Gallus One, Mastermatrix Debut for 150 Customers at HEIDELBERG’s “Summer Innovation Showcase”

Press release from the issuing company

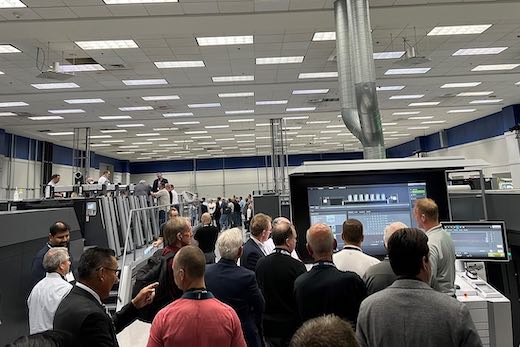

Kennesaw, Ga. – With a continued focus on the optimization of People, Processes, and Technology, HEIDELBERG USA welcomed over 150 customers from throughout North America to the Print Media Performance & Training Center (PMPTC) in Kennesaw, GA for its “Summer Innovation Showcase” held earlier this month. The event featured a variety of live demonstrations and seminars highlighting HEIDELBERG’s full product and service offerings for the commercial, packaging, and label segments and included the North American premiere of the Mastermatrix 106 CSB die cutter and world premiere of the Gallus One digital label press.

Innovation Across the Product Portfolio

Attendees explored HEIDELBERG USA’s robustly equipped PMPTC featuring the Speedmaster XL 106-8P+L, Speedmaster CX 104-6+L, Stahlfolder TH 82 with new robotic P-Stacker, Stahlfolder KH 82, POLAR 137 System 200 and POLAR 78 cutter, Easymatrix 106, Diana Easy 115, Versafire EP & EV and Prinect Production & Business Manager. “We called this event ‘Innovation Showcase’ to demonstrate the efforts we’ve taken to stay at the leading edge of product development to support our customers’ pursuit of efficiency,” said Felix Mueller, President of HEIDELBERG North America, “but we are more than machines. We also wanted to highlight innovations – like our approach to industry training – that aren’t purely technologically driven.” In addition to equipment and software demonstrations, customers had the opportunity to learn about HEIDELBERG’s Operator & Maintenance Training courses and toured the impressive renovations the company has made to its Training Center since the facility launched over a year ago.

Making its North American debut at the Innovation Showcase, the Mastermatrix 106 CSB, with speeds up to 9,000 sheets per hour, is HEIDELBERG’s newest and fastest die cutter from partner Masterwork. In addition to faster running speeds, the machine features a variety of innovations all designed to maximize efficiency and user-friendliness and minimize makeready times. Machine highlights include a cam driven die cutting station for optimized sheet transfer, a motorized feeder head with built-in rear joggers, and the new EasyRake system that makes positioning and fastening individual delivery non-stop swords quick and easy. Featuring Quicklock tooling throughout, the Mastermatrix offers maximum flexibility for customers – accepting tooling from other manufacturers’ die cutters. Additionally, operators are always in control as they monitor production with cameras located at strategic points in the machine.

Center stage at the Innovation Showcase was HEIDELBERG’s highly anticipated Gallus One digital press. The new roll-to-roll press, which utilizes Fujifilm Samba printheads, prints CMYK+W up to 13 3/8” (340mm) wide at 98 ft/min (30 m/min) or 230 ft/min (70 m/min). With 1200 x 1200 dpi resolution, the Gallus One achieves offset like quality and 85% white opacity at top running speed. “The product development team really thought of everything when they designed this machine,” said Dan Maurer, Vice President of Digital Product Management for HEIDELBERG USA. “Ease of use, reliability with 95% uptime, substrate flexibility, and opaque white without the need to slow down the machine or use a primer or protective coating.” Utilizing HEIDELBERG’s Prinect Digital Front End, the Gallus One features a compact 11 x 20.8 ft. footprint and includes a live video monitoring system to ensure quality during the press run. “This machine really fits into a variety of different production environments,” said Maurer, “and has a surprisingly high crossover point with traditional flexo printing.” A key automated feature of the Gallus One is the patented substrate web control tension in the Digital Print Unit (DPU). During the head cleaning process, the inkjet heads remain stationary as the web moves down – holding the web tension as the cleaning system moves into position. This function, which was designed to maximize print quality and minimize waste, requires zero operator intervention and is controlled completely by the machine’s software.

- KYOCERA NIXKA INKJET SYSTEMS (KNIS) INTRODUCES BELHARRA, THE NEW WAVE OF PHOTO PRINTERS

- New RISO Printing Unit Offers Easy Integration for Package Printing

- March 2024 Inkjet Installation Roundup

- Inkjet Integrator Profiles: Integrity Industrial Inkjet

- Revisiting the Samba printhead

- 2024 Inkjet Shopping Guide for Folding Carton Presses

- The Future of AI In Packaging

- Inkjet Integrator Profiles: DJM

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free