We sat down with Robert Barbera, Director of Production Solutions Marketing in Canon USA’s Business Information Communications Group Division, and talked about Canon’s commitment to production print—in all its forms.

WhatTheyThink: Canon has become the market leader in production inkjet and has obviously invested heavily in inkjet, but not at the expense of toner-based machines. What is Canon’s toner strategy and what are some of the trends you have been seeing in the electrophotography market?

Robert Barbera: As you noted, Canon continues to invest in developing new toner and inkjet presses and the workflow solutions to help improve productivity and grow print applications.

Robert Barbera: As you noted, Canon continues to invest in developing new toner and inkjet presses and the workflow solutions to help improve productivity and grow print applications.

The imagePRESS is the key to our successful production color toner business. Last year, we launched our new imagePRESS V family of products with the imagePRESS V1000, and at PRINTING United 2022, we showcased the imagePRESS V900 Series and announced the high-end imagePRESS V1350. So this is a whole new family of imagePRESS color digital presses. The imagePRESS V1000 is a new mid-range solution with a clean-sheet design that expanded our offerings. The imagePRESS V900 Series replaced our very popular imagePRESS C910 Series. At the high end, the imagePRESS V1350 replaced our imagePRESS C10010VP Series and provides customers faster print speeds and the ability to print on heavier weight media.

We see a strong demand for our production toner presses and we continue to elevate the capabilities to help customers improve their productivity and grow the range of applications they can offer. A lot of advancements in the imagePRESS V family are around automation, image quality and color control. The entire imagePRESS V family has inline spectrophotometers that with PRISMAsync or the Fiery—automate color calibration process” media calibration and color profiling proces. As you know, finding skilled operators is becoming more and more challenging. Having the ability to automate and simplify the engine color calibration, G7 calibration and profiling are major time savings that any operator can easily execute. The person operating the imagePRESS V family with PRISMAsync print server can start the automated color tasks, and within a few minutes the process will be complete without any operator intervention.

The imagePRESS V family also has a Sensing Unit option which streamlines and automates the media optimization and color uniformity before the press run, and quality control during the press run with closed-loop control of the color and registration..

It is great to hear feedback from our customers on the positive impact that new imagePRESS V family and automated color controls is having on their business.

WTT: Do you find that custmers need to diversify and expand the products they offer, and how does the imagePRESS V family help them accomplish that?

RB: Yes, customers are always looking for new print applications they can offer to help grow their business. We run a social media campaign called “Impress with imagePRESS” that highlights different high value applications that can be printed with imagePRESS. We are constantly exploring ways we can expand the range and sizes of media that can be printed to help increase application capabilities that customers can achieve with these products. For example, the imagePRESS V1000 introduced the capability to run magnetic media. Both the V900 and the V1000 have the capability to run envelopes of various sizes. To help run synthetic media, we recently introduced a static eliminator designed to reduce static buildup that is sometimes found when running synthetics. And the imagePRESS V1350 runs up to 450 gsm, allowing customers to print packaging applications.

One of our first imagePRESS V1350 customers in the U.S. is Choice Marketing. Their primary applications is printing sports trading cards which requires precision for front to back registration and color quality on heavy weight media. They’re ecstatic about the capability, repeatability and the quality coming off imagePRESS V1350 on the heavy weight media. You can hear what they have to say on the video case study at Choice Marketing Case Study (https://www.youtube.com/watch?v=VRKdf18ktcA).

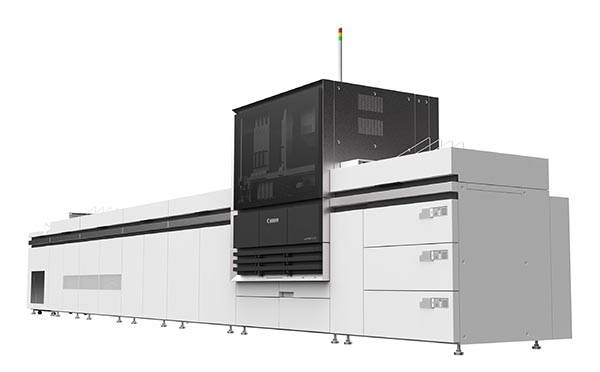

imagePRESS V1350

WTT: As we talk, we just returned from PRINTING United, where Canon had announced two new entries in its production inkjet portfolio—the varioPRINT iX1700 and the LabelStream LS2000. Where do they fit into Canon’s general inkjet portfolio?

RB: At the same time as PRINTING United in Atlanta, Canon held the Canon Expo event in Japan, which is a very important strategic event for the company that showcases some of the current and future technologies. At this year’s event, Canon unveiled two new inkjet presses. The first is the varioPRINT iX1700, which is a high-quality cut-sheet inkjet production press running at speeds up to 165 letter pages per minute. They also showcased the LabelStream LS2000, which is a roll-to-roll digital inkjet label press. Both presses share some newly developed Canon inkjet technologies, such as brand new Canon printheads with a resolution of 2400 by 1200 dpi that are designed to deliver very high quality and fine detail. They also feature newly developed aqueous-based pigment inks—so the heads, the head cleaning and the ink circulation are common to both units. The LabelStream has an additional white ink for label film applications. The two products were shown at the Canon Expo in Japan, and we had presentations around them at PRINTING United.

The varioPRINT iX1700 fits a gap in the marketplace between the current high volume/high quality production inkjet presses and high speed toner presses. When I talk with commercial printers and inplants they are investigating inkjet for their operation, but some don’t have the current print volumes to justify one of the current high volume/high quality presses.

The varioPRINT iX1700 has been designed to bring high quality inkjet to the larger audience in the marketplace—commercial printers, in-plants, direct mailers, and digital printers, with a price and position between our imagePRESS V1350 and the varioPRINT iX3200 series.

varioPRINT iX1700

WTT: When are they expected to ship?

RB: The general availability is early 2025. We’ll start some early customer installs in the U.S. in the second half of 2024.

WTT: So to switch gears now and talk about PRISMA. How has PRISMA evolved?

RB: PRISMA solutions have a long heritage with over 30 years of innovations and offerings, and as a result, PRISMA can mean different things to different people. Customers using our cut sheet production print presses may know PRISMAsync, which is our print server that drives our varioPRINT and imagePRESS devices. The high volume direct mail and transactional customers know PRISMAproduction, which is a workflow solution for Canon’s high-speed inkjet continuous-feed and sheetfed presses.

Canon has been constantly developing and expanding the PRISMA offerings and the PRISMA brand, and there are currently over 20 PRISMA offerings. So PRISMA has become a broad portfolio of Canon developed workflow solutions, applications and print servers for production and large-format customers.

Overtime, PRISMA has grown to be much larger than a specific product, but it has shaped into a broad portfolio that is tailored to specific customer business requirements. A good example of its value can be seen in our large-format business. Canon recently launched the PRISMA XL Suite, which is a combination of PRISMA tools to support wide-format printing. One of those tools is PRISMAelevate XL, which helps create tactile, textured dimensional printing on the Arizona where you’re building up the layers of ink to create that tactile effect.

So whether you’re a small print shop or a large print factory there are specific PRISMA applications tailored to empower your printing capabilities.

WTT: You’ve also moved PRISMA to the cloud.

RB: Yes, we have recently launched a range of new PRISMA cloud-based applications and a platform called PRISMA Home. Developing PRISMA Home is a key part of our cloud strategy. PRISMA Home provides customers one portal to access and manage their supported PRISMA cloud-based applications and tools. Through PRISMA Home customers can easily administer their internal users, connect the different printers to specific applications and share their cloud storage across the various applications.

So the key part of our strategy was building this platform’s infrastructure. And now, we’re starting to bring out more applications and expand the supported devices to a broader range of Canon and non-Canon printers.

WTT: Such as?

RB: We have five different applications that customers can now access through PRISMA Home. Some of these applications are provided as a value added applications to help support the customers’ business insight and production.

For example, we just introduced PRISMAlytics Dashboard v2.0 which provides a “pulse” of the printer performance and utilization. For instance, what’s each printers uptime/utilization? When are they running? When are they not running? When was maintenance being performed? When was calibration performed? How many color pages or mono pages were printed? How much of each media or toner/ink was used?

Users can very easily compare performance over any period of time and view the graphical results from all supported/connected printers. They can also download the information for their own reporting. And the new version of PRISMAlytics Dashboard now supports the full Canon production portfolio including imagePRESS with PRISMAsync or Fiery, varioPRINT, Canon’s inkjet production presses and imagePROGRAF devices.

PRISMA Dashboard

WTT: There is also PRISMAcolor Manager, which we recently ran a Product Spotlight on?

RB: PRISMAcolor Manager is another application in PRISMA Home that allows customers to efficiently validate their color output against standards (industry or their internal standards) and report and track the results over time. PRISMAcolor Manager is an open solution that provides colorvalidation workflows that support Canon and non-Canon printers and presses.

WTT: Aside from things like automation and the difficulty of finding employees—the top challenges of recent years—are there any other general industry trends you’ve been seeing emerge that are starting to become important to your customers and to printers in general?

RB: Obviously attracting and retaining people is the biggest challenge for our industry. I would also say that customers—in-plants, commercial printers—are looking for new business ideas. What new types of applications can they produce? What are high-value applications? That’s what we’ve been showcasing with our print application samples to highlight a range of high value print applications. Our goal is to help stimulate ideas and creativity with customers of what can be achieved on the imagePRESS with different media types and sizes, embellishment or inline finishing.

What you also see is the changing dynamics of the industry. If you went into a commercial printer 15 years ago, maybe70% of their work might have been offset and 30% was digital. Today, it might be 40% offset, 40% digital, and 20% wide format. Their business mix has changed. With the increased diversification of their business they are looking to optimize their organization and processes to manage the work, quality and color across these different devices.

How do they achieve that consistent color across a digital press, an offset press, and a wide-format printer? Industry standards like G7 becomes very, very important here. Educating customers around G7 capabilities and how to easily implement it is becoming more and more important.

WTT: What’s next on the horizon for Canon?

RB: I have been at Canon for 11 years and it has been incredible to see the commitment to commercial printing markets through the various production and large format products we introduced over that time. We have become the market leader for digital production printing and there is much more on the way.

As I noted, we recently announced the varioPRINT iX1700 production inkjet and LabelStream LS2000. We are looking forward to bringing these exciting new products to market.

It is really an exciting time to be at Canon and to witness how our products and solutions are helping customers better serve their clients.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free