To produce accurate and consistent color, you need to repeatedly measure the printed colors and compare them with the target. The more you measure, the faster you identify and fix any color deviation.

However, two potential issues come to mind:

- The measurement process takes time and effort and reduces the availability of the press, thus reducing your OEE percentage

- Analyzing the results and concluding what corrective actions to take require a highly skilled color expert and can be expensive.

To measure colors, the press operator needs to print a sheet with color patches. Next, the patches are scanned using a spectrophotometer (either manually or automatically, by using a small robotic arm). This process typically takes up to 15 minutes—and this is time during which the press is idle and does not print.

Color correction is a repetitive, time-consuming, and complex process. To optimize it, we need to focus on two things: automation and simplification.

Automation

Some digital presses have an internal spectrophotometer that can move across the printing direction and automate the scanning. In the case of the HP Indigo 100K digital press, the moving spectrophotometer is placed at the exit of the proof tray, enabling the press to continue to print while the patches are being scanned. This means no downtime while scanning, but it also means the press can change the color settings automatically and it doesn’t have to be done manually—which can be a very time-consuming process.

Simplification

The scanning and the analysis process that follows it produce a lot of data. For example, the color values of each patch (typically in L*a*b* format) and the visual distance from the target colors (usually measured as delta-E or dE), the density of the solid colors, values of the colored grays, and more. Analyzing that data and concluding the actual color status, as well as concluding what steps should be taken for each type of issue, are complex tasks that require a color expert. And unfortunately, color experts are expensive and rare.

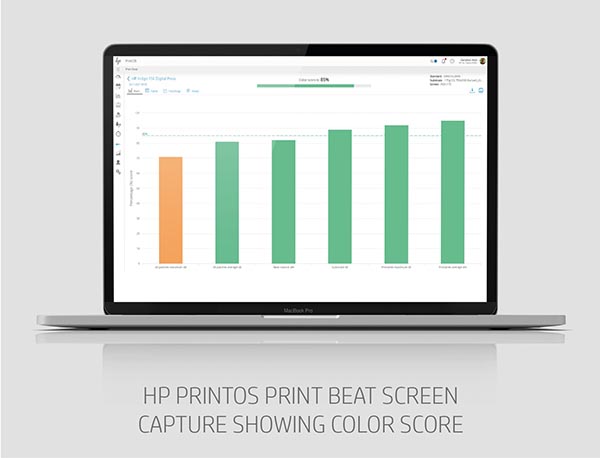

One good solution is to use sophisticated software that analyzes the data and produces scores for accuracy, uniformity, dot gain, and other parameters, as well as a single summary color score. Each score has a clear pass/fail status and adds recommendations for corrective actions. The scores can be accessed by all employees, or by another software solution through APIs, anywhere and anytime.

Using such an automated and intelligent color monitoring system brings both operational and business advantages. One of our customers, a large photobook printer, used to stop his presses every two hours for up to 10 minutes to measure color. Today, using the fully automated system, the presses print continuously, increasing their productivity. And more importantly, the satisfaction of his customers has reached new levels!

To view the entire Workflow Chef series and other relevant sponsored content from HP Indigo, visit https://whattheythink.com/topic/hp-workflow-chef/

Discussion

By Ben Sachs on May 12, 2021

I am an printing industry specialist with over 50 years experience. Currently my work involves delivering electoral processes for African Elections across the sub-continent.

My particular interest is in the production of ballot material for electoral voting processes having completed over 30 elections since 1999 in Africa and together with a number of other companies we have sustained, promoted, and delivered free and fair elections across the African continent.

The delivery and production of voting material across the African continent has hitherto been outsourced mainly to about 6 companies in SA, UK, France and Dubai.

The challenge is to encourage the insourcing of the the production of ballot forms for voting across the continent in order to reduce the costs of electoral processes and reduce the hundreds of airfreight flights that contribute to carbon emission as an objective, besides tackling the issue of continued colonial exploitation in the supply of materials.

The discussion on ink jet production seems to be very much the future direction and I am in search of technology to deliver these services.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free