The Stationers across the country are up in arms! Shock waves hit this specialty corner of the printing industry on Valentine's Day, certainly ironic timing for printers and print distributors that specialize in messages beautifully printed on beautiful paper. Workers at the Crane Stationery division of Mohawk Fine Papers were notified the day before Valentine’s Day that they were laid off effective immediately. Social media buzzed among the stationery cognoscenti that the employees were locked out of the company and their email was turned off. Remote workers received the same message via a FedEx letter. The Crane website went offline, except for the cryptic message “We are Taking a Moment to Reflect” and a bizarre quote, given the circumstances, from Coco Chanel that “Fashion Changes, But Style Endures.” Orders in progress from designers and printers that rely on Crane came to a screeching halt. Customers searched, to no avail, for information about when, and if, the company might resume operations and deliver those orders. The event is a small echo of the waves of change roiling the paper industry.

The wave that was the impetus for the Crane shutdown came across the ocean from the Italian papermaker Fedrigoni, which acquired the assets of Mohawk Fine Papers. The Fedrigoni Group is a manufacturer of specialty papers, self-adhesive materials, and RFID solutions. Founded in 1888, the company was acquired by Bain Capital in 2018. Despite the holiday, there was no love in the air when Fedrigoni reached the cold-hearted decision that the Crane Stationery division was not of any interest to them going forward. No funeral notice, no proper burial, just shut it down.

However, there may be more to this than meets the eye at first glance from the perspective of the aggrieved stationers. Fedrigoni made it clear in their press release that Mohawk Fine Papers was facing financial challenges and that they, Fedrigoni, were effectively the white knight in this situation, not the bad guys. In the press release announcing the deal, Fedrigoni noted that the sale process was “initiated by a financial institution, following a period of significant financial distress that affected the U.S.-based company in the past months.” There is no ambiguity in that statement; Mohawk was forced to the marriage alter by its lender and/or equity investors. Further positioning itself as the savior of the Mohawk company, Fedrigoni added that the “transaction entirely cleared the new company from existing indebtedness, allowing to preserve the majority of existing jobs, industrial activities, and customer relationships.” As we know at GAA from our work with financially challenged companies in the printing industry, the sudden shutdown of the Crane Stationery subsidiary may have been an unfortunate, but necessary, sideshow to the main event, which was saving Mohawk Fine Papers as an ongoing enterprise.

Crane Stationery has its own storied past. Its founder, Stephen Crane, participated in the Boston Tea Party, and Paul Revere used Crane paper for his engraved banknotes which helped finance the American Revolution. Shortly thereafter, Crane was printing currency and many other types of official documents. After a long and winding history that eventually led to the formation of the Crane Currency company, the manufacturer of specialty papers used to print paper money for more than 50 countries around the globe, the company was acquired in December 2017 by Crane Co. a similarly named but unrelated global engineered technology and manufacturing company best known for its ubiquitous toilet fixtures found in millions of homes, offices and factories. However, separate from the manufacturing of the currency papers, the rights to manufacture the well-known Crane’s Bond, a wonderful 100% cotton writing paper, had been sold off to Neenah Paper back in 2009. (For more, see The Target Report: Will the Real Crane Please Stand Up? – December 2017.)

In one more twist of the Crane legacy, in April 2018, Mohawk Fine Papers purchased Crane Stationery, including the printing operation in North Adams, Massachusetts. When Covid hit the country in 2020, the social events that drove the invitational business of Crane Stationery were canceled. Mohawk management then got into a spat with the Governor of Massachusetts over the essential nature of its printing business and the decisions about operating the plant. The Covid shutdown came shortly after the bankruptcy of Crane’s largest single customer, Schurman Fine Papers, the parent company of Papyrus mall-based retail stationery stores. Mohawk decided to close the Massachusetts factory, laid off over 200 employees and moved the remainder of the business to its Cohoes, New York, operation.

There may yet be redemption for the Crane Stationery company and its customers. WPS Holdings, an upstate New York investment firm, has announced plans to acquire and restart the Crane Stationery company. As of this date, the deal is not definitive as WPS attempts to extricate and separate the Crane business from Fedrigoni’s Mohawk Fine Paper company.

Mills and Converting Plants Closed

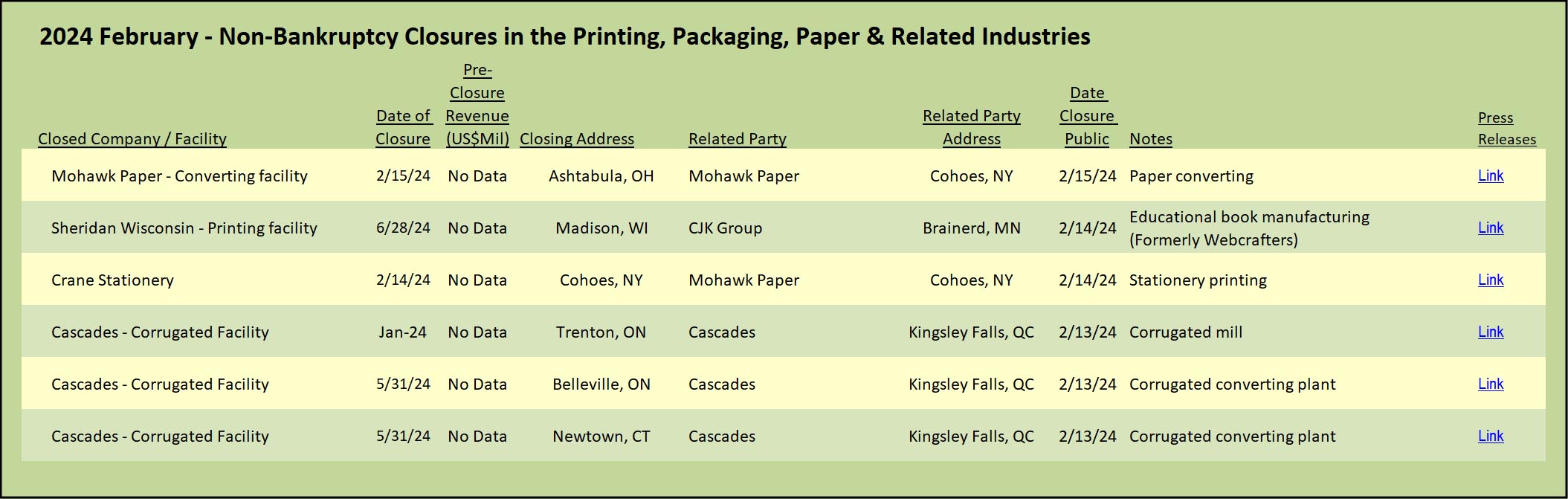

The papermaking industry continues to rationalize production capacity and capabilities. Announcements in February brought down the curtain on several other facilities. Mohawk’s converting plant in Ashtabula, Ohio, midway between Erie and Cleveland, was also hit in the Fedrigoni Valentine’s Day massacre. Employees there learned at the end of their workday that their jobs were eliminated, effective immediately and that the plant was shutting down permanently at the end of the week. In its letter to the dismissed employees, Mohawk indicated an exemption from the 60-day WARN Act advance notice requirement due to “very recent and unforeseen circumstances” which is often an indication that the company doing the layoffs is under significant financial stress, known as “faltering” in WARN-Act speak.

Canadian papermaking company Cascades announced that it was closing three facilities that it deems no longer competitive now that its facility in Bear Island, Virginia, is up and running. The recently idled corrugated plant in Trenton, Ontario, will be permanently closed. Two corrugated converting facilities, in Ontario and Connecticut, will be closed as well. The announcement was not one of doom and gloom, however, but rather a message of repositioning production into other facilities, including Bear Island, with available capacity and more modern equipment.

Paper Mill Changes Hands

In an expression of faith in the future prospects of fiber-based packaging, Clearwater Paper acquired the bleached paperboard facility in Augusta, Georgia, from Graphic Packaging. The transaction value was reported as approximately $700 million, based on adjusted EBITDA of $100 million. Clearwater justified the price paid with its projection that EBITDA would reach $140 to $150 million annually by the end of 2026.

Clearwater Paper was founded in 2008, as the papermaking spin-off from the Potlatch Corporation. Having jettisoned its papermaking operations, Potlatch fully transitioned itself into a timberland real estate investment trust with timber sawmill operations. The Clearwater name was not new to the industry – Potlatch traces its roots back to 1900 when Frederick Weyerhaeuser and a group of investors founded the Clearwater Timber Company to purchase prime white pine lands in North Central Idaho. The Clearwater name was retired in 1931 when the Great Depression forced the merger of several companies into the consolidated Potlatch Forests company.

Freed from the Potlatch forest operations, Clearwater Paper acquired tissue product companies and is now a leading provider of tissue products for many private label store brands, as well as paperboard products used in packaging. Gone from the company’s product roster are the fine printing paper grades of yore that Potlatch produced. Potlatch’s printing papers included my go-to coated sheets back in my printing operations days: the workhorse number one paper Vintage Velvet, and the wonderfully smooth and true-white premium paper, Quintessence Dull.

Paper Industry Transition

Papermaker Nekoosa, headquartered in Kimberly, Wisconsin, announced the launch of its new Dye Sublimation Transfer Paper. The specialty substrate is designed to take advantage of the growth in the dye sublimation printing process. The new paper works to transfer digitally printed images to hard surfaces including ceramics, metal, glass, wood, and fiberglass, as well as fabrics used in apparel, flags, banners, and signs. The new product is paper used for printing, yes, but it is not paper for printing brochures and the like. Instead, the new paper is used for the dye sublimation process of printing on everything else. (For more, see The Target Report: On-Product Printing Promotes & Protects – October 2023.)

It remains to be seen what additional changes will be made by Fedrigoni at Mohawk. Unlike the discontinued Potlatch coated sheets, my favorite uncoated paper, Mohawk Superfine, is still in production. However, we can say with confidence that the acquisitions, plant closures, repurposing of mills, and introduction of new paper products supporting new printing technologies will continue as the industry accommodates the changes in the printing and packaging industries. (For more, see The Target Report: Paper Industry in Transition – May 2022.)

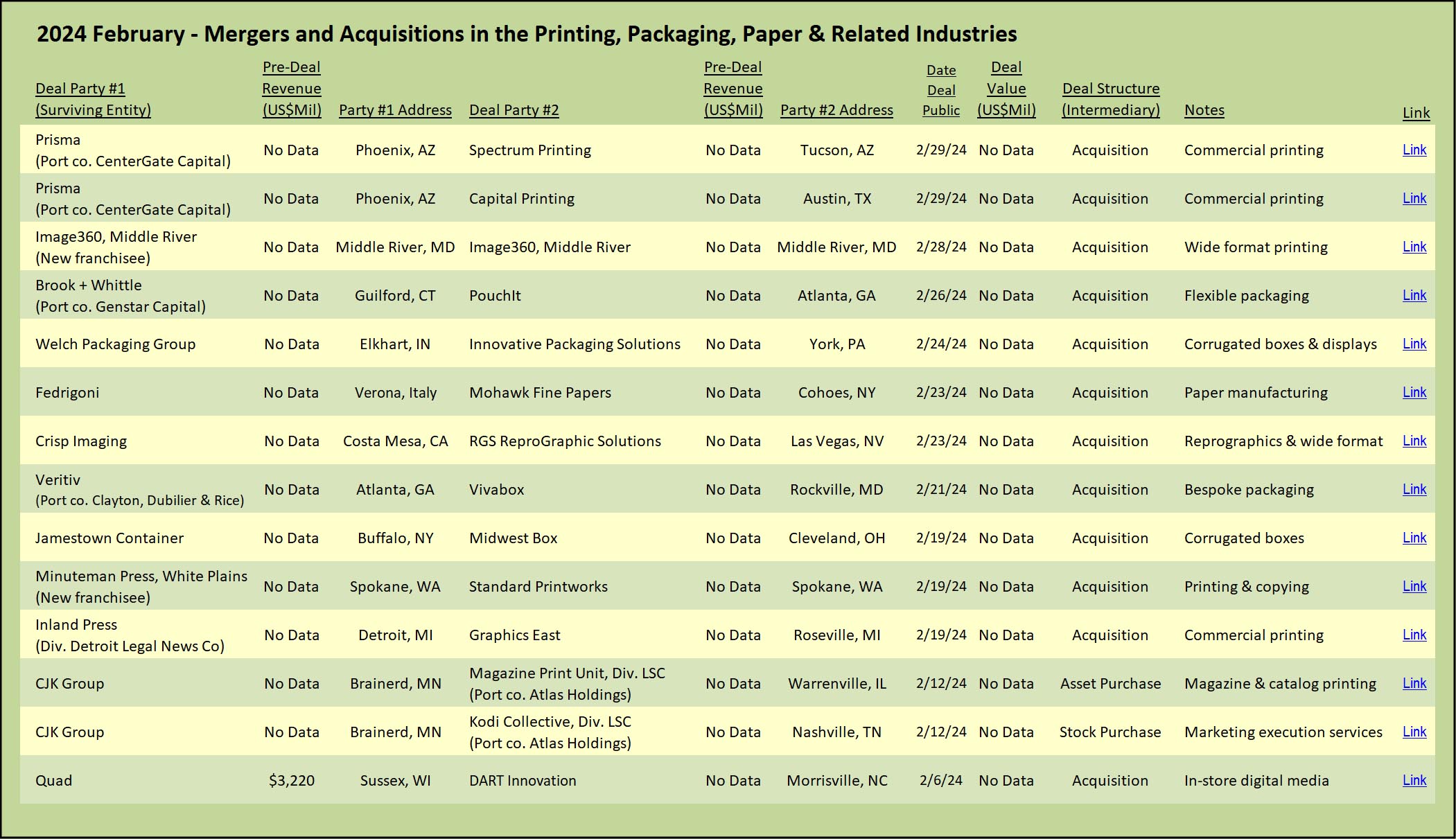

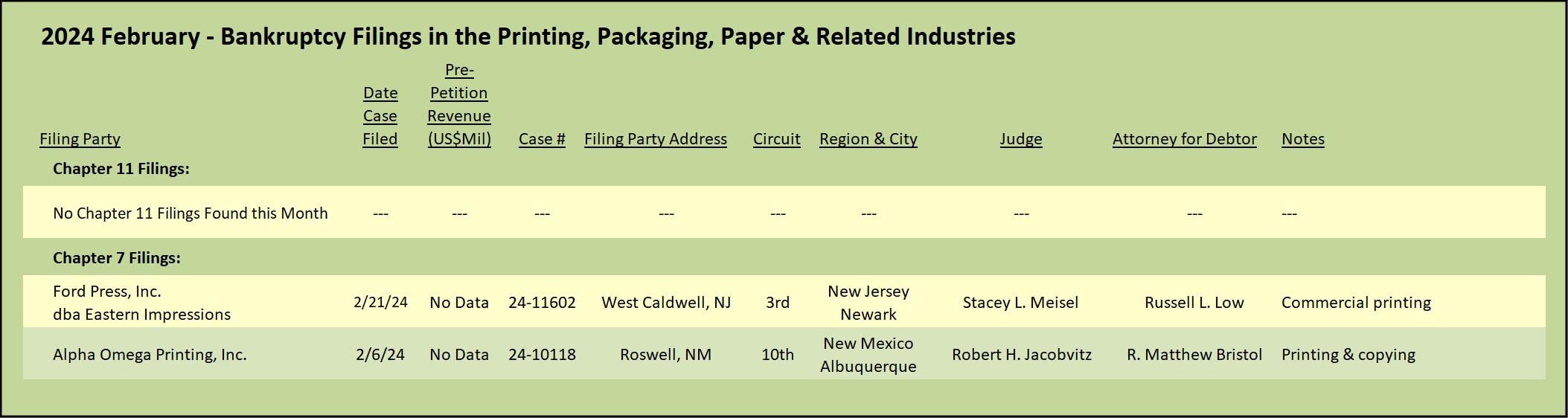

View The Target Report online, complete with deal logs and source links for February 2024