This article is sponsored by EFI, makers of Fiery Preflight Pro, as part of WhatTheyThink’s Print Software Product Spotlight series. In preparing this article, the WhatTheyThink Print Software Section editors conducted original, in-depth research on the company and product. This Product Spotlight describes what the editors feel are the company and product’s strengths in the marketplace. EFI reviewed the final article for accuracy but had no editorial control over the content.

Background

EFI™ has been providing Fiery® DFE (Digital Front End) and workflow solutions for digital printers for more than 30 years. In fact, Fiery is the leading DFE platform for digital print, and can be found driving cutsheet or high-speed inkjet production printers from Canon, Xerox, Konica Minolta, Ricoh and Landa, just to mention a few. However, Fiery is also found driving many enterprise printers in offices as well. Over 30 years, more than 2 million Fiery servers have been installed worldwide.

As long as there have been digital printers there has always been a need to identify problems found in incoming digital files. Preflight applications have been around as long as digital print, usually as prepress applications that were developed to address those issues prior to printing. Standalone prepress preflight applications are usually fully featured, but require installation. They can be too complex for some less skilled users or even insufficient for unique applications, like those printing to a device from a variable data stream like VIPP or an application print driver.

Fiery Preflight and Preflight Pro

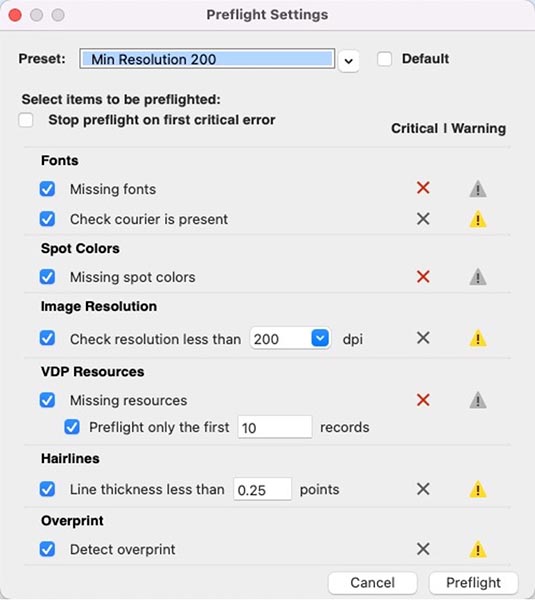

To address these issues, EFI internally developed and introduced Fiery Preflight as a part of the optional Fiery Graphic Arts Package in 2004. It was designed to offer basic preflight functionality for incoming PostScript and PDF files. This functionality includes checking for image resolution, available fonts, spot colors, hairlines, missing variable data resources, etc. Fiery Preflight also checked for job resources directly on the Fiery server (like missing spot colors), which was a unique capability. For example, other preflight software could call out spot colors but would not know if they were correctly configured on the Fiery server.

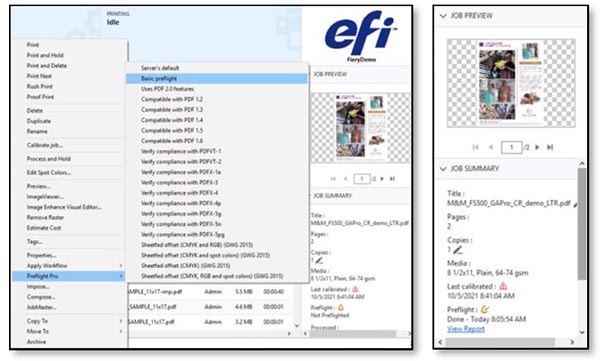

As designed, you can launch Fiery Preflight from Fiery Command WorkStation or you can assign preflight settings to Hot Folders to preflight incoming files.

Interestingly, while PDF is the preferred format for professional print reproduction, even today, between 60 and 70% of all jobs submitted to Fiery DFEs are PostScript-based, usually sent directly from the print driver. In fact, Fiery Preflight was originally developed to address one of the biggest issues users have with PostScript: the erroneous use of the setpagedevice operator. The PostScript setpagedevice operator is used to send instructions to the printer relating to paper attributes, finishing attributes, etc. Printing devices, if directly connected directly to an applications computer, can be polled for available options using the correct PPD (PostScript Printer Description) and print driver, so it is a very powerful feature. However, print devices that are not directly connected to the print driver can send instructions that are not available in the printer and can cause an error or produce unexpected results, like the wrong orientation of a page on the media. So EFI created specific setpagedevice fixes, so that you can set and override properties that you need from your incoming postscript file.

Fiery Preflight Pro

Today, some of the Fiery DFE servers increasingly support more powerful professional digital production print devices like the Nozomi, Landa, etc., and the recently introduced Fiery ImpressTM, a turnkey DFE for digital print and industrial applications. As a result, the DFE and preflight requirements have expanded beyond those of the legacy Fiery Preflight. EFI offers the optional Fiery JobFlow, which includes Enfocus PitStop, to address many of the prepress needs associated with the workflow and printing of PDF files to these new more powerful devices, but they determined that a powerful and inclusive Preflight solution for professional print applications was warranted.

Fiery Preflight Pro was recently introduced for Fiery FS500 Pro external servers as part of the Fiery Graphic Arts Pro Package, a set of tools that help customers identify and correct potential print problems before they result in wasted jobs, eliminating the need to go back to prepress or the designer. The intent, according to the company, was to provide a more powerful PDF preflight tool.

With Fiery Preflight Pro, EFI mainly focused on giving customers the ability to check incoming files against industry standards, like PDF/X, PDF/VT, and PDF 2.0, as well as those from the GWG (Ghent PDF Workgroup). The GWG has been developing and disseminating preflight profiles and test suites for 20 years in an effort to standardize process requirements and ensure files are processed correctly regardless of application, equipment or region.

Fiery Preflight Pro can be used with both cut-sheet digital commercial print devices and high-speed inkjet printers. It includes many of the capabilities of the legacy Fiery Preflight, except for PostScript support, in Fiery Preflight Pro. The company customizes how they deliver these standard industry common profiles based on the application of the DFE. For example, Fiery DFEs sold for commercial print will include different preflight profiles than a Fiery DFE sold for packaging or folding cartons.

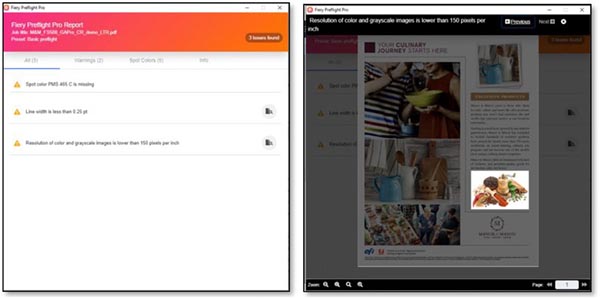

The preflight is done relatively fast and you can then see the file status. Any errors or warnings can be viewed in the interactive Fiery Preflight Pro report, which provides a visual overview of where specific errors in a file appear.

The variable data preflight has been significantly upgraded to support a more in depth look at the incoming PDF/VT files. The use of variable data has been increasing, however many of the variable data PDF files are nothing more than single documents with thousands of pages instead of embedded groups of variable objects since they were not created properly. The difference in processing time can vary greatly if the PDF/VT file was created properly, and Fiery Preflight Pro can not only identify whether the file is a PDF/VT-1 or a PDF/VT-2, it can also identify the file’s creation state and help predict processing performance.

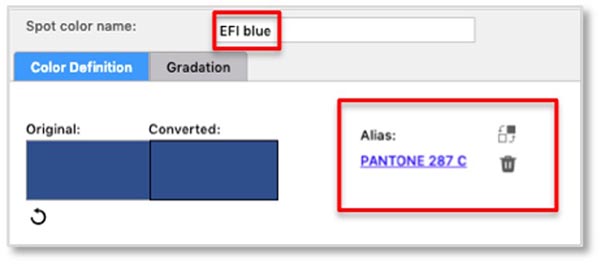

Another area that has been changed is data reporting on spot color information. The Fiery DFE includes color libraries that ensure the proper representation of a spot color on the connected printer. When a PDF file has completed the preflight, any spot colors identified in the file are checked against the embedded Fiery DFE colors database, and if they are missing, the user is alerted. Fiery Graphic Arts Pro Package offers additional tools to resolve missing spot colors. Using Fiery Spot Pro, the values can be added manually or through the use of a spectrophotometer, or you can adjust the color to match the alternate color values in the PDF. You can also use Fiery Spot Pro to manage existing spot colors and calibrate them against output to ensure the most accurate reproduction.

With Fiery Spot Pro you can also create spot color aliases. For example, if the original color in the database is PMS 287 C and you want it to also be represented as PANTONE 287 or EFI blue, you can just highlight it, type in the new name and create the alias. That way when the file comes in, the Fiery DFE will be able to identify the correct color in the database. You can also print a custom spot color swatch book to send to your clients to help set expectations.

Fiery FS500 Pro software

Fiery Preflight Pro is just one of the many new capabilities in Fiery FS500 Pro, the latest Fiery software platform, now available from Fiery OEM partners. Another advancement in Fiery FS500 Pro is Adobe Print Engine (APPE) 5.5, which includes support for PDF 2.0, including page-based output intents, black point compensation and much more.

More to Come…

I would like to address your interests and concerns in future articles as it relates to the manufacturing of Print, Packaging, and Labels, and how, if at all, it drives future workflows including “Industry 4.0.” If you have any interesting examples of hybrid and bespoke manufacturing, I am very anxious to hear about them as well. Please feel free to contact me at [email protected] with any questions, suggestions or examples of interesting applications.