As we sweat through this summer’s “heat dome,” when events all over the country are being canceled due to excessive heat and cities are breaking multiple all-time heat records, we are reminded of our appreciation for modern air conditioning. We not only appreciate it, but we are dependent upon it—and it’s all thanks to what happened at one printing company determined to save its business in 1902.

The advent of air conditioning, often hailed as one of the most transformative technological advancements of the 20th century, started out as a way to address the printing challenges resulting from the hot, unrelentingly humid air on printing shop floors, including the one at Sackett & Wilhelms Lithographing & Publishing Company in Brooklyn, N.Y., at the turn of the 20th century.

Carrier’s first set of mechanical drawings designed to solve a production problem at the Sackett & Wilhelms Lithography & Printing Company in Brooklyn, New York. Image source: Carrier.

“It’s Hot in Here!”

Can you imagine working on a printing shop floor (or anywhere, really) without air conditioning? Especially in the early years, these facilities were often cramped, poorly ventilated, and subject to the whims of the weather. In summer, high temperatures made working conditions unbearable. However, beyond worker comfort, the environmental conditions posed significant challenges to the printing process itself.

These days, when air conditioning is the default in every commercial building, we might forget just how challenging temperature and humidity fluctuations used to be. High humidity can cause paper to absorb moisture, leading to warping and misalignment during printing. Ink, too, can be profoundly affected, thickening or thinning depending on the temperature, leading to inconsistent print quality. These issues often resulted in wasted materials, increased costs, and delayed production schedules.

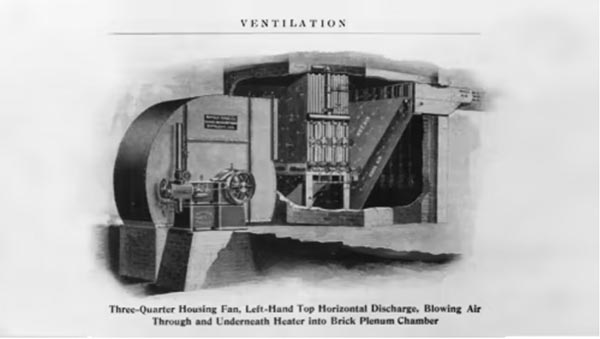

In response to these challenges, early printing shops experimented with various methods to control their environments. These included using ice to cool the air, installing fans for better ventilation, and even employing rudimentary humidifiers. While these methods provided some relief, they were far from perfect solutions.

Early Cooling Methods Before Modern Air Conditioning

Before the invention of modern air conditioning, cooling methods were rudimentary at best. Ice, harvested in winter months and stored in ice houses, was a common means of cooling air. Fans and ventilation systems were also used to circulate air and provide some measure of relief from the heat. However, these methods were inadequate for maintaining the precise conditions required in industrial settings like printing shops.

The breakthrough came in 1902 when Willis Carrier, a young engineer working for the Buffalo Forge Company, was tasked with solving a problem at Sackett-Wilhelms, which like its peers was struggling with fluctuating temperature and humidity levels that compromised print quality. After two summers of extreme heat disrupted business and nearly ruined Sackett-Wilhelms’ business, the company reached out to Buffalo Forge, which put Carrier on the job.

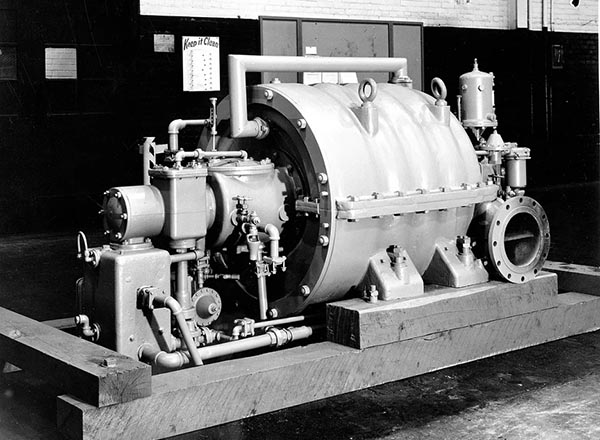

No, it’s not a steam engine. It’s the first “modern” air conditioning unit installed in 1902. Image credit: Smithsonian Institution.

Carrier’s solution was the world’s first modern air conditioning system. It used a combination of cooling coils, fans, and ducts to regulate the temperature and humidity in the printing shop.

The first set of coils was installed at the Sackett & Wilhelms plant late in the summer of 1902 along with fans, ducts, heaters, perforated steam pipes for humidification, and temperature controls. Cooling water was drawn from an artesian well that first summer and supplemented by an ammonia compressor in the spring of 1903 to meet the demands of the first full summer of operation. This system of chilled coils was designed to maintain a constant humidity of 55 percent year-round and have the equivalent cooling effect of melting 108,000 pounds of ice per day. (Source)

This invention not only solved the immediate problems faced by Sackett-Wilhelms, but it also set the stage for the widespread adoption of air conditioning in various industrial applications.

We Have Printing to Thank for It!

Willis Carrier’s invention has had far-reaching implications beyond printing. It has revolutionized industrial processes, improved working conditions, and even transformed living environments. Today, while air conditioning is ubiquitous, its relationship to the printing industry has all but been forgotten.

We in the printing industry can keep its memory alive. Lest we forget, all we have to do is look at one of our in-home window air conditioning units or the name plates on the outside of the air handling units of industrial systems and notice the name, Carrier Engineering, a company that Willis Carrier started after the success of his new invention.

Stay cool, everyone!

Discussion

By Mark Vruno on Jun 27, 2024

SWEAT SHOPS: This is sad but true, Heidi! I remember, years ago, speaking to a sweaty press operator in a printing plant about indoor factory temps that exceeded 100 degrees F. He said, "They don't put A/C in here for us. The temperature and humidity controls are for the machines and computers! They [management] are protecting their investments!!" That's the way it was. Can you imagine? Thank goodness, times change.

Discussion

Only verified members can comment.