Brian Kavanagh and his partner, Denise DeCarolis, opened SkinDip’t (Bel Air, Md.) in 2019. The decision to get into the cannabinoid (CBD) wellness market came after Denise struggled to find skin care that wouldn’t react with her skin and Kavanagh had a bout with back surgery that drove him to find an alternative to the traditional heavy medications prescribed for pain.

Their passion for the industry borne out of their own experiences, the pair developed two all-natural skin care lines—one with CBD and the other without—and a variety of CBD health and wellness products, such as gummies for sleep, anxiety, pain management, and more.

Skin Dip’t CBD health and wellness shop in Bel Air, MD.

Skin Dip’t carries the Skin Dip’t non-CBD skin care line, the PharmEssence (CBD) skin care line, and the shop brand of CBD gummies, as well as a variety of CBD products from other manufacturers. Of the CBD and non-CBD products carried by the shop, 10%-15% are their own.

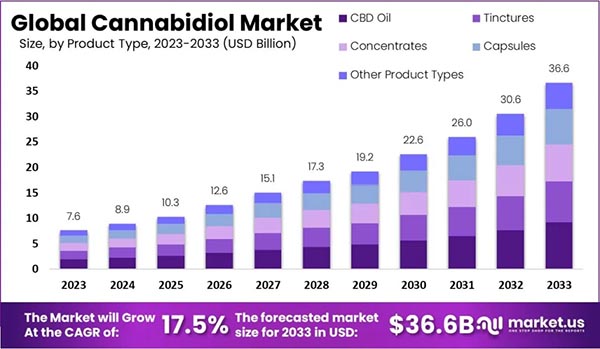

Can Anyone Say 17% CAGR?

CBD is a market printers need to pay attention to. The global CBD market reached $7.6 billion in 2023 and is projected to surge to approximately $36.6 billion by 2033. That’s a remarkable CAGR of 17.5% during 2024-2033. This market can include medical and recreational marijuana dispensaries, as well as health and wellness shops like Kavanagh’s.

Although Maryland legalized marijuana in July 2023, Kavanagh’s products actually use hemp, not marijuana. Even now, the highest level of THC (which also a type of cannabinoid) in any of its products .3%, which is enough to provide health benefits but not enough to cause mind alteration.

For his shop, located on right off Main Street in Bel Air, Kavanagh purchases the ingredients for his products, manufactures them, and does his own bottling and labeling. A listen to his labeling process gives insight into one of the challenges faced by similar shops in this market. He is certainly not alone.

Labeling…One at a Time

Skin Dip’t purchases labels from two different sources: an online label company used for plain label stock Kavanagh uses to print non-specialty labels in-house; and a label house that pre-prints and ships vinyl labels required for products that contain oils.

Brian Kavanagh, vice president of Skin Dip’t

Vinyl labels are used for all Skin Dip’t skin care products, such as skin and eye creams, and are delivered in 3-in. rolls. These labels can take up to one month to arrive (sometimes longer).

Paper labels come in sheets, which Kavanagh uses to print certain labels on demand with a desktop laser printer. These labels are adhered to products such as lip balm and zippered packets of CBD gummies that do not require oil-resistant labels.

The process is flexible and inexpensive…until you consider Kavanagh’s time. (He spends five to seven hours per month printing and applying labels.) Furthermore, colors will often not match run to run, and sometimes colors will fade.

Why Not Pre-Print?

Why doesn’t Kavanagh simply purchase all of his labels pre-printed to minimize the time and maintain color consistency?

“I keep changing the container, playing with the formula, and adding new ingredients,” he says. “To have them pre-printed, I need to purchase 500 at a time. Because I’m always changing things, I don’t want to get stuck with 500 labels that I can’t use anymore.”

Retail display of Skin Dip’t’s house brand products.

There are other challenges that have, in Kavanagh’s experience, limited his label purchase options, as well:

- Finding labels in the right sizes to fit the vials he uses.

- Finding substrates with the same color options for all of the sizes of labels that he needs.

- Proper adhesion of paper labels to vials.

- Need to purchase quantities smaller than 500.

Some labels Kavanagh applies using a desktop label machine (the lip balm, for example, is labeled 50-100 at a time). Others, particularly those being applied to non-standard-sized vials, he applies by hand. If the labels don’t adhere, he will often overlay them with clear tape. To the customer’s eye, the labels appear to be laminated. But professional looking or not, Kavanagh knows how time-consuming that workaround can be.

Skin Dip’t lip balm for which labels are printed and adhered in-house.

Using this manual method, Kavanagh is, however, able to produce custom labels for popular products like lip balm. “It’s really popular to do custom labels for children’s birthday parties,” he explains. “I’ll put the birthday girl’s name on them.”

It’s a Workable System…For How Long?

It’s a flexible and workable system…for now. But growth of the shop’s own product lines is challenged and his margins are impacted by the manual packaging and labeling process.

While the paper-based labels are “cheap” in terms of materials, when you take into consideration the time, it’s another matter altogether. What could be done in that time? Development of new formulations? PR and marketing? Developing strategic relationships for co-branding?

CBD products are an exploding market, but for the small independent retail shop, growth comes with its own dilemmas. The efficiency of packaging and labeling is one of them, and it's a dilemma that Skin Dip’t doesn’t experience alone. Just ask your local CBD shop!

Discussion

Only verified members can comment.