(Click on the image below for a virtual tour of BIGink.)

Architects and wide format printers – an “odd couple?” Not at all! Wide format printers like

John Scholl, owner of

BIGink, are the “manufacturers” for creative firms working with commercial architects to brand interiors or to create exciting, informative, and educational spaces for museums and other informative facilities.

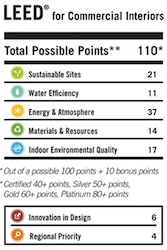

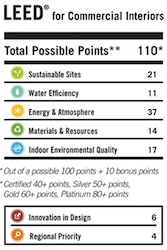

As builders and their designer partners become more involved in the

Leadership in Energy and Environmental Design (LEED) Green Building Rating System, developed by the

U.S. Green Building Council (USGBC) – decorative, informative, and architectural elements produced by wide format printers are getting more attention.

Interest and involvement is coalescing around the green building industry and that links materials used for furniture and furnishings to those used for building construction. Interest in LEED is growing on the West Coast and in the Pacific Northwest especially, where we are located in the heart of the lumber industry in the U.S.

LEED is a voluntary certification program built around a suite of standards for environmentally sustainable design, construction and operation of buildings and neighborhoods. Since its creation in 1998, LEED has grown to include more than 14,000 projects in the US and 30 other countries around the world.

Third party auditors provide verification that a building or community was design and built using strategies aimed at improving performance across all the metrics that matter most: energy savings, water efficiency, CO2 emissions reduction, improved indoor environmental quality, and stewardship of resources and sensitivity to their impacts.

The program was created to:

- Define "green building" by establishing a common standard of measurement

- Promote integrated, whole-building design practices

- Recognize environmental leadership in the building industry

- Stimulate green competition

- Raise consumer awareness of green building benefits

- Transform the building market

There are certification programs for new construction, existing buildings, schools, “core and shell,” and commercial interiors.

What does that mean to printers like BIGink? LEED establishes standards for sustainable design; however, those standards don’t really give a lot of credit to sustainably sourced or manufactured substrates for graphics used for branded interiors, unless a large amount of those materials are used. Large amounts as in the construction or renovation of a large hotel or dozens of retail chain interiors.

Because the architects and designers who are seeking LEED certification are already considering building materials, they do understand the value of environmentally sensitive substrates. Scholl is taking advantage of that sensitivity to position BIGink as the supplier of choice for signage and branded interiors.

New substrates that are made of recycled content, are recyclable, or made of biodegradable plastics are now available. Then add water-based, aqueous inks or UV inks and VOC emissions are pretty much eliminated. The wallpapers that BIGink offers don’t contain any petroleum products and are hung with water-based adhesives.

Wallpaper, for example, is a part of the building itself, and with planning can be easily removed and recycled. By applying appropriate primers, the papers will release from the wall without damaging the wallboard underneath. When the papers are removed, they are sent back to the manufacturer who “up-cycles” them to make floor mats and soundproofing.

“Why is BIGink offering these products?” asks Scholl. “It’s the right thing to do – and our clients are demanding it. We have to have green solutions for them.”

When you stand back and consider how the physical structure – the building – is evolving into modular segments that can be removed, re-purposed and recycled, the opportunities for wide format printing are suddenly expanding. Printed panels can be clipped to walls or used as dividers. Now that it is possible to print with process color and white on glass and Plexiglas, even more architectural elements lend themselves to print.

BIGink, for example, is experimenting with “ferro paper” which is a lightweight magnet-receptive material with a smooth white paper finish. Because it will readily accept magnets of all kinds, signs can have re-positionable elements that eliminate the need to reprint or replace the sign when one small change needs to be made.

Furniture is big part of “branded interiors” especially in food and hospitality applications, and Scholl is working closely with a designer to create an “eternal” table top for restaurants and lounges. An image printed on a tabletop made of engineered wood can be sanded off and reprinted when it is damaged or to change a promotion.

To Scholl, a sign is no longer a sign; a wall is no longer a wall. It’s hard to tell where one ends and the other begins; that makes for a very exciting time to be a wide format printer. BIGink is the “back shop team member” for architects and designers. And the back shop is a great place to innovate and experiment; to help designers understand what can be done.

Print is not dead; it is changing. Images are no longer pasted on a surface, they are part of panels that can be adjusted, modified, moved, changed, and reused. Architects and designers have a strong aesthetic sense and are looking to communicate in a physical space; whether they are creating a branded interior or providing directions and instructions.

High quality, environmentally sensitive images and substrates are a key differentiators for companies like BIGink today. Tomorrow’s differentiators may be any number of printing alternatives such as printed solar films and panels,

printed displays, 3D prototypes,

printed batteries, and even

interactive paper with printed circuits.

There are certification programs for new construction, existing buildings, schools, “core and shell,” and commercial interiors.

What does that mean to printers like BIGink? LEED establishes standards for sustainable design; however, those standards don’t really give a lot of credit to sustainably sourced or manufactured substrates for graphics used for branded interiors, unless a large amount of those materials are used. Large amounts as in the construction or renovation of a large hotel or dozens of retail chain interiors.

Because the architects and designers who are seeking LEED certification are already considering building materials, they do understand the value of environmentally sensitive substrates. Scholl is taking advantage of that sensitivity to position BIGink as the supplier of choice for signage and branded interiors.

New substrates that are made of recycled content, are recyclable, or made of biodegradable plastics are now available. Then add water-based, aqueous inks or UV inks and VOC emissions are pretty much eliminated. The wallpapers that BIGink offers don’t contain any petroleum products and are hung with water-based adhesives.

Wallpaper, for example, is a part of the building itself, and with planning can be easily removed and recycled. By applying appropriate primers, the papers will release from the wall without damaging the wallboard underneath. When the papers are removed, they are sent back to the manufacturer who “up-cycles” them to make floor mats and soundproofing.

“Why is BIGink offering these products?” asks Scholl. “It’s the right thing to do – and our clients are demanding it. We have to have green solutions for them.”

When you stand back and consider how the physical structure – the building – is evolving into modular segments that can be removed, re-purposed and recycled, the opportunities for wide format printing are suddenly expanding. Printed panels can be clipped to walls or used as dividers. Now that it is possible to print with process color and white on glass and Plexiglas, even more architectural elements lend themselves to print.

BIGink, for example, is experimenting with “ferro paper” which is a lightweight magnet-receptive material with a smooth white paper finish. Because it will readily accept magnets of all kinds, signs can have re-positionable elements that eliminate the need to reprint or replace the sign when one small change needs to be made.

Furniture is big part of “branded interiors” especially in food and hospitality applications, and Scholl is working closely with a designer to create an “eternal” table top for restaurants and lounges. An image printed on a tabletop made of engineered wood can be sanded off and reprinted when it is damaged or to change a promotion.

To Scholl, a sign is no longer a sign; a wall is no longer a wall. It’s hard to tell where one ends and the other begins; that makes for a very exciting time to be a wide format printer. BIGink is the “back shop team member” for architects and designers. And the back shop is a great place to innovate and experiment; to help designers understand what can be done.

Print is not dead; it is changing. Images are no longer pasted on a surface, they are part of panels that can be adjusted, modified, moved, changed, and reused. Architects and designers have a strong aesthetic sense and are looking to communicate in a physical space; whether they are creating a branded interior or providing directions and instructions.

High quality, environmentally sensitive images and substrates are a key differentiators for companies like BIGink today. Tomorrow’s differentiators may be any number of printing alternatives such as printed solar films and panels, printed displays, 3D prototypes, printed batteries, and even interactive paper with printed circuits.

There are certification programs for new construction, existing buildings, schools, “core and shell,” and commercial interiors.

What does that mean to printers like BIGink? LEED establishes standards for sustainable design; however, those standards don’t really give a lot of credit to sustainably sourced or manufactured substrates for graphics used for branded interiors, unless a large amount of those materials are used. Large amounts as in the construction or renovation of a large hotel or dozens of retail chain interiors.

Because the architects and designers who are seeking LEED certification are already considering building materials, they do understand the value of environmentally sensitive substrates. Scholl is taking advantage of that sensitivity to position BIGink as the supplier of choice for signage and branded interiors.

New substrates that are made of recycled content, are recyclable, or made of biodegradable plastics are now available. Then add water-based, aqueous inks or UV inks and VOC emissions are pretty much eliminated. The wallpapers that BIGink offers don’t contain any petroleum products and are hung with water-based adhesives.

Wallpaper, for example, is a part of the building itself, and with planning can be easily removed and recycled. By applying appropriate primers, the papers will release from the wall without damaging the wallboard underneath. When the papers are removed, they are sent back to the manufacturer who “up-cycles” them to make floor mats and soundproofing.

“Why is BIGink offering these products?” asks Scholl. “It’s the right thing to do – and our clients are demanding it. We have to have green solutions for them.”

When you stand back and consider how the physical structure – the building – is evolving into modular segments that can be removed, re-purposed and recycled, the opportunities for wide format printing are suddenly expanding. Printed panels can be clipped to walls or used as dividers. Now that it is possible to print with process color and white on glass and Plexiglas, even more architectural elements lend themselves to print.

BIGink, for example, is experimenting with “ferro paper” which is a lightweight magnet-receptive material with a smooth white paper finish. Because it will readily accept magnets of all kinds, signs can have re-positionable elements that eliminate the need to reprint or replace the sign when one small change needs to be made.

Furniture is big part of “branded interiors” especially in food and hospitality applications, and Scholl is working closely with a designer to create an “eternal” table top for restaurants and lounges. An image printed on a tabletop made of engineered wood can be sanded off and reprinted when it is damaged or to change a promotion.

To Scholl, a sign is no longer a sign; a wall is no longer a wall. It’s hard to tell where one ends and the other begins; that makes for a very exciting time to be a wide format printer. BIGink is the “back shop team member” for architects and designers. And the back shop is a great place to innovate and experiment; to help designers understand what can be done.

Print is not dead; it is changing. Images are no longer pasted on a surface, they are part of panels that can be adjusted, modified, moved, changed, and reused. Architects and designers have a strong aesthetic sense and are looking to communicate in a physical space; whether they are creating a branded interior or providing directions and instructions.

High quality, environmentally sensitive images and substrates are a key differentiators for companies like BIGink today. Tomorrow’s differentiators may be any number of printing alternatives such as printed solar films and panels, printed displays, 3D prototypes, printed batteries, and even interactive paper with printed circuits.