What if you could quickly, easily and accurately calculate the carbon emissions any printing job as part of the estimating process? And what if you could shift the burden of neutralizing those emissions to the client? With a couple of tweaks, a new online tool might be just what you are looking for.

Carbon offsets for printing jobs? Some people swear by them, some at them, but I think there is general agreement that calculating an accurate emissions profile of a printing job as a basis for offsetting carbon is a pain in the neck. And paying for those offsets is a pain in the printer’s wallet.

But what if you could quickly, easily and accurately calculate the carbon emissions any printing job as part of the estimating process? And what if you could shift the burden of neutralizing those emissions to the client, letting them take a more active role in managing the environmental implications of their printing purchase?

That’s the idea behind

ClimatePartner Footprint Manager, a web-based tool for calculating and neutralizing the carbon emissions associated with printing.

Developed by ClimatePartner, a Munich-based climate protection consultancy, Footprint Manager offers an alternative to cumbersome, one-off carbon-emissions calculations and associated carbon-offset purchasing procedures.

The idea behind ClimatePartner Footprint Manager is to streamline the process of calculating the carbon emissions associated with a given printing project – including emissions associated with operating the facility’s physical plant. The software also generates a report based on those calculations, and presents an appropriate carbon-offset solution – with costs – that the printer can deliver to the client, who then has the option of investing in the offset.

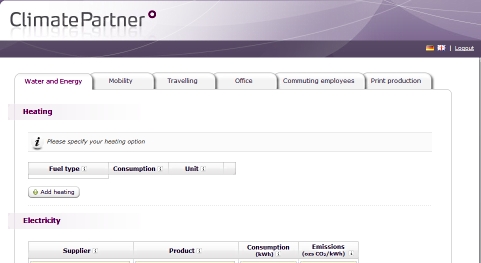

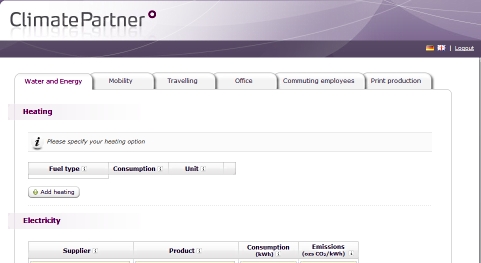

Here’s how it works. A printer registers for the online service, entering a plethora of data about the facility’s energy consumption and sources, presses and bindery equipment, vehicles, ink and paper usage, and even information about employee commuting. This data forms the foundation for calculating a facility’s carbon overhead – something that will be factored into the carbon calculations for individual print jobs. Footprint Manager calculates the facility’s carbon footprint, detailing the carbon emissions profile for the various categories of data. The core data must be updated annually, allowing the footprint report to be used as a benchmark to evaluate performance improvements over time.

When a request for estimate is received by the printer, the estimator enters the job parameters (paper type and volume, press utilization and time, bindery equipment and time, number of plates, etc.) into the web-based Footprint Manager tool. The estimator also selects an appropriate carbon-offset project from a draw-down list. (ClimatePartner has roughly a dozen carbon-offset projects in its portfolio at any one time. Most of the projects are in Asia, though the company now offers offsets from a methane-capture project in California.)

With everything entered, the software generates a report detailing carbon emissions associated with the job, and calculates the cost of offsetting that carbon through the selected project. A PDF of the report can be generated with the click of a mouse, and this report can be appended to the printing estimate for the client’s consideration. If the client agrees to purchase the offsets, the order for offsets is placed, and the software generates a unique certificate-ID logo that can be placed into the artwork for printing.

According to

Mario Schilling, ClimatePartner’s Manager of eBusiness, for most printers, registering for the program comes with a one-time cost of less than $1,000, there is a monthly fee of less than $300, and there is no contractual obligation. (Cost is based on the number of employees, rather than sales or throughput. Printers with 26 or more employees pay $1,500 to register and $375 per month) The cost of the offsets is additional and includes a small carrying charge for ClimatePartner, although the company doesn’t see this as a core revenue stream, says Schilling. Printers have the option of marking-up the cost of the offsets, but price transparency in the offset market will likely work against such an approach, says Schilling.

To be sure, the U.S. version of ClimatePartner’s Footprint Manager is an imprecise tool in its present state of development. There are a couple of notable gray areas in the input data that will need to be addressed – and quickly – if the tool is to accurately calculate the carbon emissions of an entire print job.

The first of these areas is “energy mix.” The mix of sources of electrical generation (coal, nuclear, hydro, wind, solar, geothermal, etc.) vary greatly from region to region across the United States. Some electric utilities are transparent about their mix of sources, and make the percentages of the blend readily available to customers. Others (and I daresay the majority of utilities) are far less forthcoming with this information. And without specific data on the types and percentages of electricity generating sources, no calculation can be any better than a best guess.

The second missing link relates to the paper (or other substrate) used for a given printing job. Many variables contribute to the carbon footprint of a given sheet. These include the type and volume of fuel used to run harvesters, processing equipment, pulp mill, and paper mill, the types of transport used to get the product from forest to market, and the distance the product must travel. Given the variables, two very similar sheets (for example, one domestic and one imported from Asia) can have very different carbon footprints. To my knowledge, there is no comprehensive database that contains this information for every type of paper used in the North America. Until such time as that database can be constructed, ClimatePartner will rely on “standard values” for various types of paper. While the calculations and offsets based on these standard values will likely overstate carbon emissions (which is better than understating them), they cannot be more than imprecise estimates.

Schilling is confident that ClimatePartner will be able to fill-in the gaps in the Footprint Manager tool in short order, and anticipates strong uptake of the tool by U.S. printers seeking to satisfy the needs of sustainability-minded corporate print buyers.

Additional information is available at

climateneutralprinting.com.

That’s the idea behind ClimatePartner Footprint Manager, a web-based tool for calculating and neutralizing the carbon emissions associated with printing.

Developed by ClimatePartner, a Munich-based climate protection consultancy, Footprint Manager offers an alternative to cumbersome, one-off carbon-emissions calculations and associated carbon-offset purchasing procedures.

The idea behind ClimatePartner Footprint Manager is to streamline the process of calculating the carbon emissions associated with a given printing project – including emissions associated with operating the facility’s physical plant. The software also generates a report based on those calculations, and presents an appropriate carbon-offset solution – with costs – that the printer can deliver to the client, who then has the option of investing in the offset.

Here’s how it works. A printer registers for the online service, entering a plethora of data about the facility’s energy consumption and sources, presses and bindery equipment, vehicles, ink and paper usage, and even information about employee commuting. This data forms the foundation for calculating a facility’s carbon overhead – something that will be factored into the carbon calculations for individual print jobs. Footprint Manager calculates the facility’s carbon footprint, detailing the carbon emissions profile for the various categories of data. The core data must be updated annually, allowing the footprint report to be used as a benchmark to evaluate performance improvements over time.

That’s the idea behind ClimatePartner Footprint Manager, a web-based tool for calculating and neutralizing the carbon emissions associated with printing.

Developed by ClimatePartner, a Munich-based climate protection consultancy, Footprint Manager offers an alternative to cumbersome, one-off carbon-emissions calculations and associated carbon-offset purchasing procedures.

The idea behind ClimatePartner Footprint Manager is to streamline the process of calculating the carbon emissions associated with a given printing project – including emissions associated with operating the facility’s physical plant. The software also generates a report based on those calculations, and presents an appropriate carbon-offset solution – with costs – that the printer can deliver to the client, who then has the option of investing in the offset.

Here’s how it works. A printer registers for the online service, entering a plethora of data about the facility’s energy consumption and sources, presses and bindery equipment, vehicles, ink and paper usage, and even information about employee commuting. This data forms the foundation for calculating a facility’s carbon overhead – something that will be factored into the carbon calculations for individual print jobs. Footprint Manager calculates the facility’s carbon footprint, detailing the carbon emissions profile for the various categories of data. The core data must be updated annually, allowing the footprint report to be used as a benchmark to evaluate performance improvements over time.