- When the pandemic forced employers to pivot to a work-from-anywhere model, cloud computing and software-as-a-service solutions eased the transition.

- A print shop’s customer relationship management system may have hundreds, if not thousands, of contact records and critical pieces of information about clients.

- Print can further link the digital benefits of augmented reality to the physical world by providing the trigger to initiate the experience through a quick response code or other techniques.

By Ryan McAbee

Introduction

The pace of change in the printing industry has been marked by peaks of innovation followed by years of continuous improvement. The convergence of modern technologies can enable breakthroughs that were not previously possible, and at a faster pace than before. At Keypoint Intelligence, we have identified five core technologies (cloud computing, big data and analytics, artificial intelligence, robotics, and augmented reality) that will ultimately lead to mostly—if not fully—autonomous print production. This might seem like a far-off science fiction movie, but this transition will likely occur by the end of this decade because each of these technologies has a compounding beneficial effect on the others. For example, large amounts of data are the fundamental building blocks for machine and deep learning that improves the accuracy and capabilities of artificial intelligence (AI). Simply put, one technology improves the other.

While the terms “smart factory” and “Industry 4.0” are commonly used as umbrella terms for these technologies, they often lack enough emphasis on the intersection and dependencies between technology, processes, and people. We prefer to describe the path forward for the printing industry as Smart Print Manufacturing (SPM), which combines advanced technologies, like AI, with effective manufacturing processes to achieve the goal of semi-to-fully autonomous print production. This article explores the current state and future implications of our five core technologies for SPM.

The Five Core SPM Technologies

Cloud Computing

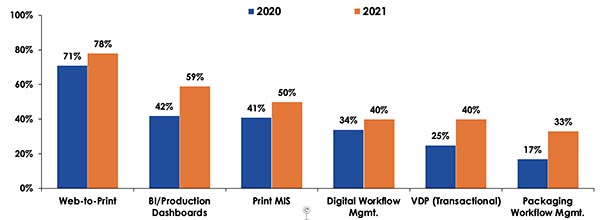

During the height of the pandemic, we were able to recognize one of the primary value propositions of cloud computing--accessibility. When employers were forced to pivot to a work-from-anywhere model, cloud computing and software-as-a-service solutions eased the transition for businesses that had already adopted the cloud services. Our North American Software Investment Outlook research found that the use of cloud-enabled software increased by as much as 94% year-over-year. Even cloud-heavy web-to-print (W2P) software experienced a 10% gain as more PSPs needed to provide socially distanced, online ordering. Although the pandemic certainly accelerated the adoption of cloud computing, this trend has staying power.

Figure 1. Year-Over-Year Increase in Cloud Deployment

N = Varies; Base: Respondents who currently own these software products

Source: NA Software Investment Outlook, Keypoint Intelligence 2020/2021

Big Data and Analytics

When someone mentions big data, the printing industry with its manufacturing base may not come to mind as much as technology companies like Google, Facebook, and Apple. If you look beneath the surface of any printing operation, however, you’ll realize that a lot of data is being generated. A print shop’s customer relationship management (CRM) system may have hundreds, if not thousands, of contact records and critical pieces of information about clients. The print shop’s management system keeps quotes, jobs, and shop floor data to manage and streamline production. The biggest generator of data is likely the equipment on the shop floor that could be collecting information on the jobs, machine usage, and environmental conditions, while also analyzing the output to ensure quality.

Traditionally, the data within the print shop is turned into reports pulled by key staff and management to monitor key operational and financial metrics. In the last few years, print management information system (MIS) providers and equipment manufacturers have started offering data analytics. Some of these are built on top of well-established data analytics platforms like Microsoft BI, Sisense, or Izenda, where data can be gathered from many sources. The downside is that these platforms often require professional services to integrate multiple data sources.

Manufacturers have mostly focused on capturing data locally or in the cloud from Internet-connected equipment (assuming customers opt-in) for use in their own data analytics tools. While these original equipment manufacturer (OEM) tools can provide insights related to equipment uptime, overall equipment effectiveness (OEE), ink consumption, and other indicators, PSPs need a more comprehensive view of their entire operations.

Going forward, we believe data and interchange standards along with growth of industry technology platforms will alleviate the siloed state of today’s data analytics options.

Artificial Intelligence

Our industry is in the beginning stages of using the vast amount of machine data generated to improve the operation, quality, and autonomy of the printing process. Using large amounts of data, algorithms can effectively train machines to accomplish a particular task. This is a part of AI known as machine learning.

There are a few use cases for machine learning that have come to market over the last year. HP and Ricoh are using visual inspection systems and machine learning to identify, classify, and correct issues in print output. This type of solution uses algorithms and, in some cases, user feedback to improve the accuracy and speed of detecting print defects. Depending upon the issue, the software can take corrective action, such as compensation for a clogged printhead, or queue a reprint if needed. Due to AI, less skilled operators are needed even as quality is assured. In a different use case, Xerox PredictPrint Media Manager leverages AI to correlate and share up-to-date settings for different media when other users scan the paper ream’s barcode. The solution automates settings for size, type, color, coating, and weight with the simplicity of scanning the barcode, loading the paper in the printer, and then completing the process with wizard-driven selections as needed.

Robotics

According to the International Federation of Robotics, installation of industrial robots more than tripled globally from 2010 to 2019, putting the total installed base over two billion. There are several trends that are lowering previous barriers to adoption and making robotics more accessible. The most impactful change has been a steady decline in cost along with a steady rise in variation and capabilities.

To date, the use cases for the production printing are more limited and programs from OEMs are still works in progress, with some offering robotic automation for material movement. Technology-forward PSPs with sizable or complex fulfilment operations have started adopting Automated Guided Vehicles (AGVs) for their warehouses. We expect adoption to accelerate over the decade, led by a desire to increase productivity while minimizing or shifting labor costs to higher value tasks.

Augmented Reality

Augmented Reality (AR) is an enhanced version of reality created by overlaying a digital layer, mainly for purposes of education or entertainment. Print can further link the digital benefits of AR to the physical world by providing the trigger to initiate the experience through a quick response (QR) code or other techniques. There are many use cases from video explainers on critical customer documents to more creative AR that allows customers to experience a product.

For SPM, we focus on AR that enables or assists print production, not AR that is part of the printed product. The most prevalent use case is AR to diagnose and service printing equipment that can be used by the OEMs service technician or by the end-user. The experience enables the end-user to identify parts and can provide instructions on how to repair or replace items.

Going forward, we expect AR to play a key role in bridging the physical and digital worlds using digital twins to visually model different scenarios of the print manufacturing process. AR could assist in modelling a new physical layout of the print shop or predict bottlenecks throughout the production processes based on varying print volumes and application mix.

The Bottom Line

Keypoint Intelligence believes that the printing industry is reaching another peak in innovation, similar to past moments of creative destruction that lead to new opportunities. During moments of creative destruction, the new replaces (or displaces) the old while creating new opportunities.

The impact of SPM technologies is likely to arrive faster and be more disruptive than those that came before, since each can amplify the effect of the others. Rather than fearing this transition, it is more productive to focus on some positive effects that have already occured. Cloud computing displaces the need for local IT infrastructure and administraiton, but opens access to the growing hybrid and remote workforce. Big data and AI will disrupt creative and analytical tasks now performed by people, but will enable us to make better use of our time for higher value work. The key for PSPs is to always plan for the future by identifying and adopting transformative innovations to successfully transition from the old to the new.

Ryan McAbee is the Director of Keypoint Intelligence’s Production Workflow Consulting Service, which focuses on providing technology, business, and market insights to clients in the Digital Marketing & Media and Production Workflow markets. In this role, he is responsible for conducting market research, market analysis and forecasting, content development, industry training, and consulting with print service providers.

Discussion

By Cliff Hollingsworth on Jun 10, 2021

There needs to be a full on debate/discussion about the state of the industry in a meaningful way. Other media outlets, in my opinion, are completely out of touch and I have always had a faith in the perspective of WTT.

This article caused me to pause. Reading this article gave me flashbacks as to why I stopped reading other industry material. How this was allowed to be published by WTT is beyond me. While I'm sure the research is sound, the conclusions are just too far fetched to be believable. Sure the technology is in place and yes cloud computing has indeed replaced local IT infrastructure in many applications, but c'mon, are we really reaching a peak in innovation? We haven't even fully understood the impact of inkjet out here in the real world yet, no matter what the pundits think.

I love WTT, but what happened to writing about the "real life" daily fight that we are all going through. If this industry doesn't realize that 2020 has changed us all forever, we're lost anyway. If you think that the struggle that companies are facing regarding WFH is tough, how about the answers to the questions about how printed materials will be consumed as our customers try and reconnect with their customers??? As our customers return to work in whatever fashion that becomes, I think the customer experience will be what wins or loses the project for printers moving forward.

Also, when are we going to actually have substantive discussions around recruitment/training/retention of young people in a diverse and meaningful way??? If we don't fill the talent funnel, we may indeed find ourselves letting W2P sites with automated workflows running our prepress functions and robots and AI running our presses and folders for us while the automated attendant handles the incoming calls.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free