pat noted, “When we first purchased our Prosper 6000, it was intended for 4 color variable work only. We wanted to get into that world. We’re finding out that this equipment is really versatile. It’s not for everything but we’ve found a lot more we can run. A lot of static work runs really well on this equipment.”

It’s often the case that when making the business case to purchase a press, there is a specific business case in mind. These days more companies are trying to get into new areas of work, and, in that case, it’s important to look at whether new equipment will be flexible enough to support different requirements. Even if you already know that you want to buy a continuous inkjet press, for instance, your business case needs to consider the specific configuration to support all of the work you want to produce. There might be different drying options or automatic winding or priming or even ink options.

Once you have a press in-house and are trying to optimize volumes across the available equipment, the job characteristics and specific customer priorities can be as important as the volume itself. Jen advised “ There is not a given path that a job has to take to a certain press. It can go in a lot of directions – it could go to offset or to inkjet and there are a lot of different factors to analyze.” If you want to see the details of examples that Jen showed for how the economics change based on number of signatures in a job and other considerations, tune into the webinar replay here.

Of course job volume is an important factor. For our conversation, we talked about volume in terms of marathons and sprints rather than specific run lengths because overall productivity is generally the goal. The same number of jobs and volume running on several different types of media instead of a single media has a significant impact on the efficiency of a continuous inkjet device. It may have no impact on a sheetfed inkjet press with more than one paper feed. Conversely, plate changes are needed every time there is a change to an offset job, so the time for media changes is already “baked in” to the default make-ready penalty on offset jobs. However, that make-ready penalty will be drastically lower for a highly efficient late-model offset press with the latest workflow software than with a 20 year old offset press lacking in automation. It’s important to talk about specific equipment, not just general categories

For many years Japs Olson bought into the generalization that you couldn’t move sheet fed offset volumes to inkjet because the quality would never be acceptable and that roll-fed offset was so fast that inkjet would never be efficient enough. Now they keep an open mind. Pat noted that ink coverage is a big factor in the decision process of where to run a job. “We can run the Prosper 6000 up to 1,000 feet per minute on uncoated stock. And when you look at quality, the thing that keeps blowing our minds is that the lines on quality are getting blurred. Litho is still better, but it’s getting really close.”

Pat said that with the wide variety of digital, offset and hybrid equipment they have running, they are constantly evaluating the sweet spot for their jobs and specific customer priorities, “What everyone who goes through this journey has to do is determine their own sweet spot. For Japs Olson, we produce hundreds of formats. The format and ink coverage and how it’s going to finish are all factors. Our estimating team has been tasked with doing the compare and we continue to find wins. We have moved a lot of static work off of our web offset and onto our Prosper press. The factors there were quantity, quality, ink coverage – all those factors we talked about today need to be taken into consideration. For us, there is a certain ink coverage that is our sweet spot and over that it usually makes more sense to go litho. “

Production cost is usually top of mind for most production operations, but with direct mail, time to market is a big factor that can enable premium pricing. One of the factors that drives down inkjet costs is lower labor cost, which is important in the current market. Pat says, with inkjet “You’re able to train people in half the time that you would on a large litho press. You can have someone productive in a couple of weeks and easily move people around.”

As you can see, there are a lot of factors that go into driving the business case for the type of press you invest in and even more for determining the best place to run an individual job. The “sweet spot” can shift by customer, peak times, or even as you add capacity and try to load balance across equipment. Technology and workflow improvements will continue to impact the cross over points and optimal run economics can also be affected by outside factors like supply chain or labor challenges. Pat summed it up pretty clearly as, “Print and technology is evolving and we have to evolve with it. “ Our industry’s tendency to oversimplify break-even considerations needs to evolve too.

Discussion

By John Zarwan on Aug 01, 2023

Nice piece. There's the straight "economic" calculation -- x cost for plates, y for ink, z for paper, press time, etc. But when is the piece due? How much is being charged for it? And there are (were?) psychological factors. While it's been a while, I knew many printers who would run a job on a sub-optimal press (even offset vs offset) because they couldn't stand to see a press not running. Better to have that small GTO sit idle than our spanking new 6-color, even if the smaller press was more economic.

By Rebecca Shick on Aug 01, 2023

Economics is an important factor for the PSP but there is another consideration from the PSPs customer, especially with books. Book printing on demand is critical for publishers. Their economic considerations include inventory management and cost. Warehouse storage is at a premium so being able to print books within a day or two of ordering gives the pubs the ability to have PSP ship directly to the end user, thereby eliminating storage and warehouse staff costs. That is huge worldwide.

By Elizabeth Gooding on Aug 01, 2023

John - good to hear from you. From an academic perspective there is a straight, if complex, calculation but usually the situation is more bendy than straight - particularly when comparing to inkjet where the type of paper you are running impacts the amount of ink you use (for instance). The point is that every situation needs to be evaluated on its own merits - not based on a rule of thumb.

Rebecca - thanks for your comment as well. Book printing adds a whole raft of additional considerations into the mix. Inventory levels, tax consequences of holding inventory, shipping, the projected sales curve of an individual book. A couple of years ago I was trying to find a couple of publishers to work with to develop inventory models for different types ow publications. Great application for a monte carlo simulation approach.

By John Zarwan on Aug 01, 2023

Exactly Elizabeth. I'm actually surprised that this is still being promoted. It was something that was initially pushed in the 90s (and a little into the early aughts) by the vendors and a few consulting firms with an agenda. In my talks on digital print and offset I referred to the shrinking definition of short run (from an initial 10000 to your 4000 or even less), as offset became more efficient (partially in response to the digital challenge). As you point out, even an economic calculation is complex, each plant (or job) is different. My point is that there are a host of other factors that matter as well. The "economic crossover" point isn't irrelevant, but really shouldn't be the primary determinant.

By Elizabeth Gooding on Aug 01, 2023

Thanks John, you summed it up well. Unfortunately, as with many topics today, some people remain in an echo chamber where they only talk to people who already agree with them and don't look outside the bubble. I'm lucky to have the opportunity to work and consult with people who are out in the field seeing what different companies are actually doing and the variation is eye opening.

By Howie Fenton on Aug 01, 2023

Elizabeth,

Congratulations on your excellent article. I enjoy reading your articles. I wholeheartedly agree with your insights on evaluating break-even points for various print technologies and would also like to add the need to evaluate the risks. It is indeed a complex issue, heavily influenced by the specific application, encompassing all costs and risks. Each application is unique and requires ongoing content reevaluations as offset, digital, and finishing options evolve.

Having spent years working with a textbook printer, I have witnessed the dynamic nature of the industry. Initially operating with two newspaper presses and two sheetfed presses for two shifts daily, the company has gradually transitioned towards inkjet printing. This shift has been prompted by the ever-changing landscape, where digital technologies and finishing options prove advantageous when considering the total cost of operations (TCO) and associated risks.

Traditionally, the prevailing mindset leaned towards marathon offset runs, seemingly the most cost-efficient option. However, upon closer scrutiny, it is evident that such runs merely reduced the cost per page of the offset printing process, not the overall TCO or obsolescence risks. The result of marathon runs included excessive work in progress (WIP), larger paper inventories, damaged prints, print overruns, and unsold books occupying valuable storage space. The transition to inkjet printing and roll to finishing options not only addressed these issues but also leads to a reduction in the print production and warehousing footprint, which also can be calculated. Admittedly, calculating the various costs involved remains a subject of debate.

There are other risks to consider, but those are too controversial to discuss. Nevertheless, it is crucial to recognize that each case warrants a “big picture” analysis. You are right, the days when CAPV or InfoTrends could provide a blanket statement like "the typical break-even is 5000 sheets." Today, a comprehensive assessment, considering the unique characteristics of each printing scenario, is required.

Thank you once again for shedding light on this vital discussion, which resonates deeply with many professionals engaged in the printing industry. Embracing a well-informed approach that acknowledges the shifting dynamics of print / finishing technologies and diligently examines costs and risks is paramount to staying competitive in this ever-evolving landscape.

By Elizabeth Gooding on Aug 01, 2023

Howie - I know you have done a lot of analysis of this type over the years so I don't take your praise lightly. Thank you. I think this type of analysis is overwhelming for many people so they should be aware that there are people like you, and several of the contributors to WhatTheyThink and Inkjet Insight that can help do the math for them. Thanks again for the positive feedback. I really appreciate it.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free