[sôf(t) landiNG, säf(t) landiNG]

soft landing (noun) · soft landings (plural noun)

- a controlled landing of a spacecraft during which no serious damage is incurred.

- in economics, a cyclical slowdown in economic growth that avoids recession. A soft landing is the goal of a central bank when it seeks to raise interest rates just enough to stop an economy from overheating and experiencing high inflation, without causing a severe downturn.

We noted last month in our annual review of printing, packaging, and related industry transactional activity that the past 12 months were characterized by a dip in the number of deals announced. This was the case in almost every category that we track, except for modest upticks in commercial printing, specialty products, and supplies distribution. (See The Target Report Annual Review: 2023 M&A Activity.) Nonetheless, within the context that overall deal activity has cooled off from prior years, there is still a steady cadence of deals across all sectors, some of which will be transformative to our industry over the long term.

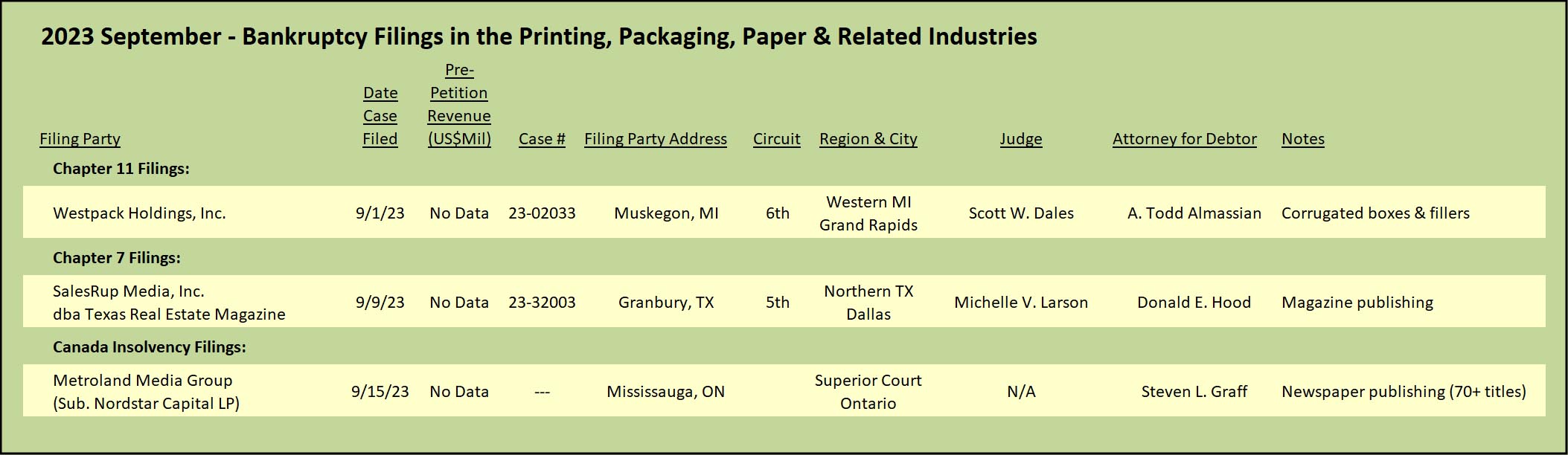

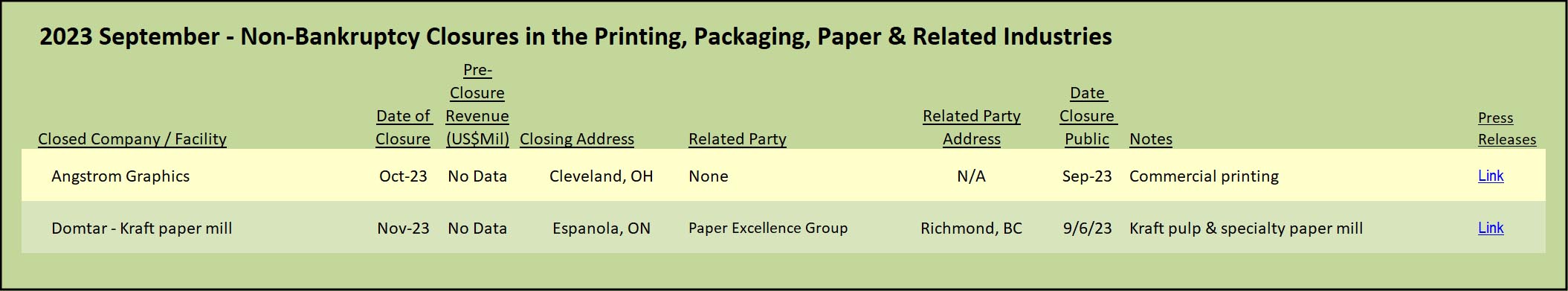

The classic signs of turbulence ahead have been in abeyance. Tuck-in transactions, in which the seller’s plant is closed and the business moved to the buyer’s production facility, were at or near historic lows. There were fewer bankruptcy filings in our industry this past year than in any year since we began The Target Report 12 years ago. The number of non-bankruptcy plant closures increased slightly, but remained close to the low point we recorded in 2022. As of this writing, the US economy, and our industry along with it, has avoided the hard landing that many predicted as the government largess ran out and interest rates increased.

Lest we be too sanguine about the certainty of a soft landing, we must note that in conversations with owners over the past six months, some tell us that the landing from COVID has not been smooth. Customers have begun to re-assert pricing pressure now that last year’s supply chain issues have mostly been sorted out and paper is generally available as needed. Lenders are more watchful and loan defaults have increased. Wages are increasing. Instead of a crash landing, we see a long tail of minor bumps and dips as the impact of the COVID pandemic and subsequent excesses is worked out over time. That is the view through the windshield, at least in the absence of a surprise event that might trigger a precipitous drop. Keep your seatbelts on, just in case.

Paper Manufacturing

After a couple weeks of rumors that a deal was afoot, Smurfit Kappa, based in Dublin, Ireland, announced a merger with US-based WestRock. When completed, the new company, to be named Smurfit WestRock, will have revenue of $34 billion and adjusted EBITDA of $5.5 billion. Despite being the smaller of the two, Smurfit shareholders will hold a majority of the combined shares and Smurfit senior management will lead the company which will be headquartered in Dublin. The North and South American operations will remain based in Atlanta, Georgia. The merger brings together two integrated paper producers with paper mills, packaging plants, and forestry operations.

WestRock itself is the result of the consolidation of the paper industry in the US, with origins dating back to 1846. Along the way, the operations of the Mead Paper Company and RockTenn were brought into the fold, among other acquisitions. (See The Target Report: The End of the Line for MeadWestvaco – January 2015.)

Smurfit Kappa was established as a box-maker in Ireland in 1934. In 1998, Smurfit merged with Chicago-based Stone Container, after which the company was acquired by private equity firm Madison Dearborn Partners. Subsequently, the company merged with Kappa Packaging and then returned to the public markets in 2007. The pending deal with WestRock will create the largest publicly held global paper and packaging business. The new entity will be a global fiber-based business operating in 42 countries, with 67 mills, approximately 500 converting operations, and 100,000 employees.

Paper Distribution

Paper distribution is also in transition. Clayton, Dubilier & Rice (CD&R), one of the granddaddies of private equity, recently announced that it had entered into a definitive agreement to acquire Veritiv. With revenue in 2022 of $7.1 billion, Veritiv looms large in the supply chain for many printing and packaging companies. In just the corrugated segment alone, in 2022 Veritiv distributed hundreds of millions of boxes that represented more than 4 billion square feet of corrugated material and more than 400,000 tons of kraft paper. In the fine printing papers segment, Veritiv sold and delivered more than 485,000 pallets of paper. In an indication of confidence in its ability to maintain profitable control over the paper supply chain, CD&R is paying a 31% premium over Veritiv’s 30-day trailing average share price.

Paper Mills Closing

The shuttering of paper mills continues unabated. Domtar, a division of the Paper Excellence Group, announced that it is indefinitely shutting down operations at its pulp and paper operations at its Espanola milllocated on the Spanish River in Ontario, Canada. The mill had been up for sale in anticipation by Domtar that it would be required to divest certain mills in order to gain approval from the Canadian Competition Bureau to purchase Resolute Forest Products. While Domtar was not required to sell this particular mill, and the deal with Resolute closed earlier this year, no buyer for the Espanola Mill has been found to date.

Citing years of high costs and ongoing operating losses, Domtar is mothballing the pulp and papermaking operations at Espanola. The closure will take approximately 280,000 tons of softwood kraft pulp and 69,000 tons of specialty papers out of the supply chain. According to Domtar, the pulp from the Espanola mill is used to manufacture tissue and towel products, but more importantly to our readers, the pulp from Espanola is well-suited for and also used for medical packaging, coated and uncoated specialty products, printing and writing paper grades.

The closure of the Domtar Espanola mill follows right on the heels of WestRock’s announcement in August that it is permanently ceasing operations at its paper mill in Tacoma, Washington. This closure took 510,000 tons of kraft and white top liner and bleached pulp production capacity out of the market. WestRock noted high operating costs and the need for significant capital investment as factors in its decision to close the mill.

Six days before the WestRock announcement to close the Tacoma mill, UPM Communication Papers announced its plan to permanently close its paper mill in Plattling, Germany. The closure of the Plattling mill will result in a reduction from the market of 380,000 tons of uncoated publication paper and 215,000 tons of coated publication paper. UPM cited the need to align its graphic paper capacity with a profitable level of customer demand.

Landing the Paper Airplane

The recent merger of Smurfit Kappa with WestRock, the move of Veritiv to a private equity platform, and the closures of paper and pulp mills are just the latest in a long string of transactions that are transforming the amount and type of paper supply to the printing and packaging industries. (See The Target Report: Paper Industry in Transition – May 2022.)

As with the larger economic picture, it appears that the paper market has managed a soft landing. However, the recent transactions and plant closures suggest that the consolidation and rationalization of production capacity will produce some turbulence along the way.

View The Target Report online, complete with deal logs and source links for September 2023

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free