Who would have thought you could find a small printing company that runs seven presses and nine pieces of bindery equipment - most of which date from the 19th century - next to a polymer platemaker and a

Xerox DocuColor, circa the 21st century?

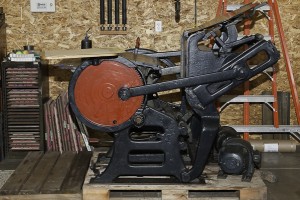

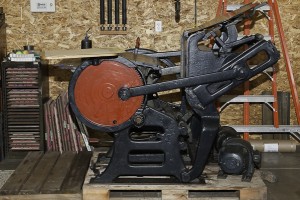

Somehow time got confused in this small Bellingham, Washington, print shop. The

DocuColor and a

Gordon Old Style Platen Press can indeed occupy the same space. And occasionally the proprietors of

Bison Bookbinding and Letterpress,

Carly James and

Kevin Nelson, even use the two on the same job!

While Ben Franklin and his contemporaries would have been comfortable with the Gordon, they would be hard pressed to figure out how to use "the big green button" on the Xerox.

Typical small job printers in the 1800s produced broadsides, pamphlets and an occasional small book. Fast-forward to Bison and what do you find on the tables ready for packaging and delivery? Broadsides, pamphlets and an occasional book; along with invitations, business cards, CD jewel case inserts, personalized photobooks, packaging, and labels.

Carly and Kevin (who are artists, musicians, designers, and bookbinders) see no contradiction at all. As a comfortable user of computer technology, Carly takes designs created digitally and turns them into polymer plates for printing on 130-year old equipment like the Gordon. It's a natural connection to supplement the old equipment with a color digital printer.

Living the Green Life

Bison Bookbinding opened in 2004 in a 1500 square foot space in Bellingham's business district and a couple of years later doubled to include gallery space. This past winter, Carly and Kevin began to search for a house with enough space to bring their operation home.

The urge to reduce their space requirements and to lighten their environmental impact even more sent them looking for just the right location. In a surprising twist of luck, they quickly found a location with a huge garage workspace (the previous owners had been welders and carpenters) and a house with a spacious, well-finished basement.

To top it off, the garage included a massive ceiling-mounted lift that made it easy to move the heavy presses into place.

Toward Zero Waste

Printing companies of all sizes practice sustainable production; there is a place for very small printers as well as very large printers. Appropriate to their size, Bison recycles 95% of their waste. It is also important to note that they have extremely low input requirements too. If you were to do a life cycle analysis of their operation, you'd have some of the "normal" elements missing.

- Power input: minimal

- Paper consumption: minimal

- Waste and emissions: minimal

Printers everywhere are trying to reduce makeready waste, but when your makeready is one sheet, how much better can you get? In truth, most of the products Bison prints are 6½" x 10" or smaller, so it really takes only 10 to 12 press sheets, or one full sheet, to bring the presses up to color and registration.

Harking back to the 1800s when output was often limited to 300 impressions a day, Bison has such small runs that shop management tools like

Franklin Estimating can't be applied; the numbers don't go

down far enough!

Carly, an expert bookbinder and maker of handmade paper, makes much of the paper used in their operation from cotton linters, though she does use other tree-free fibers such as hemp. Do they use recycled paper? The fibers that go into the paper are virgin, yet because she puts all trim back into new paper, they

are recycling.

Taking the "ink kitchen" down an order of magnitude in size, Kevin - a natural at color management - works out of his "ink kitchen cabinet" to match Pantone colors for printing. Most people expect a certain look from letterpress printing, however with skill and talent, it's theoretically possible to produce process color on a letterpress.

Living Their Values

"We approach everything like a piece of art, produced at a sustainable speed," says Carly. "We want to make something that people will save and cherish." There are companies who produce millions of photo books a year; Bison makes them one sheet of paper, one cover, one book at a time. The true value is in the craftsmanship that goes into each book.

Their customers are people who are artistically minded; who want something unique for themselves or to represent their businesses. As a result Bison takes on projects like a recent board book with metal covers.

"We just want to be a sustainable size that let's us be artists," Kevin adds, "and lets us run a business that supports us."

Living in a transitional community like Bellingham where a low-energy lifestyle is appropriate, Bison Bookbinding contributes to - and is supported - by

Sustainable Connections, an organization of business and community leaders who are working to build local economies based on sustainable practices.

Working where they live, printing on recycled and tree-free paper, using vegetable-based inks and recyclable plates, and printing on century-old equipment, Carly and Kevin clearly walk their talk. They share their knowledge and commitment, and they are proof that small can be profitable and sustainable.

Somehow time got confused in this small Bellingham, Washington, print shop. The DocuColor and a Gordon Old Style Platen Press can indeed occupy the same space. And occasionally the proprietors of Bison Bookbinding and Letterpress, Carly James and Kevin Nelson, even use the two on the same job!

While Ben Franklin and his contemporaries would have been comfortable with the Gordon, they would be hard pressed to figure out how to use "the big green button" on the Xerox.

Typical small job printers in the 1800s produced broadsides, pamphlets and an occasional small book. Fast-forward to Bison and what do you find on the tables ready for packaging and delivery? Broadsides, pamphlets and an occasional book; along with invitations, business cards, CD jewel case inserts, personalized photobooks, packaging, and labels.

Somehow time got confused in this small Bellingham, Washington, print shop. The DocuColor and a Gordon Old Style Platen Press can indeed occupy the same space. And occasionally the proprietors of Bison Bookbinding and Letterpress, Carly James and Kevin Nelson, even use the two on the same job!

While Ben Franklin and his contemporaries would have been comfortable with the Gordon, they would be hard pressed to figure out how to use "the big green button" on the Xerox.

Typical small job printers in the 1800s produced broadsides, pamphlets and an occasional small book. Fast-forward to Bison and what do you find on the tables ready for packaging and delivery? Broadsides, pamphlets and an occasional book; along with invitations, business cards, CD jewel case inserts, personalized photobooks, packaging, and labels.

Carly and Kevin (who are artists, musicians, designers, and bookbinders) see no contradiction at all. As a comfortable user of computer technology, Carly takes designs created digitally and turns them into polymer plates for printing on 130-year old equipment like the Gordon. It's a natural connection to supplement the old equipment with a color digital printer.

Living the Green Life

Bison Bookbinding opened in 2004 in a 1500 square foot space in Bellingham's business district and a couple of years later doubled to include gallery space. This past winter, Carly and Kevin began to search for a house with enough space to bring their operation home.

The urge to reduce their space requirements and to lighten their environmental impact even more sent them looking for just the right location. In a surprising twist of luck, they quickly found a location with a huge garage workspace (the previous owners had been welders and carpenters) and a house with a spacious, well-finished basement.

To top it off, the garage included a massive ceiling-mounted lift that made it easy to move the heavy presses into place.

Toward Zero Waste

Printing companies of all sizes practice sustainable production; there is a place for very small printers as well as very large printers. Appropriate to their size, Bison recycles 95% of their waste. It is also important to note that they have extremely low input requirements too. If you were to do a life cycle analysis of their operation, you'd have some of the "normal" elements missing.

Carly and Kevin (who are artists, musicians, designers, and bookbinders) see no contradiction at all. As a comfortable user of computer technology, Carly takes designs created digitally and turns them into polymer plates for printing on 130-year old equipment like the Gordon. It's a natural connection to supplement the old equipment with a color digital printer.

Living the Green Life

Bison Bookbinding opened in 2004 in a 1500 square foot space in Bellingham's business district and a couple of years later doubled to include gallery space. This past winter, Carly and Kevin began to search for a house with enough space to bring their operation home.

The urge to reduce their space requirements and to lighten their environmental impact even more sent them looking for just the right location. In a surprising twist of luck, they quickly found a location with a huge garage workspace (the previous owners had been welders and carpenters) and a house with a spacious, well-finished basement.

To top it off, the garage included a massive ceiling-mounted lift that made it easy to move the heavy presses into place.

Toward Zero Waste

Printing companies of all sizes practice sustainable production; there is a place for very small printers as well as very large printers. Appropriate to their size, Bison recycles 95% of their waste. It is also important to note that they have extremely low input requirements too. If you were to do a life cycle analysis of their operation, you'd have some of the "normal" elements missing.

Printers everywhere are trying to reduce makeready waste, but when your makeready is one sheet, how much better can you get? In truth, most of the products Bison prints are 6½" x 10" or smaller, so it really takes only 10 to 12 press sheets, or one full sheet, to bring the presses up to color and registration.

Harking back to the 1800s when output was often limited to 300 impressions a day, Bison has such small runs that shop management tools like Franklin Estimating can't be applied; the numbers don't go down far enough!

Carly, an expert bookbinder and maker of handmade paper, makes much of the paper used in their operation from cotton linters, though she does use other tree-free fibers such as hemp. Do they use recycled paper? The fibers that go into the paper are virgin, yet because she puts all trim back into new paper, they are recycling.

Printers everywhere are trying to reduce makeready waste, but when your makeready is one sheet, how much better can you get? In truth, most of the products Bison prints are 6½" x 10" or smaller, so it really takes only 10 to 12 press sheets, or one full sheet, to bring the presses up to color and registration.

Harking back to the 1800s when output was often limited to 300 impressions a day, Bison has such small runs that shop management tools like Franklin Estimating can't be applied; the numbers don't go down far enough!

Carly, an expert bookbinder and maker of handmade paper, makes much of the paper used in their operation from cotton linters, though she does use other tree-free fibers such as hemp. Do they use recycled paper? The fibers that go into the paper are virgin, yet because she puts all trim back into new paper, they are recycling.

Taking the "ink kitchen" down an order of magnitude in size, Kevin - a natural at color management - works out of his "ink kitchen cabinet" to match Pantone colors for printing. Most people expect a certain look from letterpress printing, however with skill and talent, it's theoretically possible to produce process color on a letterpress.

Living Their Values

"We approach everything like a piece of art, produced at a sustainable speed," says Carly. "We want to make something that people will save and cherish." There are companies who produce millions of photo books a year; Bison makes them one sheet of paper, one cover, one book at a time. The true value is in the craftsmanship that goes into each book.

Their customers are people who are artistically minded; who want something unique for themselves or to represent their businesses. As a result Bison takes on projects like a recent board book with metal covers.

"We just want to be a sustainable size that let's us be artists," Kevin adds, "and lets us run a business that supports us."

Living in a transitional community like Bellingham where a low-energy lifestyle is appropriate, Bison Bookbinding contributes to - and is supported - by Sustainable Connections, an organization of business and community leaders who are working to build local economies based on sustainable practices.

Working where they live, printing on recycled and tree-free paper, using vegetable-based inks and recyclable plates, and printing on century-old equipment, Carly and Kevin clearly walk their talk. They share their knowledge and commitment, and they are proof that small can be profitable and sustainable.

Taking the "ink kitchen" down an order of magnitude in size, Kevin - a natural at color management - works out of his "ink kitchen cabinet" to match Pantone colors for printing. Most people expect a certain look from letterpress printing, however with skill and talent, it's theoretically possible to produce process color on a letterpress.

Living Their Values

"We approach everything like a piece of art, produced at a sustainable speed," says Carly. "We want to make something that people will save and cherish." There are companies who produce millions of photo books a year; Bison makes them one sheet of paper, one cover, one book at a time. The true value is in the craftsmanship that goes into each book.

Their customers are people who are artistically minded; who want something unique for themselves or to represent their businesses. As a result Bison takes on projects like a recent board book with metal covers.

"We just want to be a sustainable size that let's us be artists," Kevin adds, "and lets us run a business that supports us."

Living in a transitional community like Bellingham where a low-energy lifestyle is appropriate, Bison Bookbinding contributes to - and is supported - by Sustainable Connections, an organization of business and community leaders who are working to build local economies based on sustainable practices.

Working where they live, printing on recycled and tree-free paper, using vegetable-based inks and recyclable plates, and printing on century-old equipment, Carly and Kevin clearly walk their talk. They share their knowledge and commitment, and they are proof that small can be profitable and sustainable.