- Diverse, creative options enable PSPs to stand out from their competitors and attract the attention of consumers.

- To tie finishing procedures to business results, finishing must be monitored closely and included as part of the billing process.

- Because offset and digital do not always make the best finishing partners, many PSPs struggle with whether to segregate or combine their offset and production digital print capabilities.

By Mark DiMattei

Introduction

Although finishing occurs at the tail end of a printing project, it is an important and value-added step that cannot be overlooked. Finishing capabilities can range from simple (e.g., trimming, folding, stapling) to complex (e.g., cutting, embossing, binding, or print enhancements). Thanks to ongoing technological advancements in digital printing, many finishing methods can now occur in-line with production digital printing devices. In 2020, Keypoint Intelligence conducted a survey of print service providers (PSPs) in North America to better understand their perceptions about the role of finishing. This article explores how PSPs can leverage today’s finishing capabilities to maximize the effectiveness and profitability of their printed offerings.

The Research Findings

In early 2020 (pre-COVID), Keypoint Intelligence surveyed 120 PSPs in North America about their finishing preferences. Survey participants worked for companies with a mix of offset lithographic and production digital printing equipment. Although 86% of respondents had sheet-fed production toner digital printing equipment, offset processes were also quite common. Well over half of respondents (58%) were operating sheet-fed offset presses.

Finishing Closes Deals and Provides Market Differentiation

According to Keypoint Intelligence’s Market Trends in Print Finishing study, many PSPs report that finishing has helped them to win deals. In fact, only 11% of respondents reported that they had never lost a deal due to finishing requirements. Among those respondents who had lost deals because of finishing requirements, the most common reasons included:

- Not having the required finishing capabilities (54%)

- Price (40%)

- Turnaround time (32%)

All three of these factors can feed upon one another—if you don’t have the right capabilities and therefore need to outsource that part of the job, price and turnaround time can be impacted.

In addition to closing deals, finishing can also serve as a differentiator. Diverse, creative options enable PSPs to stand out from their competitors and attract the attention of consumers.

Future Purchasing Intentions

When PSPs were asked about the frequency of their finishing equipment purchases (new or replacement devices) the average duration was 3.7 years. In addition, 65% of survey participants had not made any finishing purchases in the past three years. The relative infrequency of finishing equipment purchases poses challenges for PSPs and finishing system vendors alike, and these issues have likely only been exacerbated as the onset of COVID-19 caused many PSPs to re-evaluate their budgets. As a possible solution, finishing system vendors should consider working more closely with digital printing equipment vendors. PSPs may be more receptive to investing in finishing capabilities if this equipment is sold (and financed) along with digital printing devices. End users must also be better educated about the value that finishing can deliver.

Calculating Finishing Costs

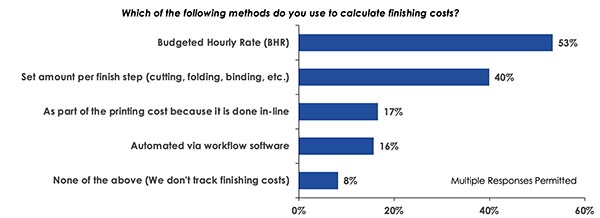

To tie finishing procedures to business results, finishing must be monitored closely and included as part of the billing process. Budgeted hourly rates (BHRs) were the most common method for tracking and charging for finishing among our survey respondents. Simply put, BHRs consider factors like general expenses (rent, utilities, insurance, etc.), employee wages, and equipment costs to determine an hourly amount that the operation must cover to reach break-even status. This sets a cost base for the determination of pricing levels that help the business achieve profitability.

Another popular method was to charge for finishing using a set amount per finishing step (e.g., adding charges for trimming, folding, or binding). When finishing was accomplished in-line with a digital print device, some respondents reported that they bundled the cost of finishing in with the cost of print, because the operations happened simultaneously. Other respondents automated their cost calculations using workflow software. This aligns well with the use of BHRs, since these types of calculations typically form the underpinning of automated cost calculations.

Figure 1. Methods for Calculating Finishing Costs

N = 120 Print Service Providers in North America

Source: Market Trends in Print Finishing, Keypoint Intelligence - InfoTrends 2020

Offset vs. Digital

Because offset and digital do not always make the best finishing partners, many PSPs struggle with whether to segregate or combine their offset and production digital print capabilities. Longer offset runs may be better suited to finishing via dedicated manufacturing tools where there is less focus on quick setup. Meanwhile, the shorter runs and quick turnaround requirements of production digital print do not lend themselves well to devices with long setup times. Additionally, with the current proliferation of high-speed inkjet digital printing systems, there comes a requirement for higher volume and productive finishing tools that bring new capabilities for finishing workflow and automation, whether offline or in-line.

According to Keypoint Intelligence’s research, respondents with both digital print and offset press technologies generally preferred to use the same finishing equipment for offset and digital. A smaller share preferred to keep offset and digital production separate. Others reported that that combining digital and offset was not feasible due to format and other requirements. In-line finishing is also quite prevalent with digital print, which can make it difficult to share resources across offset and digital.

Figure 2. Use of Offset and Digital Finishing Equipment

N = 70 Print Service Providers in North America who have digital and offset printing capabilities

Source: Market Trends in Print Finishing, Keypoint Intelligence - InfoTrends 2020

The Bottom Line

Finishing may be one of the final steps for many print applications, but it shouldn’t be ignored until the end of the process! Although there is still work to be done, most PSPs understand the value and benefits that finishing can deliver. Now is the time to think about how finishing can be applied to other business decisions—especially when making new equipment investments.

Mark DiMattei is the Manager of Keypoint Intelligence’s Publishing, Editing, and News department. In this capacity, he oversees the formatting, editing, and publication cycles for many different types of deliverables. He also assists in the production of blogs, analyses, research reports, and multi-client studies.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free