Koenig & Bauer Continues Strong Leadership Position In Folding Carton Market

Press release from the issuing company

Technology-driven advances set high performance standards for fast-growing segment

- Printers increasingly eye expanding folding carton market to broaden their base

- Ultra-fast makereadies, cold foil, and double coaters are particularly attractive for folding carton makers in medium and large format presses

- QualityPass allows folding carton printers to provide extensive reports on the quality and consistency produced

When leading folding carton printers from 41-inch to 64-inch format size seek to find the best solutions for their customers, where do they turn? The market leader in providing the fastest, most technologically-laden presses for advanced folding carton applications is Koenig & Bauer, which is consistently rated for its high quality solidly-built manufacturing process, superior service, and enhanced solutions for the complex needs of folding carton customers.

“As the world market leader in the manufacture of folding carton printing presses, we have kept our fingers firmly on the pulse of the ever changing market and maintained this position by offering the highest quality presses and services while partnering with some of the most high-profile leading folding carton printers,” Chris Travis, director of technology at Koenig & Bauer (US/CA) states. “Printers are charged with the mandate to light up store shelves with sophisticated, colorful folding cartons; our goal is to help them deliver those products, not just with the press but with the process as well.”

In today’s competitive market, folding carton printers need to quickly respond to the unrelenting demands of their consumer-facing customers in the diverse fields of pharmaceutical, food, beverage, cosmetic, spirit, and other segments. Speed, precision, and service are required to maintain a positive customer experience. Store shelves are brimming with a wide variety of containers that require eye-catching point-of-sale shelf appeal. Brands are asking folding carton printers to design custom crafted award winning packaging for their products that also protect against counterfeit packaging. Speed to market is essential in an ever-changing, fast-paced environment in which print quality and consistency needs to be at the forefront as well as special print services such as coating applications, finishing, embossing and other enhancement methods.

“One of many reasons that folding carton printers continue to invest in additional new Koenig & Bauer presses whether medium or large format is our ability to uniquely configure the press for their needs,” says Travis. “We’re seeing a resurgence in double coaters to provide those necessary special effects all inline in one pass. Cold foil is continuing its momentum as a superior special effect especially for folding carton printers. As for features, simultaneous processes for fast-paced print operations and PMS colors that are automatically controlled and reported upon are nearly always ordered. Plus we receive many questions and requests for applications for our custom-built VariDry low-energy curing system.”

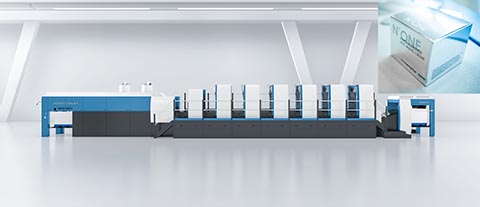

Folding carton manufacturers are finding that a key trend is to perform ultra-fast makereadies for shorter run, seasonal boxes and to successfully compete against digital printing carton production. Koenig & Bauer has the solution. Its Rapida 106 has been the undisputed makeready world champion in medium format since 2008. Not only that, its production speeds up to 20,000 sheets/h prove it is the fastest press in its format class. Due to a raft of unique automation solutions, such as the sidelay-free infeed, quick job changes and smooth handling on the Rapida 106 provide the speed needed by folding carton printers. Logistic systems ensure continual throughput and complete inline color control along with simultaneous process allow folding carton producers to be more competitive than ever. Expensive waiting time is transformed into efficient production time. Alongside consistent implementation of the revolutionary DriveTronic dedicated drive concept, it is quality management which here plays a decisive role. With inspection options, which even include inline PDF comparisons, the Rapida 106 is yet again the technology leader in the field.

Curtis Packaging, a renowned Connecticut printer known as a luxurious packaging provider, recently partnered with Koenig & Bauer to manufacture and install a new custom-built Rapida 106 11-color double coater press, the only one of its kind in the world and specially designed by Curtis management. Its high-end folding carton customers represent some of the world’s most well-known brands for cosmetics, liquor, health and beauty, confectioneries, biomedical and sporting goods. This key press, which was built for one pass efficiency and unique capabilities for short-run fast changeover jobs, includes 10 printing units, a coater, an additional printing unit and coater. The first two printing units are cold foil capable. Curtis is experiencing significant improvement in makeready times and higher run speeds for total faster throughput.

With more PMS colors on a folding carton, printers need to have quality and color control systems to reduce variability. Koenig & Bauer is leading the way with its newest Version 8 of its popular and unique QualityPass software for sheetfed presses. This dynamic product provides extensive reports on the quality and consistency of print produced and provides a score as a percentage against the required fields of the ISO 12647-2 standard such as CIE LAB values, dot gain (TVI) and trapping. The trend reporting function allows printers to be able to demonstrate color consistency throughout their folding carton production run via reports produced at the end of the job by the software and provides great reassurance for the printers’ customers. QualityPass reports are generated as a PDF for every job produced and contain every measurement taken by either the ErgoTronic Color Control device for inline color density measurement or the QualiTronic ColorControl inline system. The viewer of the report can analyze the quality of print produced and make the required adjustments to improve the scoring, for example; tensioning blankets or making alterations to the plate output curves.

“Last year, every press installed in North America was configured with an inline color control system,” says Travis. “That’s how important it is. Our folding carton customers tell us how essential it is for them to quantify their data and be able to give a detailed report to their brand customers.”

Not only is quality and color control necessary for folding carton printers to provide tight color control with minimum variation but productivity and efficiency. Koenig & Bauer has developed systems for folding carton printers to alleviate these areas as well. With an increased use of colors being used on folding cartons and more versions due to the increasingly individual cartons being printed, printers require speedy automated roller wash-up systems to help maximize efficiency from job to job and quickly wash colors up and move on to the next job. Koenig & Bauer’s DriveTronic SRW (Simultaneous Roller Wash) provides increased productivity and is a huge time saver by having the ability to wash the rollers while producing as well as providing high color quality and consistency. Folding carton press operators appreciate its fully automatic plate changing in which all plates are changed in incredible fast times without any human intervention.

Wausau Container Corporation, a prominent Wisconsin folding carton manufacturer, noted that Koenig & Bauer built a special size of Rapida 105 PRO that competitors couldn’t match. "It is a special larger maximum sheet size and larger maximum image size than is normal for a standard Rapida 105 PRO press-a Koenig & Bauer exclusive,” says Chuck Plier, president of Wausau Container Corporation. “It is providing us with greater throughput, better print quality, and has the ability to provide precise press documentation to support our customers. Its inline inspection system captures each and every sheet, even while running at top speeds, and ensures that the job matches what the customer has sent to us. It provides us with a high level of reporting for credibility that we can share with our clients."

Many folding carton manufacturers are tasked with meeting a wide range of needs from their brand customers. This includes multi-color printing in a single pass using a variety of coating applications on different substrates along with specialty effects such as embossing, foil, and other techniques. As e-commerce continues to grow, folding cartons play an important role in delivering a positive end-user experience as well as protecting the product within. Brands are placing increased emphasis on these effective packaging tools.

“What distinguishes Koenig & Bauer from any other press manufacturer is our resolve to guide our folding carton customers into profitable solutions with our sophisticated technology,” says Travis. “As the world leader in large format presses, we’ve built the finest reputation for producing unique offset presses in all format sizes that provide value-added, tailored solutions to their business. We understand that the folding carton market is fast moving and competitive---that’s why we continue to monitor trends in the industry and keep abreast of what our customers will need in the future.”

Koenig & Bauer (US) is located in Dallas, Texas and a member of the Koenig & Bauer Group, which was established 200 years ago in Würzburg, Germany. Koenig & Bauer’s claim, “We’re on it.” gets to the heart of Koenig & Bauer’s values and competencies for all target groups. The group's product range is the broadest in the industry; its portfolio includes sheetfed offset presses in all format classes, post press die cutting, folder gluers, inkjet presses and systems, flexographic presses, commercial and newspaper web presses, corrugated presses, special presses for banknotes, securities, metal-decorating, glass and plastic decorating. For more information visit the company's web site at www.koenig-bauer.com.

The industry-leading Koenig & Bauer Rapida 145 is one of the flagship presses for folding carton manufacturers.

- Real World AI for the Printing Industry

- Harnessing the Power of Synergy: HP High Speed Inkjet and Indigo Liquid Toner Technologies

- KYOCERA NIXKA INKJET SYSTEMS (KNIS) INTRODUCES BELHARRA, THE NEW WAVE OF PHOTO PRINTERS

- New RISO Printing Unit Offers Easy Integration for Package Printing

- March 2024 Inkjet Installation Roundup

- Inkjet Integrator Profiles: Integrity Industrial Inkjet

- Revisiting the Samba printhead

- 2024 Inkjet Shopping Guide for Folding Carton Presses

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free