This article is sponsored by Canon as part of WhatTheyThink’s Print Software Product Spotlight series. In preparing this article, the WhatTheyThink Print Software Section editors conducted original, in-depth research on Canon’s PRISMA Tools product. This Product Spotlight describes what the editors feel are the product’s strengths in the marketplace. Canon reviewed the final article for accuracy but had no editorial control over the content.

(Register here for the special WhatTheyThink Webinar “Color Management with Canon PRISMAcolor Manager” featuring David Zwang and Canon Senior Color Analyst John Thorburn.)

Canon’s PRISMA offerings include a wide range of applications and tools to help optimize print production workflows and digital printing production. These solutions have amassed over the life of PRISMA and have adapted to the changes in technology and production requirements, as their use requirements have changed significantly over the years.

The solutions have evolved from the requirement to support a single device and corresponding workflow with one DFE, to a need for automated workflows across disparate devices with constantly changing requirements.

It should be noted that, as the industry contracts, print service providers are taking on a broader range of applications in an effort to generate new revenue streams. In many cases, this results in an overlap between what might have been distinct and different markets, ranging from transactional print to direct mail, commercial print, packaging, and industrial applications.

Ultimately, savvy print service providers will seek workflow solutions that can adapt quickly to adequately address requirements across most or all of these segments, as they are not likely to want disparate workflow solutions within a single plant or multi-site operation.

Moving to the Cloud

Many of these solutions address an important part of any service provider’s infrastructure: the way in which work enters the plant. However, once you get the work into the plant, what happens next?

While many hardware manufacturers envision systems that support supply chain and production automation, the solutions tend to be weighted toward using their own products in an end-to-end solution.

Though this may work for some print providers, the mix platforms of many print providers with various established workflows will require more open solutions that can be integrated into their current workflow and processes.

This is why process modularity has to be a component of process integration.

The good news is that the data formats used today, in almost all cases, are open and structured. They can be translated and mapped to most systems and processes usually through APIs (Application Programming Interfaces). These open data formats include XML, JSON, and JDF/JMF, along with an assortment of image and special purpose formats.

By connecting these disparate systems in the cloud and mapping their respective data streams, you can drive production files and instructions downstream into press and finishing to automate the process.

Conversely you can extract data from many of these press and finishing systems and send them upstream to collect performance information. With the right software modules, you can monitor your equipment for predictive maintenance or other key performance indicators (KPIs).

This data has significant value and will become increasingly more important in the future.

In addition to improving and automating processes, you can also use this captured downstream and upstream data for longer term machine learning. Cloud-based data is really the life blood of machine learning, and machine learning is what will ultimately help pave the way to supply chain automation.

PRISMA Home

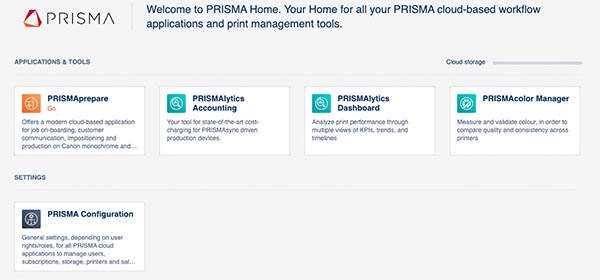

Canon’s PRISMA Home is the heart of the portal of PRISMA cloud applications connecting users to the current and future cloud-based offerings. PRISMA Home provides customers with one central access to the supported PRISMA cloud workflow applications and tools.

These tools currently fall into the categories of Color Management, Device Management, and Data Analytics, ultimately providing the data needed to help maximize the performance of your print devices, including monitoring, analysis, and cost allocation.

PRISMA Home

PRISMAcolor Manager

One of the recent additions to PRISMA Home is the award-winning PRISMAcolor Manager, a PRINTING United Alliance 2022 Pinnacle Product Award winner for Software, Color Management, and QC.

This enables operators to analyze color performance across Canon and non-Canon CMYK printers, by measuring and validating printed colors to help users compare quality and consistency. It verifies color conformance against industry or shop standards and presents overviews and trends at a glance, making key data actionable.

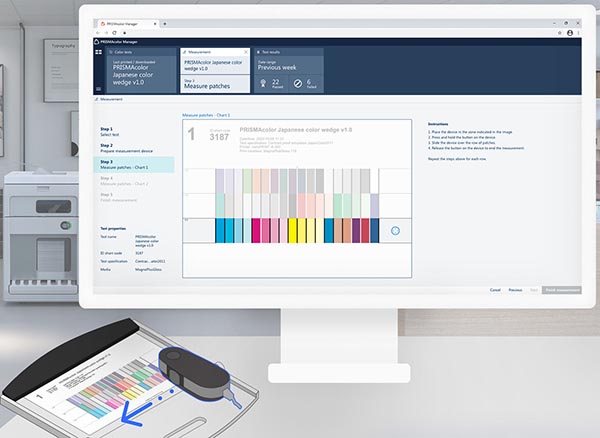

PRISMAcolor Manager was designed for non-expert and expert color operators alike. PRISMAcolor Manager uses step-by-step on-screen animations to guide users through the color measurement tasks. It has a flexible user interface, including tiles with drag and filter functionalities, so users can customize views to see precisely the information they need with the aim of helping to reduce errors and wasteful misprints. PRISMAcolor supports multiple color validation submission methods since, in any production environment, there can be a variety of DFE and printers.

Since the system is designed to support many different DFE’s and press configurations, there are four different workflows for doing color validation supported by PRISMAcolor Manager.

Reading the target with a spectrophotometer

Direct Print–Workflow

The Direct Print validation workflow is for Canon PRISMAsync and imagePRESS Print Server (Fiery) supported printers and brings some clever automation into how PRISMAcolor Manager sends the color charts and printer settings to them.

The benefit is that it can reach into the server’s color management settings for those registered servers, and set the print settings properly for when the user prints the chart. This can be really important, since it usually takes a more skilled operator to set the correct source profile and rendering intent.

Direct Print is triggered from the cloud and pushes the color chart onto a recognized server. The color chart in the Direct Print method uses the PRISMAcolor Control Wedge, which can be used to validate against the industry standard conditions, or your own.

With the PRISMAcolor Manager Control Wedge chart, the patches are reformatted and larger, so they’re easier to measure by hand with a spectrophotometer. All the user has to do is find the controller in the PRISMAcolor Manager cloud server and press “print” to get a printed result that’s set to the proper printing conditions and ready for validation.

PRISMAsync Import–Workflow

This workflow is specifically designed for a PRISMAsync server configuration. In this case, the validation is initiated and carried out from the PRISMAsync server. Since the server has embedded color capabilities, the operator can initiate internal color calibration and color validation tests.

Every model in Canon’s current line of V-series imagePRESS includes a high-quality inline spectrophotometer (ILS). These imagePRESS devices can perform completely automated color measurements and calibrations. With one button, PRISMAsync print server offers Automated Color Tasks, which can initiate press linearization, G7 calibration, device characterization, including the option of a custom media profile with G7 calibration. It measures the target on the printed press sheet, gives your result and applies needed corrections to the press setup.

The imagePRESS presses that include supported versions of the PRISMAsync print server with its embedded color capabilities, can also initiate color validation tests internally, the results of which can be automatically uploaded to PRISMAcolor Manager for tracking.

Download and Print–Workflow

This process starts by downloading a PDF file of an ID coded test chart from PRISMAcolor Manager to manually print on compatible CMYK printer that is SNMP enabled. PRISMAcolor Manager will then guide the operator through a step-by-step manual measurement process with either a compatible hand-held or chart-reading instrument. This provides the flexibility to validate disparate vendor print systems.

External Control Strip–Workflow

When the user has an existing workflow with an official control strip that is printed with each job, they can also validate with PRISMAcolor Manager.

The process starts by measuring an existing non-coded test chart with PRISMAcolor Manager in order to validate its color. This supports any brand CMYK engine that is SNMP enabled. This method also supports other types of test charts that can be added to PRISMAcolor Manager.

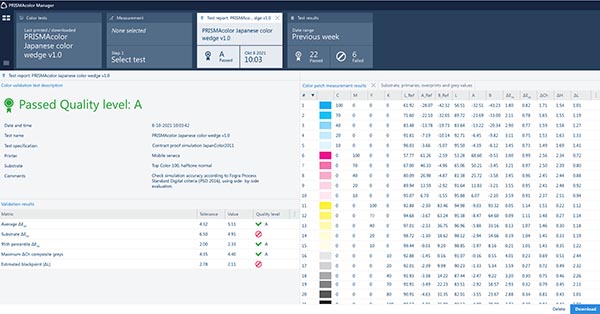

PRISMAcolor Manager validates color conformance with easy-to-understand overviews, and you can quickly see the graded results of color measurements against recognized international standards such as GRACoL2013, FOGRA 51, Japan Color2011, or your own defined targets and tolerances, in clear measurement charts and test reports.

With the online interface, you can easily analyze and compare validation results of a single or multiple printers in the plant. Operators and color specialists can zoom in for more detailed analysis of a specific printer, color metric or time period.

Make Ready vs. Color Control

To be clear, PRISMAcolor Manager color validation can be considered as a part of press color makeready procedures. PRISMAcolor Manager should not be confused with Canon’s inline automated press color control.

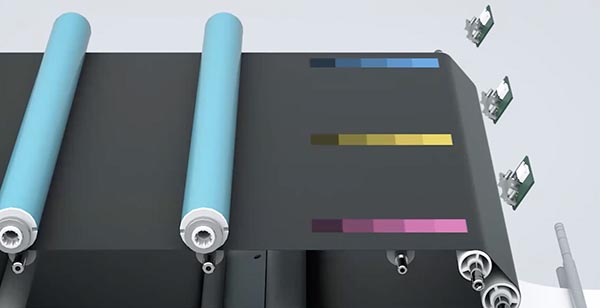

Canon imagePRESS models have been validating in-run color for years. In fact, an optional module called the imagePRESS Sensing Unit extends the range of in-run color control even further.

For example, the imagePRESS V1000 performs in-run color control through a number of automated technologies. The Multi-Density adjustment technology in-press system automatically measures 20 color patches (20,40,60,80,100) every minute, or 101 pages with built-in densitometers. The CMY patches are measured directly on the transfer belt and K on the drum, all without any operator involvement. If it reads outside of tolerance, the press adjusts in real time.

Densitometer check

The optional imagePRESS sensing unit module (if purchased) will capture a second measurement after the printed sheet has been stabilized through the fusing process. These sensing unit measurements are user configurable and can be taken on every printed sheet (space permitting) without slowing down press output.

Color accuracy and tone control can both be adjusted using imagePRESS ILS (Inline Spectrophotometer) technology. This built-in system, which consists of multiple spectrophotometers across the engine width, does an engine linearization upon operator initiation. It can also do G7 calibration, media profile creation, and color verification and validation, whether you have the PRISMAsync or and imagePRESS Server powered by Fiery. It automatically prints all the necessary color patches and measures them.

PRISMAcolor Manager can initiate color validation tests from the cloud and measure the printed test charts locally with a USB-connected X-Rite i1Pro or i1iSiS series instrument. However, when the DFE is recognizable to PRISMAcolor Manager, as is the case with Fiery and PRISMAsync systems, PRISMAcolor Manager can submit the required test charts directly to the DFE, automatically configuring the proper color validation print settings on the fly in real time.

In the special case of the PRISMAsync DFE, it can create a link to PRISMAcolor Manager such that color validation tests initiated and measured at the press go up into the cloud automatically for integration with all other validation test results, for tracking and trend analysis. PRISMAsync operators can choose which method they prefer.

PRISMAcolor Manager supports standard color control targets from Idealliance and FOGRA. With the PRISMAsync internal embedded color profiler, G7 calibrating and color profiling papers is a simple, unified, fast and automated color event.

In any case, regardless of your press, front end or what industry-standard control strip you’re measuring, it can all go in the PRISMAcolor Manager cloud, providing a central repository for color performance and validation.

PRISMAcolor Manager is one component of a long-term strategy that Canon has been developing to bring many of its PRISMA branded workflow applications and tools to the cloud. As each is introduced, they can be found in PRISMA Home.

Since process optimization and quality is critical to a print service provider’s success, Canon will continue developing solutions that focus on ease of use, print quality, consistency and business optimization.

Historic validation readings and average

PRISMAcolor Manager is a subscription based offering and some items references require separate subscriptions and purchases. See www.cusa.canon.com for solution requirements and specifications.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free