I am still thinking about the Texprocess Conference in Atlanta last spring. At the show, I caught up with my friend Keith Hoover. I met Keith a few years ago when he was working at Under Armour and I was doing market research for Pantone. As an industry consultant, Keith has helped some leading brands digitize processes. He knows the savings brands gain when they move to a digital design and production process and eliminate 80% of physical processes.

When I spoke with Keith, we discussed digitization and digitalization. They sound similar, and it is common for people to confuse their meanings. Digitization focuses on the data required to objectively communicate product requirements, while digitalization is the process required to implement that workflow. In the past, Keith and I had passionate debates on this topic. Today, we agree that the apparel industry needs both to successfully lower costs, speed product launches, and deliver sustainability targets.

Why Digitization Is Important

Fifty-three million metric tons of discarded clothing are incinerated or go to landfills yearly. Another 14 million tons of waste comes from the textile manufacturers themselves for product waste and represents one-fifth of global water pollution. The apparel industry is essentially a spiderweb of brands and retailers working with manufacturers and suppliers around the globe. That spiderweb still communicates via phone calls, on-site visits, and physical swatches and samples posted around the globe. This hinders innovation and a brand’s launch timeline. A new product can take 18–24 months to get to market, and retailers are looking to drive innovation faster. To successfully do this, how brands communicate to suppliers must change; to go faster, digitalization and digitization are required.

Digitization (Aka Data)

The apparel and textile industry has been on a digitization path for years. But what does that mean? Digitization is taking a physical object and transforming it into a set of data that can be used internally with design and sales and externally with the supply chain and consumers.

Take color, for example. You need three basic things to see color: light, an object, and your eyes. The human eye perceives color differently based on factors like material, dyes or pigments, and the material. Viewing color with the human eye is subjective. In a subjective color evaluation process, physical swatches go back and forth between the suppliers and design team until the brand gets a “best can do” from the supplier. Many brands have color and material specialists who ensure that the color specified is accurately produced on the garments. Sadly, many apparel designers are not taught to use tools like a spectrophotometer, that can objectively measure and communicate color, and instead trust their eyes, which vary daily.

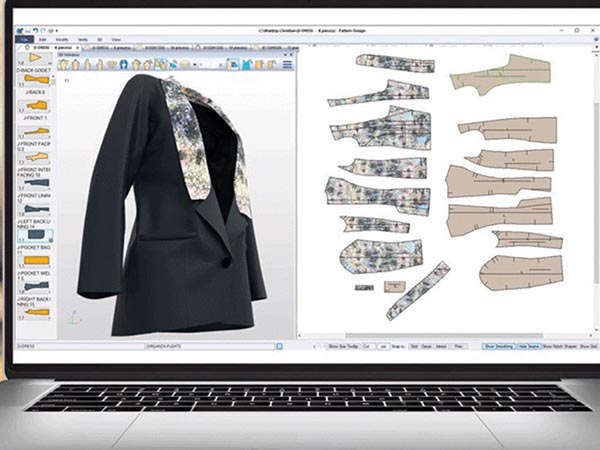

Digital patterns and fabrics in Gerber Technology Accumark.

To accurately digitize color and material requires objective data using a spectrophotometer.

When you leverage spectral color data, the color becomes objective, and the supplier can compare it to their dye sets and quickly responds yes or no. A good analogy is a paper roadmap vs. GPS. The roadmap gives you an idea of where you are, but GPS tells you exactly where you are and how far till the next turn. Using spectral data is the GPS, and a physical swatch is like the paper roadmap. A map is good, but GPS is precise.

Digitization also captures hidden issues in product development like metamerism. Metamerism is when two objects look the same under one lighting condition but different under another. If design approves a color on a material without measuring it and it goes to market, the person wearing the blue and white stripe shirt may look great inside, but if he went into a club, his shirt could look like it was designed by someone who was color blind.

Color is only one element of the digitization journey. Digitization is necessary for color, material, and patterns. Digitization is foundational but needs to be done correctly with data. More importantly, a lot of technology already exists. Companies like X-Rite and Vizoo scan in color and material, and Swatchbook has a library of digital materials that allow designers to interact with. The digital files contain spectral and appearance data. These swatches are connected to CAD fashion software like Lectra Accumark 3D or Browzwear. Whether it is getting buy-in from the design team to supporting an e-commerce site, using an accurate representation of color and material reduces design rounds and even customer returns.

Digitized textiles within Swatchbooks digital textile library.

Digitalization (Aka Process)

Once you have a color, material, constructions, and patterns digitized, then you need the processes to communicate it digitally. Today, design teams still go back and forth with samples and swatches. Prior to COVID, this took days and weeks. With current supply chain challenges, this can take months and companies can incur expensive shipping costs and even priority surcharges.

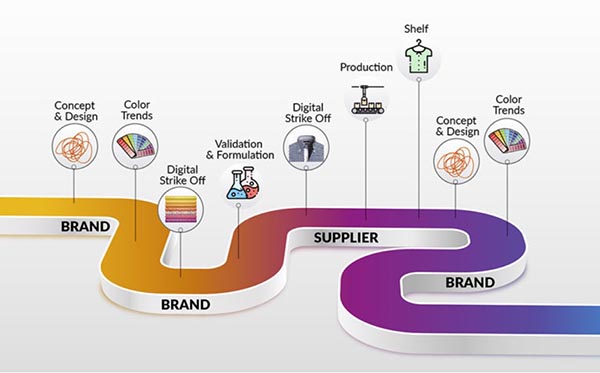

While digitization is about information and data, digitalization involves the strategy to adopt these digital assets into product workflows and monetize them. By adopting a digital process that leverage digitized assets, design teams have a set of guardrails to protect them and the brand. No one should spin their wheels back and forth trying to get something that simply can’t occur or can’t be produced. The guardrails allow design and product teams to work within the scope of what can physically be produced.

A digitalized workflow allows retailers to communicate inside a PLM with achievable color and material libraries. Email is replaced with a bill of materials (BOM) that has a pass or fail in reproduction. Everyone in the process can get a status on product development. A supplier 10 hours away knows precisely what they must produce, how to produce it, and is confident they can produce it. The endless rounds of swatches and “best can do’s” go away and become a “go do.” Digitalization works because it is built on a set of achievable, digitized data.

A digitized and digitalized workflow streamlines communication and can empower brands to launch in under three months.

Chicken Or Egg

Brands need to execute both digitalization and digitization to be successful. For example, a brand that invests in a product lifecycle management (PLM) system without digitized assets has simply generated a replacement for email. Having digitized assets without a process or digital workflows creates data with no means to quickly communicate and measure success. Instead, a streamlined and sustainable process demands digitalized assets and digital workflow.

Follow the Road to the Meta

Designers today are using a whole new set of tools beyond just pen and paper. Retailers can set their teams up for success by focusing first on the digitization of the brand’s assets and then creating the processes on how to leverage and communicate those assets. Meta is meant for “the beyond,” and a lot of brands are talking about the metaverse. Without digitized assets that accurately represent the product, the metaverse is no more than a fancy animation. To get on the road to meta, one first needs to take the physical and move it into the digital.

This article was provided by ColorKarma. ColorKarma focuses on design for execution by bringing together unique perspectives on design and manufacturing to ensure a smooth execution on your creative vision the first time. Our mission is to be the leading resource for the creative community providing educational content, industry news, design tips, and best practice advice from industry leaders.