- Some primitive examples of AR applications include Pokémon Go, as well as Facebook and Snapchat image filters.

- Using any mobile device, a consumer or business user can impose an image of a fully-rendered product into their intended space and immediately determine how it will fit.

- A printer enhanced with data analytics software can better “understand” itself and notify users when certain components require service. Using AR, the user can receive instructions on how to properly remove an old part and install a new one.

By Colin McMahon

Introduction

Several major technological innovations have had a transformative effect on the printing space. One such example is augmented reality (AR), a technology that superimposes a digital or computer-generated display (image, video, or words) onto the real world. While many may associate AR with futuristic headsets or science fiction settings, the reality is that most people already use the technology in some capacity. Some primitive examples of AR applications include Pokémon Go, as well as Facebook and Snapchat image filters.

At the same time, however, even mobile AR (AR applications created with smartphone and tablet interfaces) is more powerful than these simple apps would suggest. Although AR is still a young technology, it has advanced enough to impact multiple industries. AR enables a variety of improvements in the print space, and this article explores how AR is affecting the production print market.

Installation Made Easy

For vendors that specialize in selling production printing hardware, some of the challenge comes in the early stages of client communication. For instance, many vendors will want to fully see a product before they purchase it—partially so they can ensure that their facility has the required space for it. In the past, this has required production printer vendors to take careful measurements and provide a variety of data.

With AR technology, this process can be streamlined. Many companies already use AR to facilitate the installation of furniture and hardware. Using any mobile device, a consumer or business user can impose an image of a fully-rendered product into their intended space and immediately determine how it will fit.

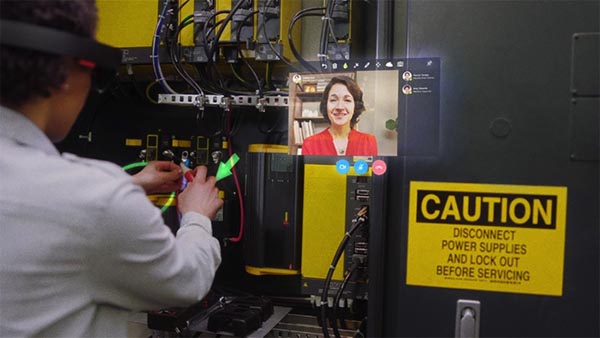

Nevertheless, this example does not represent the full value of AR in production print installation. Another cost factor is the installation process itself. Once a client has purchased a hardware device, the vendor will typically send out an expert to assist with the setup process. Although this process helps ensure that the client is satisfied with the purchase and enables a quick path to productivity, it can also be expensive and time-consuming. Furthermore, clients are essentially on their own once the expert leaves unless they contact tech support. With AR, travel is no longer necessary. An individual equipped with an AR headset can set up the printer as if the expert were with them in person—in part because the expert will still be remotely present.

Figure 1. A User Receives Remote Assistance with AR

Source: Road to VR

Most advanced AR headsets come with software that supports a remote link-up. A user can connect wirelessly with remote assistance and share their “screen” (in this sense, the screen is exactly what the user is seeing). This enables the expert to assist the user in real-time, providing relevant advice during any aspect of the installation process. This also means that one expert can oversee the installation of multiple devices in multiple locations on the same day—a dramatic improvement over the old system where travel was required.

Everyone is a Specialist!

This remote connection is only one way that AR enables every user to become a specialist. AR displays are designed with the real world in mind, meaning they can overlay information in practical, intuitive interfaces. For instance, if a technician is trying to use a production printer, their AR interface can show them exactly which parts of the machine to interact with, as well as educate them on which components perform which functions. Studies have already shown that this method helps users learn faster and better retain important information.

Figure 2. A Worker Learns Machine Operation with AR

Source: Forbes

Training has been listed as a major area for AR improvement for this reason. Users can clearly see all relevant information displayed in front of them at all times, enabling them to work in tandem with onscreen prompts, rather than from memory.

Improving Maintenance and Troubleshooting

AR does not exist in a vacuum, but rather works alongside other technological innovations. In this case, data analytics tools are advancing at a rapid pace. Some are designed for predictive analytics, understanding how a machine works and when to replace/repair parts as needed. A printer enhanced with this software can better “understand” itself and notify users when certain components require service.

A user with an AR display—headset or mobile-based—can see this notification and, through AR, be pointed to exactly where on the hardware the part is located. Depending on the accompanying software, the user can also be briefed with instructions on how to properly remove the old part and install a new one.

The Bottom Line

Although AR is a technology that is still in its infancy, InfoTrends believes it will see dramatic improvements over the next decade. Even now, though, the technology has already advanced to an extremely useful state. Production print hardware vendors can use AR to improve the usability and interactivity of their devices, ultimately making them cheaper and easier to own and operate.

Colin McMahon is a Research Analyst at Keypoint Intelligence – InfoTrends. He primarily supports the Business Development Strategies and Customer Communications services. He creates and refines much of InfoTrends’ written content, including forecasts, industry analysis, and research/multi-client studies. He also assists with the editing and formatting process for many deliverables.