It’s hard to believe Graph Expo is almost upon us! And July is already seeing announcements and disclosures from exhibitors who will be bringing new products and technologies to the show.

I recently had the opportunity to speak with Yariv Bustan, Product Manager at Scodix, who shared a very interesting new product announcement that I, in turn, wanted to share with you in this exclusive WhatTheyThink article.

I am sure our readers are familiar with the Scodix Ultra family of digital enhancement presses which offer post-print addition of variable density embossing and gloss to add interest and value to the printed sheet. And you may remember that the company brought to market the Scodix Rainbow, producing the Scodix Digital Glittering experience. More recently, Scodix introduced Scodix SPOT, a special polymer developed for use with the Scodix Ultra Pro digital enhancement press that digitally produces a silkscreen effect in a cost effective way for short runs

At Graph Expo 2015, Scodix will be unveiling yet another brand-new capability for its Ultra Pro presses: Digitized inline foil. While there are other digital foiling solutions available, Scodix claims that this is the only one to offer digitized foiling at production speeds and quality. As in the past, new customers can choose whether they want to add the foiling unit at purchase or later, or not at all. Existing Ultra Pro owners can upgrade to add the foiling unit.

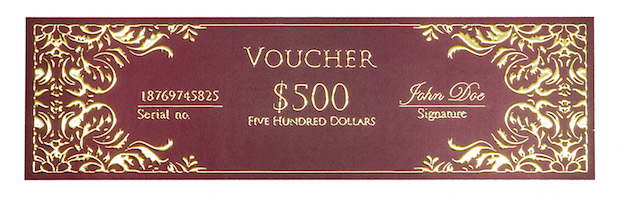

Examples

How It Works

This new application is based on a specialized polymer developed by Scodix – each Scodix application requires a different polymer and the Ultra Pro units can easily switch between polymers depending upon application needs.

The sheet(s) to be foiled are delivered to the press, where an image of the sheet is captured. The image of each sheet is used to calculate its exact registration for the foil application, since there might be slight variances from printed sheet to printed sheet due to the mechanics of printing or lamination or humidity, etc. The calculations are done using a dedicated sophisticated algorithm to ensure accuracy on each sheet. Scodix identifies this as another differentiator from other foiling solutions.

Areas to be foiled are determined by the foiling layer included in the incoming file and the polymer is applied to the areas to be foiled, which can include fine lines and small type as well as larger areas. The balance of the process is comprised of four steps:

- Activating the polymer so it will secure the high quality print and fine details

- Optimizing the polymer characters for best interaction with the foil and to enable the use of wide variety of foil types

- Applying the foil and peeling it off so foil only remains in target areas (large variety of industry standard foiling materials are used)

- Full curing of the foiled polymer to ensure high durability print, and ejection to the press delivery area.

While this all sounds complicated, and it is from a technology perspective, from a user perspective, it takes mere seconds, with the press delivering 1,200 B2+ finished sheets per hour. The operator simply inserts the sheets, presses print and in a matter of seconds the first sheet is available for delivery or further finishing.

“Our entire product line is focused on the high volume industrial environment,” Bustan said. “We have designed the press not just to create samples or mockups, but to work in mass production. If you create 1,000 pages with foil, at the end of the process you have 1,000 sellable sheets with foil. This new module enables high quality foiling in a very cost effective way for short to medium runs, something that cannot be done today. We have shown this capability to a few customers around the world, and the reception has been quite enthusiastic. We are excited to be unveiling it to a larger audience at Graph Expo, where we will be in Booth 2231.”