This prolonged period of paper shortage has required patience, persistence, and creativity from both printers and their customers. This creativity will pay off in the long run since, by all indications, this will become our new normal. As discussed in WhatTheyThink’s recent article, “What Are You Telling Your Customers About the Paper Shortage?”, those paper mills that have closed and papermaking machines that have been converted to more profitable grades aren’t coming back. Barring the occasional plant being opened under special circumstances (such as the potential reopening of the Verso mill in Wisconsin), paper supply will continue to shift towards packaging (i.e., the Green Bay Packaging mill) and specialty papers, leaving commercial printers to rethink how they and their customers approach production print.

To see get a sense for how the industry is responding to the changing environment and what the “new normal” might look like, WhatTheyThink asked readers and other members of the industry to respond to a short, three-question survey asking about the most popular alternatives when traditional stocks are not available, how customers are responding to suggestions about alternatives, and how printers explain the situation to their customers.

Here are the results:

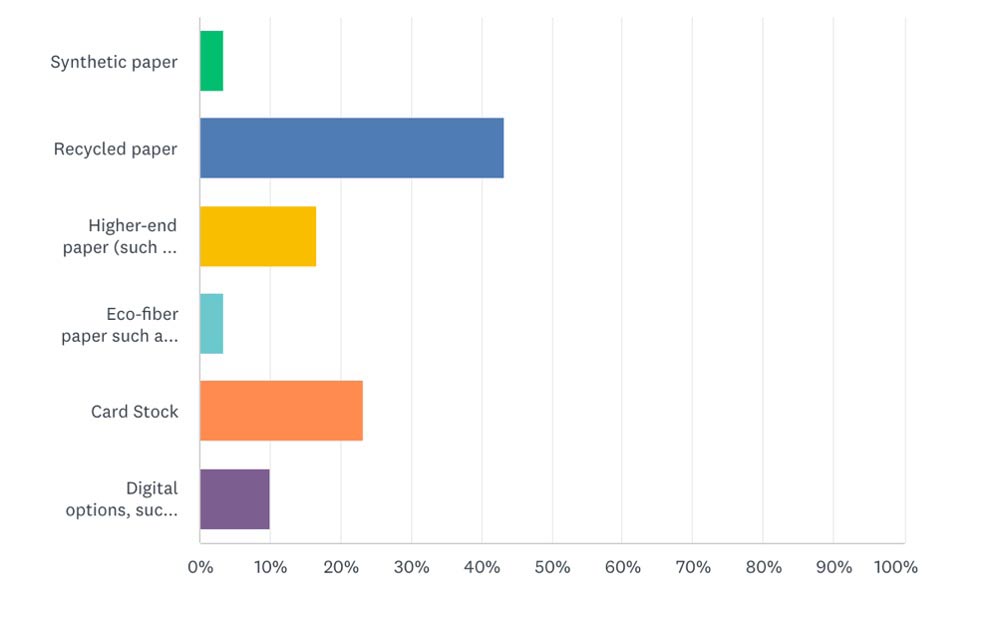

- When traditional paper stock isn't available for commercial printing projects such as direct mail, brochures, and marketing collateral, which alternatives are you most likely to suggest to your customers?

|

Synthetic paper |

3% |

|

Recycled paper |

42% |

|

Higher-end paper (such as cotton) |

19% |

|

Eco-fiber paper such as hemp, kenaf, or bamboo |

3% |

|

Card stock |

23% |

|

Digital options (such as email) |

10% |

That recycled paper and card stock came in first and second by a wide margin is not a surprise. This reflects not only what is available, but the direction in which the paper industry has been moving for a long time.

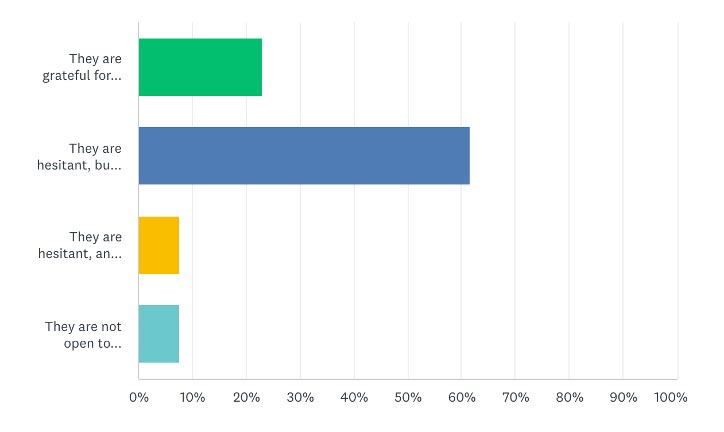

- When you suggest alternative substrates, how do your customers typically respond?

|

They are grateful for the suggestions and willing to embrace alternatives. |

22% |

|

They are hesitant, but willing to consider other options once those alternatives are explained to them. |

59% |

|

They are hesitant, and it takes some convincing to get them to consider alternatives. |

12% |

|

They are not open to suggestions. They'd rather have a longer lead time. |

7% |

Not included as an option but added as a comment from one survey respondent was, “They are switching to digital.”

Some of these answers, we can assume, are influenced by the printer’s ownattitude toward the shortage. If the printer presents the shortage as short-term, then customers will naturally be more hesitant to try alternatives, thinking they can just wait it out. If printers take the approach of explaining the global supply chain issues, customers are more likely to be willing to explore other options because they understand that this is the new environment they are in.

- When customers complain about limited stock and higher prices, how do you explain it to them?

As expected, there was a range of approaches, but essentially, responses fell into two camps: blaming short-term issues related to the pandemic and inflation; and willingness to engage in conversation about the difficult realities of a fundamentally changing landscape for paper. Here is a representative selection of responses:

We have a document of all the paper mills that have shut down over last 10 years with no new capacity built unless for packaging, as your article explains.

I have tried to share the current market situation with my clients every step of the way so that they are not shocked or surprised by availability and pricing changes.

It’s a global issue.

Most understand the worldwide impact due to the pandemic. For the most part, clients respond well to alternatives and price increases.

We’re in this together with the entire world. Availability is slowly improving!

Supply and demand and the pandemic. We compare it to the toilet paper issue way back when pandemic started. Oh, the memories of that shortage!

I blame the COVID shutdown.

This is not permanent, [so plan ahead]. Send orders for the next 180 days.

(These last three responses are certainly explanations that customers will understand and relate to, and in the short term, they may pacify their frustration. However, it’s worth noting that when the situation doesn’t return to pre-pandemic levels, these customers will be coming back for more answers.)

Reply with an alternative solution presenting it in way that makes them say WOW!

Unfortunately, I'm in the magazine business and the magazine is funded by ad sales. In this economy, I'm not able to pass the increases to advertisers. This will eventually put many small publishers out of business.

That we are all faced with the challenge. I try to alert my clients to be aware of the current situation and try to plan well in advance to have a better chance of meeting their needs.

Inflation.

Limited stock isn’t an issue now as much as prices. I explain about fuel costs/diesel remaining high and that paper’s cwt price to the printer includes freight.

Production capacity has been altered.

Mills have shut down or been converted to making other, more profitable products.

I find that the best way is to discuss the value of the newer / more expensive media. Especially when it comes to direct mail, etc. It eliminates extra finishing. At the end of the day, it actually costs less.

We're unable to get supplies from our standard vendors and have to seek paper elsewhere, which generally reduces options.

Offering options, including bulk buying.

The supply chain is still tight because mills have shut down or shifted to packaging material. We work closely with our paper suppliers to offer you the best options available.

Give them a brief education about how expensive/difficult it is to start up a paper mill as well as the mills producing higher profit items.

Play the supply chain card as long as possible, plus mill closures and reduced manufacturing capacity.

Less paper mills than ever before making paper. The demand is higher than the supply.

Supply chain issues, like a lot of things the past 18 months. Paper mills have shut down or repurposed to packaging grades. Imports limited due to logistics issues. Too much demand with not enough supply.

We tell them exactly what your article says and explain that it is industrywide.

That this is the new normal. We adjust and move forward.

Market conditions (mills shut down or shifting to packaging) that started before the pandemic were exacerbated by logistic issues related to the pandemic. Mills won’t go back to unprofitable products.

Have talked about the Amazon effect—meaning paper mills are producing more packaging like Amazon packaging.

Welcome to the New Normal

What’s next? As the one respondent said, “We adjust and move forward.” It may be easier and more pacifying customers to point to short-term conditions, but commercial papers aren’t like other products impacted by the pandemic. Customers will figure that out eventually, if they haven’t already.

Printers taking the time to explain the market realities are positioning themselves and their customers well for the long term. Nobody wants to be the bearer of difficult news, and a fundamental shift in the nature of the paper market is difficult news. But these printers’ customers will be prepared, and they will be used to turning to their printers are problem-solvers and alternative-finders, deepening that trust and that relationship.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free