It’s a drupa year! You know what that means! Lots of new, exciting technologies being introduced in every equipment category, and binding and finishing is no exception. In What They Think’s August 16 webinar, “Technology Outlook: Finishing & Embellishment,” Kevin Abergel and Trish Witkowski provided a 50,000-foot look at the trends and technology introductions in the category.

For details and a full recounting of their coverage, view the entire webinar here.

So what’s hot?

1. Automation that removes human interaction.

Witkowski and Abergel noted that the innovations are coming fast and furious. “Everybody is automating,” says Witkowski, “and while this is a trend we’ve been watching for years, we were just talking about how each year has its different automation trends. Sometimes it’s speed and sometimes it’s workflow. This year, it feels like it's operator function—removing human interaction in any possible way we can.”

The result is a reduction in the need for a highly skilled, highly educated workforce, making it easier for printers to hire new workers without industry experience.

Witkowski and Abergel gave the example of the updated FlexCut 102 Digital Rotary Die Cutter System from B&R Moll. While not a new machine, it has some powerful updates that improve its function for less skilled workers. The machine is also now the first full-size B1 sheet in the rotary die cutter on the market.

“So they went from a 30 x 30 to a 30 x 40,” says Abergel. “Now they can run a full size B1 (28 x 40-in.) press sheet, digital or offset. They also have the ability to load pallets, so you get rid of that double handling, which is really cool. Plus, they’ve just added a lot of really good enhancements.”

Another standout in the automation category was the Stahl H2P folder that, in addition to many updates, has a new smart light system in which lights change color (blue, green, red) to alert operators to various production issues and alert them to where those issues are.

2. Explosion in new players.

A second trend is the explosion in new players coming into digital embellishment. “Usually, when you have more than one or two options to choose from, that’s a sign of something going mainstream,” Abergel observes. “Now you have six, seven, eight companies coming to market. Things are really heating up.”

As an example, the pair pointed to the new ZRX from Harris & Bruno. Yes, after 75 years, Harris & Bruno is getting into the digital market with its digital coater married to an anilox coater. “There's a big demand for uncoated materials,” says Abergel, “so they’re able to take that chamber anilox and put down barrier coatings on uncoated materials, then put varnish and foil on top so it doesn’t get absorbed in.”

The company is offering three new products:

- ZRX B1P (B1 Portrait)

- ZRX B2L (B2 Landscape)

- ZRX B2P (B2 Portrait)

All three flood coat, spot coat, and foil stamp in one single pass. They can also embellish directly on uncoated media without lamination. “We’re seeing brands push back against lamination these days,” says Abergel. “This gives you the same look, but without the plastic.”

For its part, JetFX is partnering with a wide variety of partners to offer effects such as digital spot coatings, digital screen, digital foil, digital casting holograms, micro embossing, and propriety ultra matte finish. This year, the company is making news by making the jump from web to sheetfed, launching A3 sheetfed and B1 machines next year.

“JETFX will also be supplying the inkjet engine for new KOMPAC embellishment press that will be coming out next year,” says Abergel.

KAMA is getting into the digital embellishment market with a B2/B1 machine ready at the beginning of the year. “After 130 years in business, KAMA has announced that it will enter the digital space with a new digital embellishment press called the Hammerhead, which was introduced at Drupa 2024,” says Witkowski. “The press will offer spot flat, spot tactile and digital foil with a max speed up to 5,700 B2 per hour.”

3. Bindery equipment designed to be robust and productive as a standalone, but also to integrate as part of a larger workflow.

Abergel gives the example of Duplo’s DuSense DDC-8000 B2 Raised Spot UV Coater, which can handle maximum press sheet sizes of 23 x 42-in. up to 600 gsm and offers an option to add cold foil inline. Holographic, metallic, and matte foils can be applied without lamination. The machine integrates with the company’s new DSM 1000 B2 Platen Die-Cutter, addressing the traditional integration challenges in raised varnish and embellishing. It also integrates with Duplo’s DC-746 B2 Slitter/Cutter/Creaser.

“These machines are really designed to play well together,” Abergel says.

Noting Duplo’s investment in the A3 market, Witkowski adds that Duplo’s investment in B2 equipment is a major statement that the company is ready to focus on industrial printing and commercial printing at a higher end.

4. Focus on anti-counterfeiting features.

Whether it’s RFID or holograms, more and more companies are introducing equipment with anti-counterfeiting features. Witkowski gave the example of Bobst, which introduced its NOVAFOIL 106 Hologram Hot Transfer Stamper designed to produce a wide variety of high-end security hologram applications. “It offers 10 modules that are basically plug and play,” she says. “This allows printers to offer lots of different applications for security and bank notes and so on. It’s just a really, really cool machine.”

Witkowski also notes NOVAFOIL’s AccuRegister system, which is critical for high-security applications.

5. Robots, cobots, and hybrid robots.

Witkowski particularly geeked out on the robotics category, loving that no longer are robotics for large businesses only. For example, the StackStar C Autonomous Stacking System from Heidelberg is designed for small and medium sized businesses. It can be set at different finishing machines, offers a wide range of formats, and offers reversibility of the system according to production flow.

“To me, it feels like the beginning of robotics for all versus robotics for just the really big, high-volume companies,” she says.

MBO’s CoBo-Stack 30i, which builds on the capability of its 10i, stands out in the robotics category for its safety features. It monitors a one and a half meter radius around the machine. When no human is detected in the zone, the robot operates at full industrial speed. If a human approaches, it automatically switches to a slower, collaborative mode. The CoBoStack 30i transports product stacks, such as folded signatures, from the delivery point to the table. The cobot then picks up stacks weighing less than 5 kg (11 lbs.) and places them on pallets, eliminating the need for manual lifting.

6. Higher levels of productivity.

No surprise—everything is getting faster and more productive. Take the Highcon Beam 3 + Beam Writer, which is 50% more productive than the company’s Beam 2. According to Highcon, the machine can handle 10 folding carton jobs of a thousand sheets per shift. Plus, by writing DART foil on the Beam Writer, printers can save average of 10 minutes set up time. “If you add it up, it frees up 16 hours of beam capacity for every 100 jobs,” says Witkowski.

Koenig Bauer is introducing more productive machines, as well. Its Cut Pro X 3SB high-speed rotary die cutter has a maximum speed of 1600 sheets per hour and can perform multiple enhancements to a carton in a single pass. It also claims the tightest sheet-to-sheet register in the industry because it uses the same transfer system as a sheetfed press. For packaging, it has introduced the Alias high-productivity folder gluer running at 600 meters per minute with super-fast makeready and tons of features.

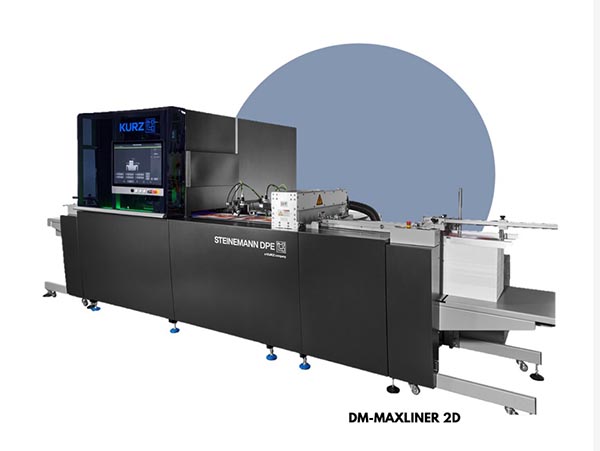

Kurz has introduced three separate digital embellishment technologies, including one, the DM-MAXLINER 2D, that is unique to the industry—an industrial sheetfed digital embellishment system for 2D digital metallization. The machine prints inkjet not on the sheet, but on the back of the foil, then cures it directly to the foil before laying the foil down and transferring it to the sheet.

“This allows them to create a flat foil look,” says Witkowski. “That's really, really hard to do with the other methods. They're able to do flat foil directly onto really tough materials like uncoated because the foil is already cured.”

New from MBO is its CC 23 Contour Cutter for its modular finishing system. It allows printers to do shape cuts, window knockouts, and lots of other types of finishes and perforations. Also new is its SC 23 Spot UV Coater with an integrated curing unit. “The neatest thing about the machine is that you can locate it anywhere in the rollfed finishing line,” says Abergel. “It can be optionally portable.”

A major emphasis for MBO is its AlphaJet, which integrates inkjet printing, embellishment, and predictive maintenance into a single B1 sheetfed production line. “What’s really cool is that this machine allows you to jet varnish designs and foil designs at the same time,” notes Abergel.

Other Innovations

Witkowski and Abergel sped through an array of other technology innovations that What They Think readers do not want to miss. Horizon, Horizon & Hunkeler, Kolbus, MGI, Müller Martini, Rollem, Scodix, and Technau…from high-speed entry-level saddle stitching to more options for embellishments on uncoated materials, you won’t want to miss a thing. So check out the full webinar with Witkowski and Abergel’s insights on the most important new introductions and features.