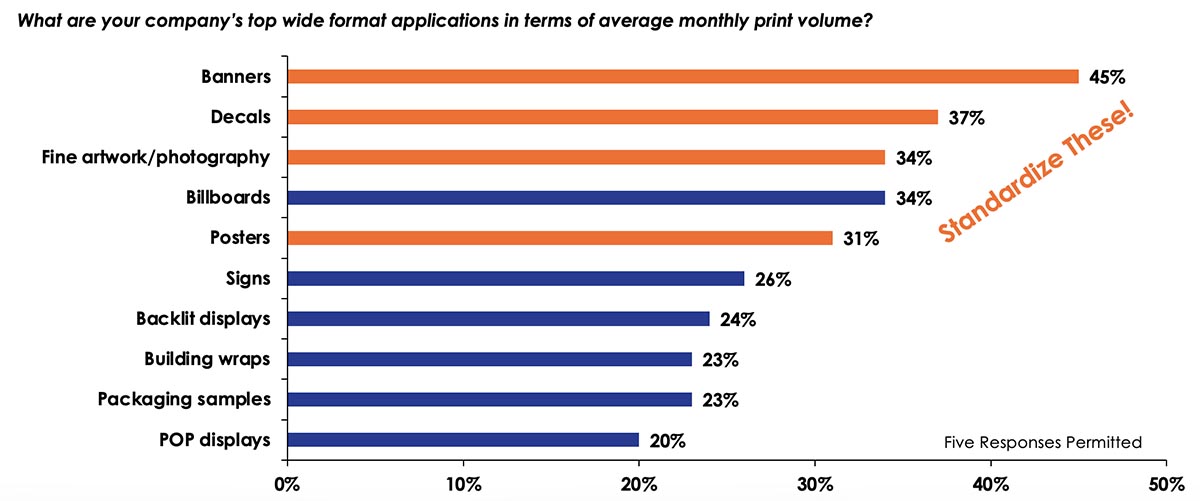

- Even though one buyer’s needs will often differ from another’s, certain in-demand products can be standardized to streamline the buying process.

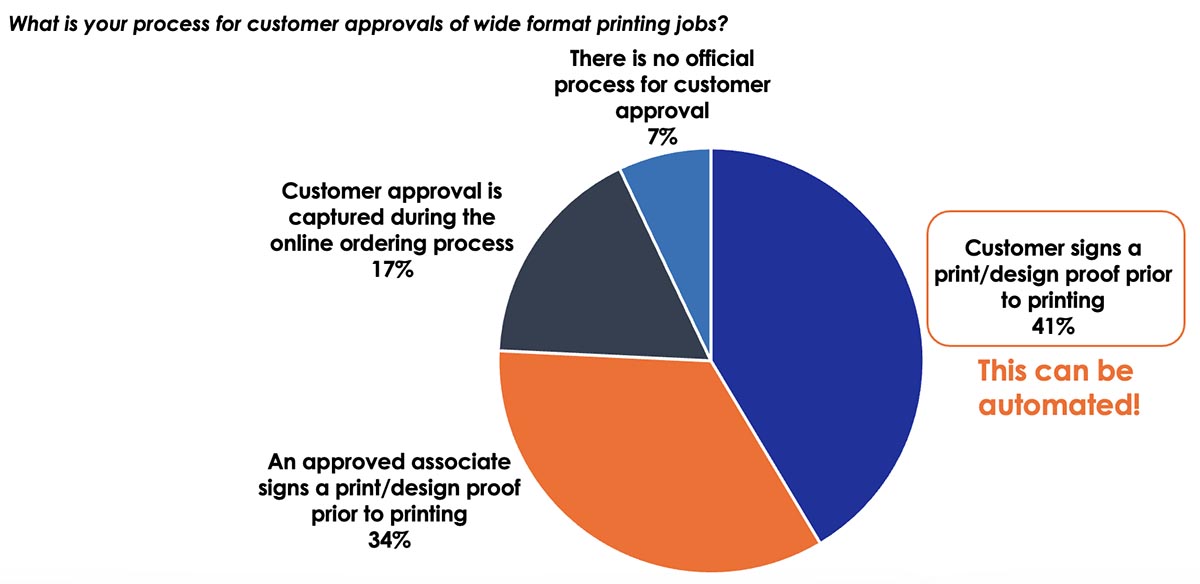

- By taking the time to audit your approval process and automate where possible, you can free up your design team so they can focus on more intricate and specialized projects.

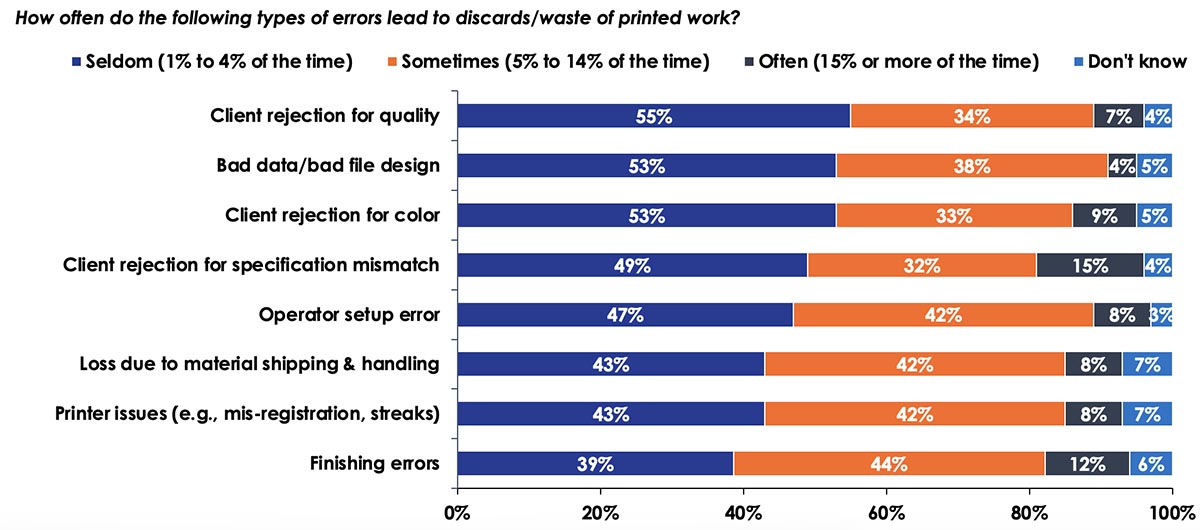

- Consider trying “Empathetic Efficiency” by seeking bottlenecks and inefficiencies. Eliminating these tasks might improve operations while also cutting costs!

By Eric Zimmerman

Introduction

As a global community of consumers, the so-called “Amazon effect” has truly taken over—we want (and in many cases expect) everything that we purchase to be readily available and delivered right to our doorstep with minimal delays. Some of you might remember the character of Veruca Salt from Willy Wonka & the Chocolate Factory. Although her behavior and famous quote “Don’t care how, I want it NOW!” were meant as a cautionary tale that instant gratification isn’t always best, her line is 100% accurate when it comes to our current purchasing preferences.

The ever-increasing demand for immediate delivery is creating some unique challenges for today’s print service providers (PSPs). Wide-format print jobs have become especially challenging because they often require a great deal of customization, personalization, and design modifications. This article discusses some top strategies that can help PSPs to manage the turnaround expectations of today’s print buyers.

Strategy #1: Standardize Some Offerings

Even if they have a strong online presence, most wide-format PSPs are not running exclusively online businesses. There is usually a good deal of customer interaction required for PSPs to create the products and applications that best satisfy a buyer’s unique needs. Even though one buyer’s needs will often differ from another’s, certain in-demand products (e.g., banners, decals, art/photo prints, posters) can be standardized by size, carted online, personalized with the customer’s uploaded graphics, and paid for up front. These parts of the process require very little customer interaction, so they can be streamlined. In addition, since most of these applications are regularly produced, they can easily be dovetailed into regular production runs throughout the day.

Figure 1: Highest Volume Wide-Format Applications

N = 137 Respondents

Source: Big Picture Magazine Wide Format Application/Utilization Study; Big Picture/Keypoint Intelligence 2022

Strategy #2: Automate Your Approval Process

At this point, it seems unreasonable to expect a wide-format PSP to become 100% automated—there are far too many variables to consider in a custom environment. That said, there are some steps in the process that, if automated, have the potential to dramatically increase efficiency.

Creating a semi-automated (or fully automated for the standardized offerings mentioned above) approval process is a great way to minimize the back-and-forth that is sometimes required to achieve sign-off from the customer. If you take the time to audit the approval process and automate where possible, you can free up your design team so they can focus on more intricate and specialized projects (also known as “the fun stuff”). Spending time on the “fun stuff” is certainly preferable to e-mailing 20 different iterations of basic applications.

Figure 2: Process for Job Approval

N = 137 Respondents

Source: Big Picture Magazine Wide Format Application/Utilization Study; Big Picture/Keypoint Intelligence 2022

Strategy #3: Streamline Production Workflow

As shown in the Figure below, overall error rates are tolerable but have room to improve. According to Keypoint Intelligence’s research, the current error rate stands at about 9%, but under 5% would be ideal.

Figure 3: Frequency of Errors Leading to Waste

N = 137 Respondents

Source: Big Picture Magazine Wide Format Application/Utilization Study; Big Picture/Keypoint Intelligence 2022

The question is, how can a PSP achieve an error rate of under 5%? While automation or equipment upgrades might help, I’d like to suggest another approach. Earlier this year, I was introduced to a term known as “Empathetic Efficiency.” This term came about when the CEO of a major restaurant chain in the United States went through the day-to-day operations with his kitchen and waitstaff to look for bottlenecks and inefficiencies. When he took the time to examine the established practices, he found that there were some processes in place that the members of his staff absolutely hated! These tasks only persisted because of a “that’s just how we’ve always done things” mentality; there was no benefit to the restaurant’s patrons. By eliminating these tasks, the CEO was able to make his operations more efficient. Even more importantly, he was able to create a more positive workplace while also cutting costs!

The Bottom Line

Print buyers want to do business with firms that make the buying process efficient and enjoyable, and PSPs need to deliver! Start by standardizing certain offerings and automating the approval process. Next, rather than doing things in a particular way “just because,” give Empathetic Efficiency a try. Identify the processes that are slowing things down or creating problems for your employees. These outdated processes may be happily discarded by your production team, freeing them up to spend more time on “the fun stuff!”

Eric Zimmerman is the Principal Analyst of Keypoint Intelligence's Wide Format Printing Consulting Service. He develops annual global market forecasts for hardware and supplies used in the wide format printing markets. He is responsible for conducting multiple primary research studies annually in the wide format market both on a custom basis and as part of Keypoint Intelligence's syndicated research.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free