In the label and packaging world, there are several ongoing trends that are triggering an increase in the number of short run jobs. As brands look to differentiate themselves along with the rise of specialty/craft brands, the number of products and SKUs in the world is growing.

For converters, it means more jobs in production, and, as a result, more spot colors (typically Pantone colors) to match. This has significant implications on production since, based on our data, color matching takes 15–30 minutes per job. For labels, consistent color takes on supreme importance since consumers equate quality of the package with the quality of the product itself.

There are three traditional ways in which converters are dealing with this issue today:

- Color Geeks [Full color management process]—Color experts typically print their own “spot color” book for a specific media and specific ink set. This can be a long and expensive process: deep press baseline, profile building for each ink set, refinement for all Pantone books, and the cost of time for expert who is in control of the process.

- On-Demand Refinement [Job level color management process]—Performing spot color refinements according to the job content. In this case, the converter performs an iterative process of printing the jobs’ spot colors with different ink set recipes, with each iteration attempting to get closer to the target spot. This process is time consuming and often quite difficult to replicate.

- LUT Lovers [No color management process]—Matching spots on the press according to what the press operator sees with his own eyes and based on LUTs (Look Up Tables) and ink level (channel) adjustments. This process is based on trial and error and is not a repeatable process; each change influences other channels and is quite labor intensive.

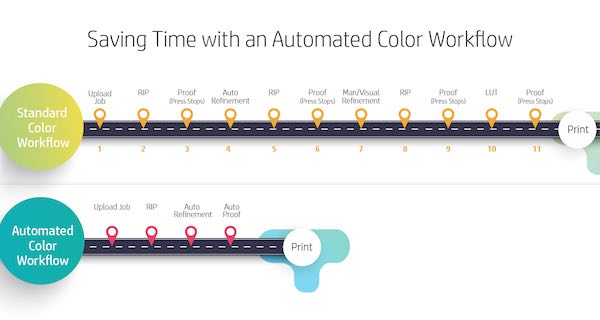

Standard vs Automated Color Workflow

Clearly, each method has its own pros and cons, but they all take a long time, require a highly-skilled operator, and are not scalable when the number of jobs increases—and consequently the number of spots-to-match, grows. So, what is the solution? Is there a spot color matching process which is easy to use, takes a short time, does not require high skills, and is repeatable?

Well, the answer is “it depends.” In analog printing, there is no real way to automate this cumbersome process. But, when using Indigo presses, the answer is a resounding “yes.” Using the internal spectrophotomenter, a color measurement device in the press, along with sophisticated software, the entire process can be fully automated.

Basically, this means a system that will:

- Automatically detect which spot colors are being used in the artwork and their target L*a*b values.

- Automatically print and measure the spot colors’ actual L*a*b values and compare with the target L*a*b values. Change the spot recipe as needed and repeat this step until the result is the closest possible to the target, i.e., the minimal measured delta-E which is the difference between the target color and actual color achieved.

- Automatically print the job using the correct recipe while continuously monitoring the spot colors and adjusting as needed.

- Save the parameters and ink set recipe for reprinting the job.

In fact, this is HP Indigo’s “Spot Master,” and it does all of the above. Spot Master (see demo) is the latest color matching technology that allows converters to reach brand colors in less than five minutes, and maintains color consistency across the entire frame all along the run, so that every package will always look the same. In my opinion, this is the fastest time to accurate spot colors in the industry.

So, what’s your approach? Do you have any tips or observations on color automation?

To view the entire Workflow Chef series and other relevant sponsored content from HP Indigo, visit https://whattheythink.com/topic/hp-workflow-chef/.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free