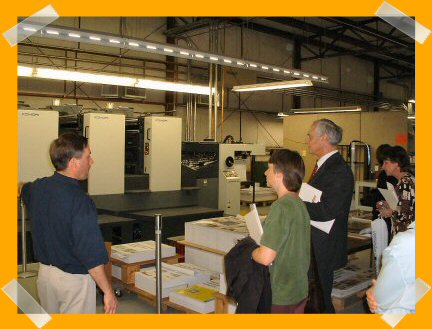

TigerPress Printing and Graphic Design of Northampton, MA recently hosted an open house to showcase their enlarged facilities. Live printing demonstrations, a facilities tour, and some very impressive take-away sample posters, marketing brochures, magazines, golf scorecards and other work samples, were on display for viewing and discussion.

|

|

Reza Shafii, President of TigerPress

|

Also on hand, were representatives from suppliers with whom customers could discuss specific applications for paper and finishing techniques. Kevin McCarthy, Branch Manager for The Pitman Company and Norm Fredriksen from Agfa were both on hand to answer questions concerning the Agfa Xcalibur 45 thermal platesetter- "A sweet little machine", in Agfa parlance.

|

|

Left: Kevin McCarthy; Branch Manager, Pitman |

In addition to the modern technology on display and volumes of high quality, four-color output to look at, Reza Shafii, TigerPress President, and his able staff had wonderful food and drink catered, and knowledgeable staff strategically stationed to ensure that every guest felt right at home. The open house gave all who attended a first hand opportunity to witness a very clean operation and talk with TigerPress staff about marketing and B2B communication solutions. It was easy to see why this company is enjoying remarkable growth in spite of these tough economic times.

Also on hand for this open house, was WhatTheyThink.com. We wanted to see for ourselves how this rapidly growing graphic arts service provider, with eight locations, was taking advantage of products from Agfa, Komori, Pitman and other companies to assist in their business growth. Following is an interview we conducted with Mr. Reza Shafii, President of TigerPress.

WTT: How long has Tiger Press been in business?

RS: We started as CopyCat in 1985. CopyCats now has seven stores, located in Brattleboro VT, Greenfield, MA, South Hadley, MA, Northampton, MA, Springfield and West Springfield, MA and Amherst, MA. In 1996, our original CopyCat shop's name was changed to TigerPress, and TigerPress became the print facility for all of the CopyCats.

WTT: In addition to general printing, what additional services does your company offer?

RS: We offer digital copying, color copying and Quick Print services at our print shops.

WTT: Can you give us an idea of your approximate annual sales volume?

RS: Around $5 Million a year.

|

| On floor proofing station matches digital ink jet proof with actual output from the Komori - adjustments are made on the spot! |

WTT: What kind of jobs do you primarily look for?

RS: We don't like to limit ourselves with any one type of job. We do a little bit of everything from brochures, newsletters, financial reports, catalogs and booklets. Once you limit yourself to certain types of printing, you lose the ability to change.

.

WTT: You are producing some very impressive Golf scorecards. Is this for local golf clubs, or is this a national business?

RS: Our TigerScorecard business produces scorecards for over 700 golf courses nationwide.

WTT: How do you think digital prints compare from a reproduction standpoint, look & feel to offset printing you are producing?

RS: Quality is very good on digital but on some digital machines that are toner based, you may see cracks on the fold that may take away from the overall quality. Also, the consistency of a long run is better achieved on an [offset] printing press. For short run jobs digital printing is the way to go.

WTT: Do you currently offer digital print capabilities in any of your stores?

RS: We offer digital printing at our CopyCat Print Shops. Not all of our stores feature the same digital printer lineup, but our selection includes the following machines: Doc 12, Doc 50, Ricoh 6513, Canon Image Runner105, Riso and Océ 3165.

WTT: How about direct imaging technology, do you see a place for the DI press in a traditional sheetfed or web shop?

RS: Yes, if there is a gap between the smallest press in the shop and the larger presses- for example, when the shop does not have a small 4 color press. A DI press can be an asset for short run jobs in a shop that has only larger presses. At TigerPress we are equipped with color copiers at our CopyCat locations, and have a 4-color half size and 6 color full size press in our TigerPress shop. So, there is very little room for the addition of a DI press in our operation

WTT: One could get the impression from your stable of Komori presses (2 color-28" perfecting, 4 color-28" and the newest 6 color-40") that you are really sold on them. Can you comment on why you chose Komori over the competition?

|

|

TigerPrint's Komori

|

RS: We compared features, reliability, quality and price. Komori represented the best value to us. Their presses are backed by Komori's exceptional service, and our sales representative is excellent.

WTT: How important is a coating station to you business?

RS: Very important. It allows us to bring in a broader range of jobs and to stay with the competition. Our customers are becoming more knowledgeable about final finishing, and they expect us to offer coating.

WTT: You are using Agfa's Xcalibur-45 Direct to Plate Platesetter. Can you comment on why you selected Agfa?

RS: We chose the Agfa brand based on its ability to run a wide variety of plate sizes along with the promise of no-process plates in the future.

WTT: What was the main influence for adding Xcalibur's thermal platesetter technology?

RS: When we added the Komori 40" press.

WTT: Do you view computer-to-plate as a temporary step until on-press imaging is more widely available?

RS: We feel computer-to-plate will be around for at least 15-20 years, until spray-on emulsions take over.

WTT: Have you kept an imagesetter in your workflow as backup or for some customers who do not want to use computer-to-plate?

RS: No, the expense of keeping two processors active is too high.

WTT: What benefits are you enjoying from the Direct-to-Plate workflow?

RS: Cost, job turn-around time, quality and consistency of work and make ready. Dot gain has also been reduced from 23 to 15% and highlights and shadows from 2-98%. So, all in all, we get less gain, sharper image and faster turn-around.

WTT: You are using a wide format digital proofer. Is this your only proofing method?

RS: Yes, we produce two-sided imposition proofs and contract proofs.

WTT: Has implementation of computer-to-plate changed your proofing process, or the type of proofs used?

RS: No, we switched to digital proofing prior to adding CtP capabilities, over one year ago.

WTT: How do you communicate with customers using proofs?

RS: We use a variety of methods that include a messenger, FedEx and visits with sales and production personnel. We also use e-mail on an occasional basis.

WTT: Your digital prepress manager (Wayne Gustafson) indicated that you are using Monaco Color as your color management system. What influenced your decision to choose Monaco?

RS: Through the recommendation of our dealer, Pitman.

WTT: Has Monaco reduced the number of proofs per job?

RS: Yes, by color managing our scanner, we rarely spend time adjusting scans.

WTT: What RIPping software are you using?

RS: We are using Rampage for RIPping and for our entire workflow.

WTT: How has telecommunication changed your workflow?

RS: We now use electronic file transmission rather than physical transport of films and files between our own shops and with our customers.

WTT: What publishing environment are you working in?

RS: All of our workstations are networked, and we use Quark, Freehand, Illustrator, PageMaker and Indesign.

Thank you Reza for spending time with us and sharing your thoughts with other members at WTT.

Visit the Tiger Press web site at www.tigerpress.com.