(Watch Ryan McAbee and Pat McGrew’s video interview with PrintFactory’s Simon Landau here.)

This article is sponsored by PrintFactory as part of WhatTheyThink’s Print Software Product Spotlight series. In preparing this article, the WhatTheyThink Print Software Section editors conducted original, in-depth research on PrintFactory’s workflow software. This Product Spotlight describes what the editors feel are the product’s strengths in the marketplace. PrintFactory reviewed the final article for accuracy but had no editorial control over the content.

Wide-format print production is changing. Customer requirements for color accuracy, print quality, and turnaround times are becoming more demanding. For compliance and efficiency, many organizations and brands require reports for color accuracy and the ability to track and trace jobs. The experience level and preferences of print buyers are also changing with generational turnover who prefer self-service and automation to make their jobs easier. These challenges increase when overlaid with the persistent complexities of print production. Some of the print production challenges include:

- Difficulty receiving “good” files from clients in a reasonable timeframe.

- Dealing with complex orders with multiple job parts that require an interplay between several departments.

- Spending too much time in prepress to manually preflight, create layouts, cut files, and edit the native file to print several rounds of test prints to dial in color for jobs.

- Dealing with multiple RIPs.

- Wasting hours tracking down where jobs are on the production floor.

Solving these challenges requires a modern workflow for wide-format print production that extends beyond the raster image processor (RIP) basics and includes smart color, workflow, and job management functionality. PrintFactory empowers wide-format printing workflows with its renowned support for thousands of devices and easy-to-implement color management capabilities. It continues to expand its ecosystem to include desktop and cloud-based software with features that improve your customer’s experience and make the printing company more efficient.

Take Back Control Over Color Consistency and Ink Savings

Managing color across multiple printing technologies, device manufacturers, RIPs, ink sets, and substrates is challenging for the most technology-forward print companies that have color experts on staff. Print Factory’s software makes intelligent color management decisions so operators who are not color experts can make accurate color profiles for multiple printers at once, taking minutes for each using a two-step process. The result is a DeviceLink ICC color profile unique to that printer, substrate, ink set, and manufacturer. Since the process is straightforward and takes minutes, the process can be repeated to control color output across your fleet of printers enabling the ability to shift production from printer-to-printer while ensuring consistent and repeatable output. Knowing print can be reliably output across your fleet also means time and material savings by eliminating multiple proof prints or reprints based on color rejections.

PrintFactory also allows you to reduce the total ink consumption to achieve the same consistent and sellable print output, resulting in a 20-30% savings in ink costs. The ECOSAVE software feature uses expert color optimization techniques to improve grey balance and neutrals while improving fine detail in highlight and shadow areas.

Optimize the Rest of the Workflow

From the time your customer places an order until it is delivered, there are four primary stages on the production floor: job onboarding, prep, optimization, and output. Whether your customer chooses to upload a file to PrintFactory Cloud or submit the work through an API, XML, or hotfolder connection, there are many entry points to onboard jobs and start automation based on the requirements of each client.

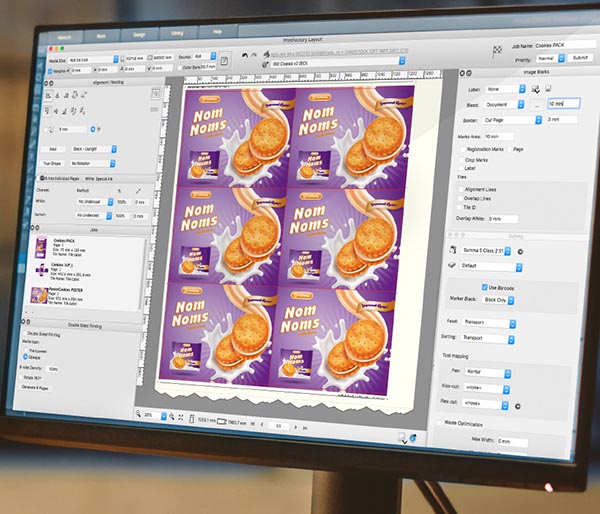

The quality of customer-submitted files varies wildly, so printing companies must convert and standardize them for output. PrintFactory can create unlimited customer or application-specific workflows where files are automatically preflighted, routed, and processed based on the required changes. When files need exception handling or extra attention, prepress operators can use PrintFactory’s Editor to quickly fix issues related to fonts, bleeds, marks, colors, and adding variable data. Layout works in a similar way, where operators use the Layout tool to create non-standard, complex layouts that can be reused as templates for the next time the job is produced.

While ECOSAVE provides ink savings and substrate optimization, the JIT Dynamic Nesting Cloud offers intelligent nesting or combining multiple files from the same job or multiple jobs. Printers can use barcodes to track each job and job part throughout the production process. As jobs are added to production buckets, PrintFactory analyzes every job to find work that can be batched or combined into a single nested job. Jobs with similar production requirements and deadlines are nested, enabling smart scheduling of resources.

For printing companies using wide-format equipment from multiple vendors and multiple RIPs, the output stage is a manual process due to siloed print islands. PrintFactory connects to over 4,000 output devices and provides a centralized solution to track and manage jobs upstream so equipment operators can focus solely on running the machine to get the best results. Using a single technology provider for the workflow ensures consistency in color and processed output versus multiple RIP technologies. Production managers can also view operational and color quality reports to make proactive decisions through a single dashboard.

From Shop to Factory

The days of using multiple workflow and RIP vendors within wide-format print production are over. Today’s growth drivers are found in building a better customer experience, reducing the time from order to print output, and ensuring color and quality control throughout the entire process. It is time to move from a print shop mentality to a software-enabled and people-powered print factory obsessed with automation and efficiency.

Visit PrintFactory at PRINTING United this September 10–12 in Las Vegas, Nevada, for insights and in-person demonstrations.