Originally published on Pixel To Parcel

Image Credit: Yanky & Nataf.

The Art of Fashion and Additive Apparel

Fashion by definition mirrors time. It captures and locks our vision of society and culture at a finite point. Each and every year, the fashion industry focuses the world’s attention using the global catwalk to make a statement. At each event the talents of the designer and their latest collections form a prism of creativity, capturing time and the latest advancements in technology.

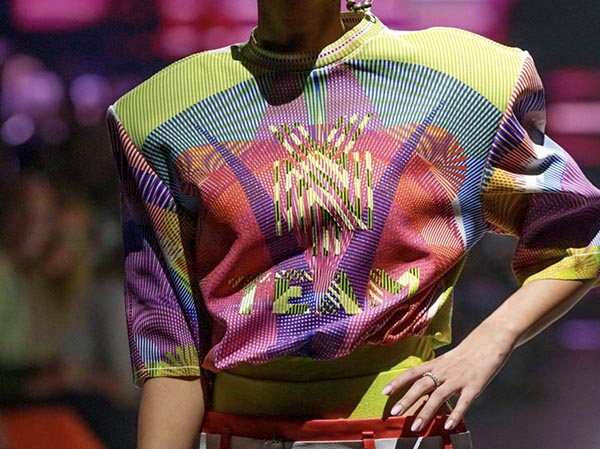

One such moment in Milan showcased the second collection by Yanky & Nataf, a dynamic duo setting the fashion scene on fire with their creativity. Yanky Golian and Nataf Hirshberg are the young creative minds behind the brand which was launched in 2018.

The creators graduated from Israel’s elite design institute Shenkar College and have since masterminded iconic apparel garments for a number of high-profile entertainers, musicians, films, and performances. Their work is vibrant, immersive, and playful, and harnesses the materials and technology of the moment to create stunning garments that emit energy and a powerful aesthetic.

Pushing the Boundaries of Design

Working with the design team at Kornit Digital in Tel Aviv, Yanky & Nataf have redefined the printed surface to create new age materials that enhance their own creativity. Their collection features fabrics with intricate printed surfaces that are more than technical, or tactile—they are adaptive.

Printing using neon inks brings the garments to life when exposed to UV light sources. Going further, they also created a 3D lenticular effect on the surface of the fabric, changing color and pattern as the surface is viewed from different angles, transforming the live view of the garment in real time.

Featuring a dress from their 2023 collection, “Vittoria” was printed using Kornit XDi technology to add a 3D printed design onto the surface of the fabric.

3D Digitally Printed lenticular fabric. Image Credit: Yanky & Nataf

White Inks Unlock New Creative Applications

Fashion designers can now add their own vision to their material of choice, enabling them to create customized fabrics and one-off, tactile surface effects. In a competitive fashion environment, this is a valuable asset, enabling them to create bespoke fabrics for their brands and luxury couture customers.

3D printing technologies are transforming the fashion supply chain. It is freeing the designer from traditional sourcing routes to offer on-demand fabric creation, luxurious surface effects and unlimited creativity.

Direct-to-textile 3D printing has been evolving for a number of years. First developed in the 1980s, the advanced technology we see today spawns a new chapter for personalized, customized printed surfaces.

White ink offers a new layer of creativity. Not only does it allow you to create surface pattern prints onto colored fabrics, it also allows you to add multiple layers of white ink to build highly imaginative 3D effects and new materials.

White ink printed on white mesh. Kobi Halperin collection for Kornit. Image by Harel Rintzler

Embellishments and Embroidery

Once the remit of only the most luxurious fashion houses, finely detailed embellishments can now be created on the fly and on-demand using 3D printing technology, liberating the luxury designer and their imagination. When printing using pigment inks, almost all fabrics can be printed and enhanced using 3D surface effects on cotton, wool, and synthetics.

Tatiana Pogrebnyak is a fashion designer based in Israel, creating unique, bespoke garments for an international VIP client base. Her collections now feature 3D surface effects created using Kornit Digital’s XDi technology. This represents a reinvention for luxury fashion and empowers the designer to enter new markets with exciting new products without the need for investment in highly skilled labor.

The Future of Creation and Technology Are Entwined

Technology continues to empower and ignite the creativity of a new generation that have sustainable manufacturing at their core.

As the fashion landscape evolves, the sector has and continues to be democratized by digital print and its ability to remove boundaries. In the field of fashion, competition is fierce. Reinvention is a basic discipline for the restless fashion designer.

As the fashion industry embraces the creativity of digital applications, it forges a new paradigm for the printed apparel industry for both roll-to-roll and DTG (direct-to-garment) applications. 3D technologies have been evolving for many years, but the technology we see today represents a new chapter and a new vision—made possible only by the advancement of ink-jet and science combined with creativity.

This is not functional apparel; it’s disruptive and offers the apparel industry and manufacturing community an exciting opportunity. Direct-to-textile 3D empowers the creator economy, and unleashes new commercial opportunities for customization and personalization. Image Credit: Yanky & Nataf.