The Packaging Lab Launches Simplified Pouch Production with HP Indigo 20000 and PrintOS

Press release from the issuing company

The Packaging Lab, a new digitally printed packaging film and pouch company, is launching operations this month, offering easy online design and ordering with industry leading turnaround time using HP Indigo digital printing and automation solutions.

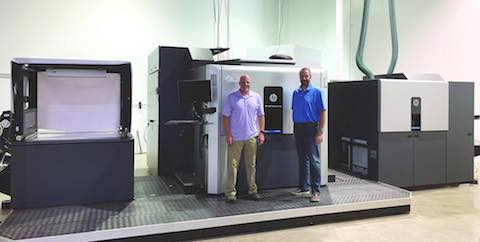

The greenfield company has installed an HP Indigo 20000 Digital Press at its 15,000 sq.ft facility in Minneapolis, Minnesota, creating a finishing line with Karlville Pack Ready lamination, slitting and pouching lines optimized for HP Indigo production.

The fully automated, online customer experience at thepkglab.com is powered by HP PrintOS Site Flow and Infigo web to print.

“The new concept will disrupt the industry by allowing customers to design and order custom packaging entirely through an ecommerce platform,” sayd Dan Niblo, CEO at The Packaging Lab.

According to Niblo, a 30-year packaging industry veteran, he Packaging Lab’s end-to-end automated concept is designed to fulfill the unmet needs of the changing packaging market. Consumers have come to expect almost immediate delivery of their orders via ecommerce. In today’s packaging industry, lead times – even using digital printing- can range from 6 weeks to 16 weeks.

The Packaging Lab vision is to provide as fast as 24-hour to 5-day maximum turnaround, offering a flat fee for design services, and no tooling costs or minimum orders. Easy online design and ordering will be powered on thepkglab.com by Infigo Catfish, walking the customer through everything including pricing without the need to “fill out a form and wait for a call.”

Next, Infigo Catfish submits orders to HP PrintOS Site Flow without human intervention via the PrintOS open API. Site Flow automatically batches like-jobs, applies step-and-repeat, adds finishing marks and submits the batched job to the HP Indigo 20000 digital press.

“Using PrintOS Site Flow, we can fulfill hundreds or thousands of online orders per day with minimal staff,” Niblo says.

The 30-inch HP Indigo 20000 Digital Press provides converters the freedom to produce nearly any flexible packaging application on film or paper with unlimited variation thanks to the new HP Production Pro for Labels and Packaging digital front end with multiple RIP instances for variable data and to support for growing SKUs.

An additional advantage of The Packaging Lab digital model is savings on waste due to flexo minimum order requirements. “I could tell you many stories of tens of thousands of dollars of waste due to product change or mistakes using Flexo. We won’t have that issue here,” says Niblo.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Only verified members can comment.