Welcome to day two of WhatTheyThink’s coverage of our fourth annual Technology Outlook Week. Yesterday, we kicked things off with digital printing, presented by WTT European section editor and Inkjet Insight contributor, Ralph Schlözer. Today we turn to the session on software and workflow presented by Pat McGrew, managing director of the McGrew Group Inc., and Ryan McAbee, chief analyst at Pixel Dot Consulting. The webinar was sponsored by Global Graphics and Ultimate Technographics. You can watch the entire webinar here.)

The topic was a “A Framework for Automation.” While the term “framework” sounds technical, it’s really a series of questions that serve as a guide to unlocking the power of automated workflow.

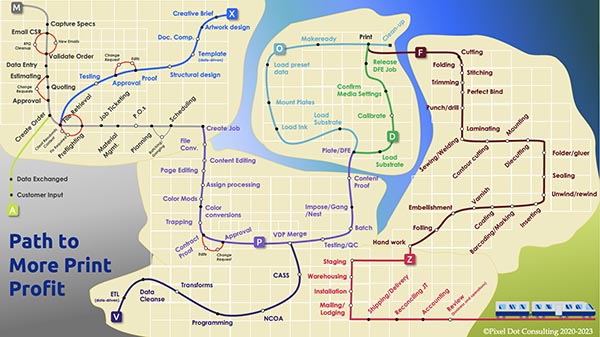

“You would be hard pressed to find a printer who doesn’t know they need automation,” says McAbee. “But with the average printer having dozens or more product lines, each with 50 or more high-level steps (then many more sub-steps beneath), it seems daunting. How do you even get started?”

The answer is to break it down into smaller pieces.

What’s Your Goal?

The first step, according to McGrew, is to identify your goals for automation. For some, it might be full automation. For others, it might be “islands” of automation. For each printer, automation might look quite different.

That’s why printers are encouraged not to get caught in the trap of thinking that it’s all or nothing. “This is still an industry with a lot of physical and mechanical processes—each shop also has its own variables with its staff and customers’ workflows,” says McAbee. “It’s important to take a deep breath and realize that full automation may not be the end goal for everyone.”

If a shop is running a completely manual workflow, for example, the next step might be to automate key processes, for example, with the goal of moving to semi-automation down the road. If a shop already has islands of automation, it might be the time to take the next step closer to end-to-end automation.

The point is, automation can be a step-by-step process.

1. Identify Your Biggest Challenges

So where do you start? According to McGrew and McAbee, you start with the obvious. Identify the major problems—the ones repeated inside your shop day after day. “You are looking for problems that are systematic, that happen routinely, because that’s where you’re going to see the greatest impact,” says McAbee.

As management, you have a sense for what these are. But don’t stop there.

- Ask your production team. (They live it every day.)

- Ask your sales team. (Are they are losing jobs because it takes too long to get back quotes?)

- Consider unspoken signals from your customers.

“Once you identify the key issues, you can start asking the ‘who,’ ‘what,’ ‘when,’ ‘where,’ ‘how,’ and ‘why’ kinds of questions,” says McAbee. “Go below the surface. You want to go, say, three levels deep on each one, because then you'll start getting to the root of the real issue. Sometimes it’s not what you think.”

2. Quantify the problem with numbers.

Put numbers to the bottlenecks and inefficiencies when possible. For example, if you identify one of your key bottlenecks as taking too long to get back estimates, figure out what that is costing you. How many estimates do you give each day, on average? How much time does it take to create each one?

3. Define Success

Next, define success. What does that look like to you? Is it reducing estimating time by 30%? Is it increasing throughput by 15%? Or is it something softer, like not having your estimating team working until 11 PM every night?

“‘Success’ is whatever threshold you think makes sense for you and your customer base,” says McAbee.

4. Map the Process

Now it’s time to start identifying areas where automation can help. Start by putting your workflow down on paper. You can do this from memory, or you can actually “walk” the workflow, moving like a job ticket from order entry to delivery, documenting each step along the way.

“At each step, identify bottlenecks and inefficiencies,” says McGrew. “How much time are you losing at each step?”

McAbee and McGrew used the example of estimation, with a hypothetical shop taking too long to return quotes. “Once you have the process documented, you can start to figure out the root of the problem,” says McAbee. “Do you need new software? Do you need integration between systems? Or is it your people? Do you need to put a process in place because everybody's doing things a different way?”

This is where “workshopping” comes in. When workshopping, you gather a team to brainstorm and get into problem-solving mode. By incorporating the perspectives and experiences of different employees at different levels of the organization (production, sales, customer service, management), you can often uncover issues (and solutions) that you would not have discovered in a vacuum.

Sometimes the fix requires a simple capital investment. For example, are you using a fancy database that you built or yourself or a highly customized Excel spreadsheet that only one or two people can use? If so, would you be better off using a standardized tool that can be used by multiple people?

Other times, the root of the problem has nothing to do with software or hardware. “You might find, for example, that delays are caused by employees who are trained on your estimating suite but who are not all using it the same way,” says McGrew. “Or maybe there is too much back and forth communication between your customer support reps, your salesperson, your estimator, and even the customer, because there's no process in place for getting critical job specs.”

All the while, keep in mind that the workflow isn’t linear. McAbee describes a printer’s workflow as being like a looping subway system where trains are following the same schedule, but are constantly changing tracks.

“If you are documenting it yourself, it helps to whiteboard it,” he says. “Create a wall of sticky notes, or whatever method you want to use. Initially, you're just simply documenting—what's going on here? Then you start asking yourself, is this the right process? Is there a better way to accomplish the same thing? Is there a way to optimize and automate it?”

5. Identify the Available Tools

Once you have a firm grasp on the priorities, start making a list of the tools you already have in-house. Take a formal inventory.

“You might think you know, but as time passes, you lose track of the details,” says McGrew. “You might have equipment presets, setting recall capabilities, or quality control sensors you had forgotten about. Or there might be machine learning for autocorrections you didn’t know you had.”

On the software side, look for software that is underused or unused, has add-ons or apps available, and turnkey partner solutions.

Be as detailed as possible. Write down the name of the software, the version, and other details. Then do your research. Some of your solutions may have APIs or other integrations that they didn’t have before. You might have simple fixes right at your fingertips.

As part of your inventory, make sure to include your data. “What is available? ” says McAbee. “What software is the data keeper? Is it structured or unstructured data? What format(s) is it in?”

Make It a Team Approach

Whatever approach you use, both McGrew and McAbee emphasize the importance of creating a cross-functional team. McAbee notes that he has rarely, if ever, worked with a company that hasn’t had ‘a ha!’ moments from using this approach. “As the team is sitting around brainstorming, putting down the way they think things work on paper, somebody raises their hand and says, ‘Oh, nope, that's not quite right. We’re actually doing it this way. (Or haven’t done it that way in years),” he says. “This is where you really start learning.”

“The more transparency you have with your team, the more they will help you identify logical milestones and timelines,” agrees McGrew. “Because of their diverse experience and knowledge, they may be able to identify problems and offer solutions that you might not have come up with on your own.”

While there is no “one size fits all” solution, the goal is to create a standard operating procedure (SOP) that is unique to your organization. Not only do you create a higher level of efficiency, but you can often identify opportunities for greater profitability. “During the estimating process, for example, maybe there is an opportunity to upsell on a different kind of paper or a different kind of finishing,” McGrew continues. “Start to build the revenue streams with suggestions for incremental adds as part of the estimating process. That’s an often missed opportunity.”

McAbee notes that this is where a system like a web print system can be particularly helpful, since most have cross-sell functionalities built in.

Start with What You Have

Once you have an inventory, rather than going out and investing in new automation, both McGrew and McAbee suggested starting with the tools you already have and may not be taking advantage of.

“One of the biggest mistakes we see printers make is either not using or underutilizing the software already in their shops,” says McGrew. “Even if the functionality is enabled, maybe the people who are using it have not been trained on it. So they're just using it incorrectly or inefficiently.”

McGrew notes that, in these cases, you've already made the investment. So if your vendor wants to charge you a little bit to come in and train your people how to use it, “it could be a really good investment,” she says.

(Or, McGrew adds, you can do a search on YouTube. “You’d be surprised how many vendors have put amazingly useful videos out onto YouTube that may preclude needing to hire their live trainers to do a one-on-one class for your team!”)

Working toward automation also requires looking for opportunities to integrate different pieces of software that you might not have considered or didn’t realize was possible. “You may have bought two pieces of software five, 10 years ago that today offer API- based integrations,” say McAbee.

Examples of top places to find efficiencies?

- Job submission. (Are you still receiving jobs by email? That is time consuming, invites a lot of variability, and opens the process to error.)

- Inventory systems. “If you have people running out to the warehouse to count how many pallets of paper you have on hand, that's not the best use of their time,” says McAbee. “Time is expensive. Integrating your inventory systems with your estimating systems is one of those quick ‘bangs for your buck’ and very often easy to accomplish.”

- Job scheduling. “If the job scheduling information is available to the estimating system, that is a huge time saver and protects you from potential job conflicts and missed deadlines,” says McGrew. “Those are the kinds of integration points that we're talking about.”

If there are not existing APIs for the desired integrations, there might be an SDK (software development kit) that requires you to write some code. “Typically it's very straightforward and your vendors may be able to help you,” says McGrew.

What’s the Path Forward?

On this journey, there is a lot of help available. You can do it yourself, work with your vendors, or engage a third-party consultant.

“Your vendors are a wealth of information,” says McGrew. “Many of them have dedicated teams who will be delighted to have a conversation about how to tighten your workflow, make it more efficient, optimize it, and integrate it with other workflows that you have.”

McGrew notes that while printers may not look to their vendors as the first phone call they make, “We work with a lot of the vendor teams, and there are some really smart people with really great, diverse experience. It is always worth having a conversation with them, even if you haven't talked with them in years.”

Beyond expertise, one of the other values of working with a vendor or consultant is that they see a lot of different shops and can leverage this experience in your shop. “Because let's face it, you are in a competitive market where everybody's got the same printing and finishing equipment,” says McGrew. “One of the best ways to differentiate yourself is on efficiency.”

Have the expertise to do it yourself? Start with a risk assessment. Make sure your internal IT team has the expertise, not just in the individual components, but in the programming and application integrations, as well. Also make sure they have the bandwidth to take on an integration. You don’t want it to conflict with other mission-critical projects, such as customer onboarding or key customer experience features you're trying to roll out.

Finally, remember to look at the overall costs that include your time, disruption, and unwelcome surprises. When you take everything into consideration, sometimes they least expensive solution…well, isn’t.

Wrapping It Up

Regardless of the path you choose, don’t be afraid to take the plunge—and don't try to take on too much at the beginning or it can lead to paralysis. Have a clear goal, create a cross-functional team, and get the right numbers (“Because the worst thing you can do is automate the wrong thing or automate to the wrong set of KPIs,” says McGrew.)

Finally, focus on integration, integration, integration…because you can't automate before you integrate.

Next time, we look at labels and packaging technology.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free