It was the smell that offended. It assaulted your senses. It emanated from the far end of the prep department, in the back, behind the large horizontal camera, by the plate exposure frames. This was not the sweet, almost floral, scent of the isopropyl alcohol evaporating from the fountain solution on the multi-unit offset presses. This was not the pungent, thick, smell of offset inks, nor was this the overwhelming petrochemical odor of the press wash at the end of the day when multiple presses shut down simultaneously.

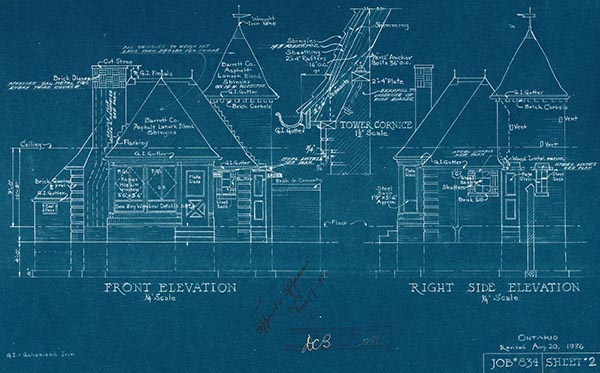

It was the ammonia that stunk. The smell permeated the prepress (né stripping) department in the early morning when the majority of blueline proofs were made. After exposure and processing, the blueprint paper was washed and laid out to dry, flat, but still never really flat. The strippers glued the bluelines back-to-back to emulate two-sided printing, cut, folded, and stapled the thick, bulky, crinkly blueprint paper to approximate the finished project as closely as possible. The sales reps, myself included, eagerly waited for production to sign off, so we could get on the road to take the blueprint proofs on our daily runs to customers. By the time the proofs were delivered, the smell had mostly lifted and our customers were spared the stench of ammonia-based blueline proofing.

Not long after I began my career in printing, substitute photosensitive papers that did not require obnoxious chemical processing came into widespread use as the proofing paper of choice for offset printers. The nasty ammonia smell was a thing of the past, an early olfactory benefit of the march of technology in our industry.

Reprographers

Traditionally known as blueprinting companies, reprographers are specialized firms that serve the architectural, engineering, and construction management (AEC) industries. Reprographers were called upon to produce copies of architectural and technical drawings. Often times, many sets of multi-sheet copies were needed for all the team members and crews involved in a construction project. As changes were made, new sets were required and rushed to the field. Minimal time elapsed and speedy delivery of the blueprint sets to the field crews was critical. As a result, reprographers often had multiple locations, distributed close to the customers, with delivery service included.

Reprographers were some of the earliest adopters of fully digital workflows, transitioning from analog prints using light and chemicals to wide-format xerographic toner-based devices. Plans and technical drawings are primarily monochrome, well-suited to early black-only xerographic devices. However, the seeds of many reprographers’ decline were planted in that initial transition to digital, as the need for printed copies by AEC customers was greatly reduced by increased electronic transmission and viewing of digitized technical drawings.

For some reprographers, the familiarity with wide-format monochrome printing devices and digital workflows became the foundation upon which to build a more robust business that offered a wide variety of services to a diverse client base. It was a small leap from the digital production of technical drawings to more generalized digital color wide-format printing.

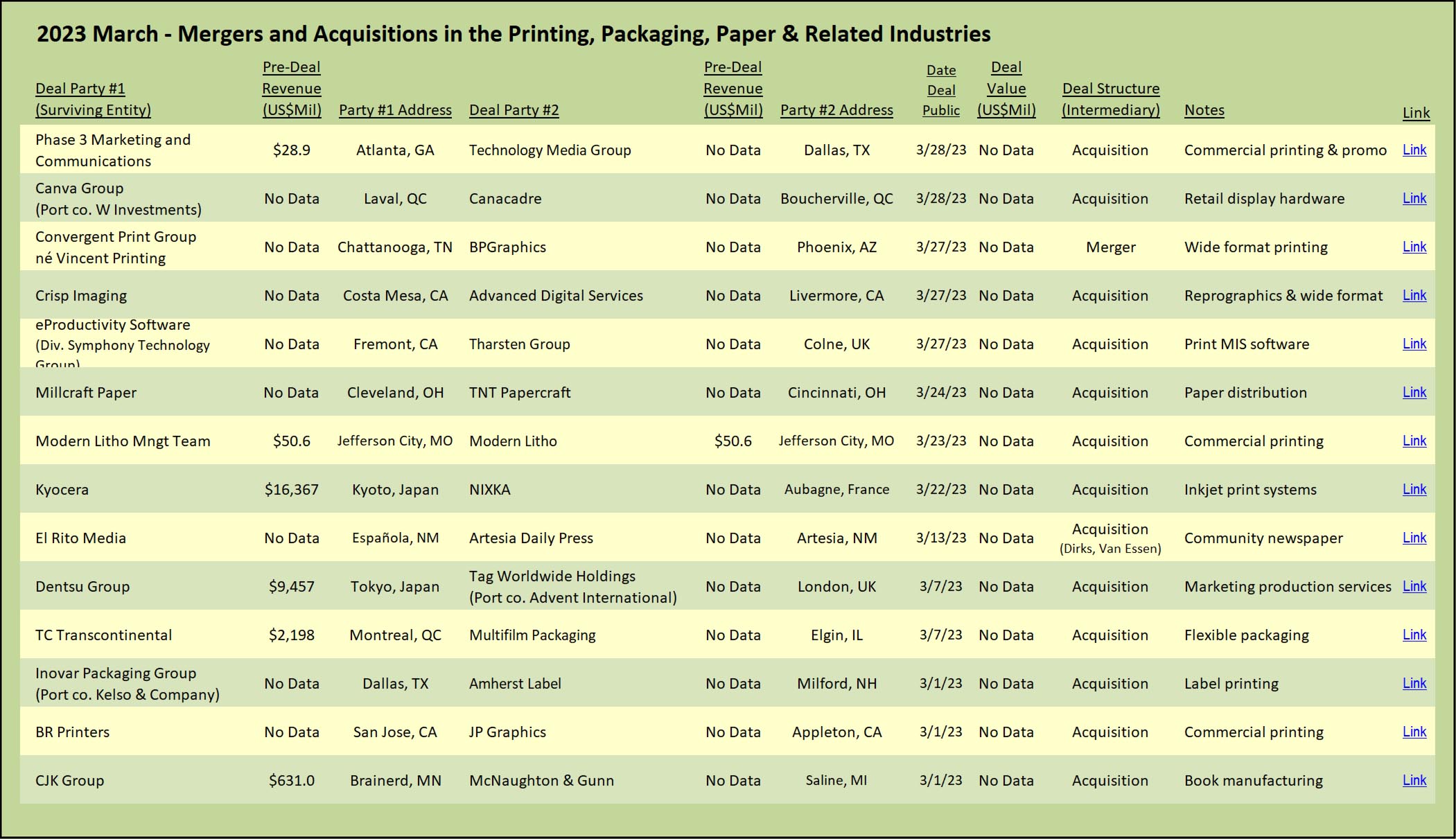

Crisp Imaging in California acquired Advanced Digital Services, the latest in a long list of acquisitions completed by the company. Crisp is an exemplar of the convergence theory in the printing industry: the integration of various printing technologies, digitally connected, enabling print companies to offer a more comprehensive range of services and solutions. Crisp Imaging added five acquisitions in 2022 alone, with a total of eight companies purchased since 2021.

Crisp Imaging was founded in 2001 as a franchise copy shop, but soon thereafter the founders realized that there was a need to serve the AEC market in southern California and they transitioned their shop to an independent company focused on reprographic services. As the needs of the AEC market shifted from printed to digital documents, Crisp expanded its gamut of services to include banners, office wall graphics, tradeshow displays, vinyl lettering, floor graphics, and installation, among other services.

The company still offers wide-format black-and-white prints on bond and vellum papers, Mylar prints, copy services, document scanning; all delivered via a company fleet in true reprographer style. The reprographic corporate DNA also runs deep in the company’s geographic strategy: many locations close to customers, now with twenty-one locations from Seattle to San Diego.

The Blueprint

The blueprint was one of the earliest methods of reproduction that relied on a photochemical reaction. Invented in 1842 by Sir John Herschel, the blueprint process enabled rapid and accurate reproduction of an unlimited number of copies. By the 1890s, the process had virtually eliminated the expense of lithographic reproduction of architectural and technical drawings and was far less costly and much faster to produce than a hand-traced reproduction.

Originally named the cyanotype, the process is based on a photosensitive paper that has been impregnated with ammonium ferric citrate and then developed with potassium ferricyanide. A negative of the desired image, most often a line drawing on translucent paper, was placed over the treated paper, usually held in place by a sheet of glass in a frame. In Herschel’s time, the necessary exposure to ultraviolet light was obtained by placing the frame outside for a couple minutes under bright sun, or up to ten minutes on a cloudy day. The light-sensitive coating is thereby converted to a blue dye, which is then chemically stabilized. The non-exposed areas are washed away, leaving the white of the paper.

Herschel made numerous contributions to the photographic methods of reproduction and is credited with coining the term photography in 1839. He discovered the process of fixing a photograph, which he applied to his first glass-plate photograph from 1839, and since it was fixed, the photo still exists. (Those of us in the printing business pre-imagesetters and film processors will remember the final stage of producing negatives for offset printing, swishing negatives back and forth in a tray of chemical fixer). Herschel was the first to apply the terms negative and positive to photography, terms which we still use today. He was an early experimenter with concepts of color photography.

Herschel made numerous contributions to the photographic methods of reproduction and is credited with coining the term photography in 1839. He discovered the process of fixing a photograph, which he applied to his first glass-plate photograph from 1839, and since it was fixed, the photo still exists. (Those of us in the printing business pre-imagesetters and film processors will remember the final stage of producing negatives for offset printing, swishing negatives back and forth in a tray of chemical fixer). Herschel was the first to apply the terms negative and positive to photography, terms which we still use today. He was an early experimenter with concepts of color photography.

As amazing as were his contributions to printing and photography, these were but side interests for Sir Herschel. He originated the use of the Julian day system in astronomy, named seven moons of Saturn and four moons of Uranus, the seventh planet which had been discovered by his father, Sir William Herschel. He contributed to the philosophy of science, wrote several articles for the Encyclopedia Britannica, and was three times the president of the Royal Astronomical Society. He built his own 20-foot reflecting telescope, which he took to South Africa with his family to study the southern skies, and also discovered four galaxies.

While on the Cape of South Africa, Herschel and his wife Margaret produced botanical illustrations of local flora that are still considered reference works today. He wrote numerous papers and articles, and along the way, translated Homer’s Iliad into English. Herschel investigated color blindness and correctly figured out that astigmatism was an irregularity of the cornea.

His buddy Charles Babbage invented the predecessor to the modern computer. Another friend, George Everest, was the Surveyor General of India, for whom the tallest mountain on Earth is named. Sir Herschel speculated on the transition of languages and animal species over long periods of time. He was visited in South Africa by the young naturalist Charles Darwin who would later credit Herschel as an influence on his theory of evolution. The two scientists are buried side-by-side in Westminster Abbey.

I suppose that Sir Herschel would approve of how the modern computer, the descendent of his friend Babbage’s invention, has been integrated with the inkjet flatbed printer, a distant descendent of his own flatbed blueprint process, and evolved into the core of the modern reprographic shop.

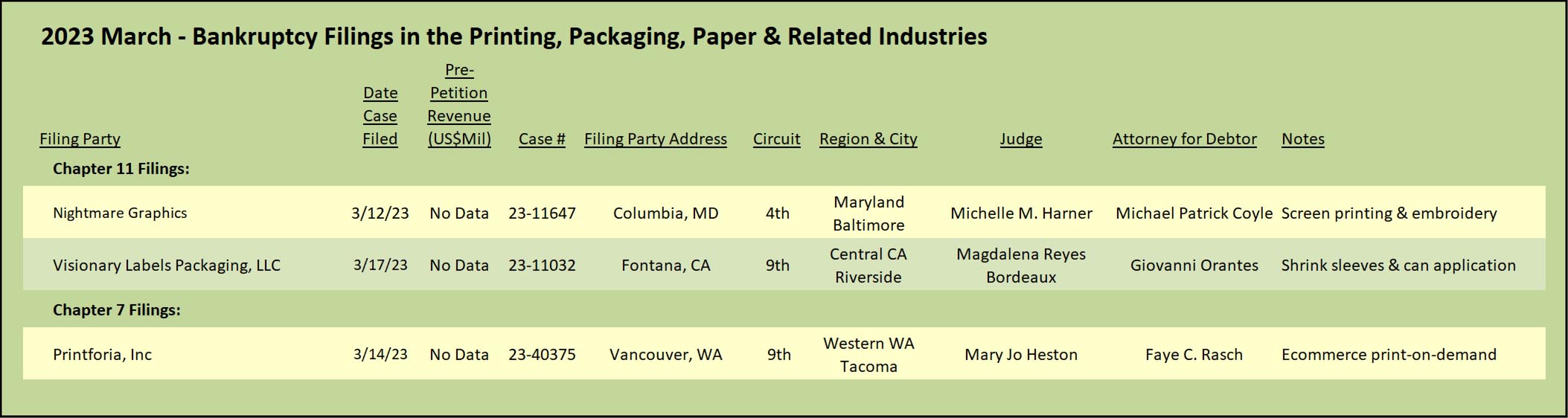

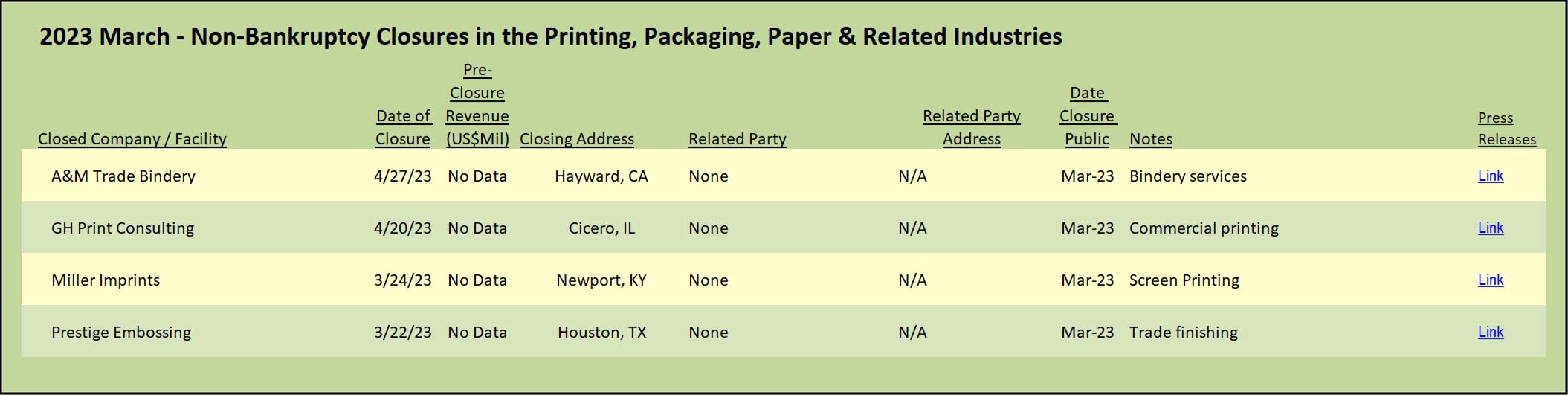

View The Target Report online, complete with deal logs and source links for March 2023

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free