C.P. Bourg Inc. Debuts 4-Up Bourg Sheet Preparation Module (BPM) at DSCOOP Edge 2019

Press release from the issuing company

- The NEW C.P. Bourg product is immediately available in multiple configurations and connected to many popular brands of sheet fed digital cut sheet printers or presses.

- Designed specifically to automate perfect bound book and stitched booklet manufacturing processes that require a wide range of formats and sizes.

Orlando Fla. – The C.P. Bourg Preparation Module (BPM) is an industry first, innovative print finishing product designed for commercial and in-plant print production facilities. The BPM is a sheet converting system that allows print professionals to automatically divide large “parent” sized printed sheets into intermediate, form sized or final sized sheets in-line at process speed between their printer / press and C.P. Bourg finisher. This automated solution dramatically reduces page imaging costs by allowing users to print multiple pages of a document on less expensive large sheets and eliminating the inefficient and expensive manual labor used to hand process those large sheets into small usable sizes on a guillotine cutter prior to finishing. This revolutionary device automates the traditional Perfect Binding and Booklet Making workflows by significantly decreasing manufacturing time and costs. The BPM Module can function with two (2) up or four (4) up page production workflows and is scalable so If the desired output isn’t achievable using a single Preparation Module, a second BPM may be docked in-line with the first. This expandability feature allows the user to deploy multiple additional functions on the second unit for greater flexibility in manufacturing.

Options for these additional functions include:

Bleed Trimming – two independently adjustable slitting wheels that can remove up to 100mm or 4” of material from the head and foot of the sheet as it passes through the paper path

Creasing – a stepper motor driven scoring cylinder creases the center of each sheet for downstream folding accuracy and precision, eliminating toner cracking or flaking and greatly reducing fold pillowing.

Chop Cutting – A rotary cutter divides the passing sheet in half creating two equal sized sheets for finishing

Buckle folding – An Automated fold plate allows a single sheet to be folded in half

Sheet ejection – Unnecessary or excess sheets may be discarded into a reject tray prior to finishing.

In-Line, Off-Line, Dual Mode, JDF and Bi-Directional Operation

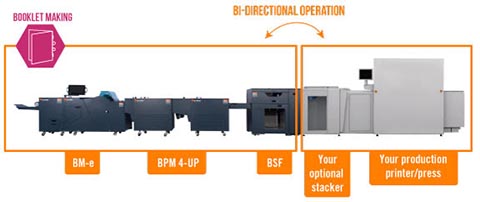

The BPM has been designed to be implemented in one of three operational modes. In-line, docked between the printer and desired finisher. Off-line, docked between the Bourg Sheet Feeder (BSF) and desired finisher or in Dual Mode, docked in-line with the printer and Bourg Sheet Feeder allowing the system to operate either in-line or off-line depending on job details. The BPM is JDF compliant allowing users to configure the product functions precisely as they require. Each unit has the ability to operate bi-directionally as either a “Left to Right” or “Right to Left” paper path direction and will support production toner, ink jet or liquid Electro Ink print engines from multiple manufacturers.

"Productivity is the key requirement in production finishing today,” said James Tressler, Vice President of Sales, C.P. Bourg Inc. “The BPM sets a new standard in finishing workflow automation. Our users are eliminating costly procedures and wasteful touch points in their manufacturing processes which, in turn, is making them more profitable and competitive in the market.”

- KYOCERA NIXKA INKJET SYSTEMS (KNIS) INTRODUCES BELHARRA, THE NEW WAVE OF PHOTO PRINTERS

- New RISO Printing Unit Offers Easy Integration for Package Printing

- March 2024 Inkjet Installation Roundup

- Inkjet Integrator Profiles: Integrity Industrial Inkjet

- Revisiting the Samba printhead

- 2024 Inkjet Shopping Guide for Folding Carton Presses

- The Future of AI In Packaging

- Inkjet Integrator Profiles: DJM

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free