MG America Introduces Patented Powder Dosing Unit for Simplified Manufacturing

Press release from the issuing company

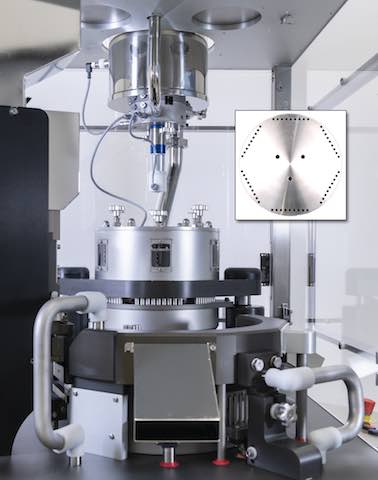

Developed for company’s AlternA70N Intermittent Motion Capsule Filler, EXTRUDOR™ system requires just one dosing disk for all dosages – resulting in easier, more consistent production and reduced product waste.

Fairfield, N.J. – MG America, the U.S. subsidiary of MG2 of Bologna, Italy and a leading supplier of processing and packaging equipment, debuted a newly patented powder dosing unit at Healthcare Packaging Expo 2019, September 23-25 in Las Vegas. The company’s EXTRUDOR™ is an innovative design requiring only one dosing disk per capsule size, regardless the dosage. The new system promises increased flexibility and reduced size parts.

Traditionally, capsule filling has necessitated different dosing disks depending on specific fill weights. By doing away with this mix-and-match approach, EXTRUDOR™ not only simplifies the capsule filling process, but also improves dosing accuracy and fill weight consistency by using a redesigned dosing container and dosing disk for excellent product layer uniformity.

The EXTRUDOR™ technology was developed for MG2's AlternA70N Intermittent Motion Capsule Filler, which is suitable for dosing and filling powders and pellets into hard-shell gelatin capsules. Capable of producing up to 70,000 capsules per hour, the machine features a tamping pin and can handle capsules ranging in size from 00 to 5, DB, elongated. The AlternA70N is equipped with a touchscreen operator-machine interface for easy control of all machine functions.

Another advantage of the new EXTRUDOR™ system is reduced product wastage, a result of a “capping” concept that maintains the powder inside the dosing disk and dosing container. This greatly diminishes powder loss, improves yields and reduces cleanup time and preventative maintenance costs.

For more information, call (973) 808-8185 or (toll-free) 866-962-3090, or visit www.mgamerica.com.

© 2025 WhatTheyThink. All Rights Reserved.