TPC Printing & Packaging Expands Range of Unique Special Effects For Its Elite Customers With New Koenig & Bauer Rapida 105 PRO 41-Inch Press

Press release from the issuing company

Leading luxury folding carton printer eyes new innovation, embellishments, and single pass productivity

- New Rapida 105 PRO 41-inch 10-color straight or eight-over-two perfector press is equipped with popular color control system, UV and LED curing, and cold foil system

- Sixth consecutive record-setting sales year for Chattanooga, TN printer that serves leading brands in the spirits, cosmetic and fragrance, over-the-counter pharmaceutical, and health and beauty segments

- Increasing trend in value-added specialty substrates, effects, and embellishments for high-end brand packaging

When the winners are chosen for outstanding design and production at an elite nationwide paperboard packaging competition, it is not unusual for TPC Printing & Packaging to be recognized by the judges and garner a number of top awards. This highly-decorated Chattanooga, TN-based boutique printer with an outstanding reputation produces a wide range of high-end custom folding cartons and promotional packaging for distinguished customers primarily in the cosmetics, fragrance, spirits, OTC pharma and health and beauty markets.

“We pride ourselves on delivering unique and innovative results for our discerning customers,” says Joseph A. Schmissrauter III, president of TPC Packaging. “We’re recognized in the Paperboard Packaging Council for producing extremely complicated packaging projects, which include the concept, design, print, performance, and shelf appeal of each of our award winning entries. With this national industry awareness, it’s easy to tout that we are the most prominent and innovative packaging printer in the country.”

That mandate has been woven into the daily production at TPC Packaging since its inception 95 years ago. Ever since J. A. Schmissrauter Sr. established the business in 1924, the third generation of the Schmissrauter family has followed this blueprint for success. In April 2019, the family celebrated this milestone event. Today, Joseph Schmissrauter III is joined in the business with his sister, Hilda Murray, and two brothers, Mark and Kurt Schmissrauter, who each have a dedicated market segment that they oversee. Now the fourth-generation of the family has become involved in the business.

Emphasis has always been placed on reinvesting in new technology to maintain the diversity and innovation required by its nationwide brand customers. In early 2020, TPC will address that need with the arrival of a new Koenig & Bauer Rapida 105 PRO 10-color 41-inch press, which will join an existing 2015 Koenig & Bauer Rapida 105 eight-color press. Schmissrauter and his team worked directly with his Koenig & Bauer sales manager, Sam Creel, to create a specialized versatile press that offers either 10 straight or eight-over-two perfecting, multiple inline curing units, combination LED-UV processes, full automation and color control, and the ability to handle multiple specialty substrates.

“The driving force behind adding a second Koenig & Bauer press is that TPC Packaging wants to continue to be recognized as the leader in innovative packaging in North America and give us that extra capacity to grow and continue to respond to the delivery demands of our customers,” said Schmissrauter. “Our goal is to consistently serve our world-class consumer retailers and well-known brand names better, and we are confident that our latest Rapida 105 PRO will help us do just that.”

Since its customers tend to test and try new techniques for their eye-catching packaging, TPC needs to quickly transfer important press presetting data directly to the console; the new Rapida 105 PRO 10-color press will be able to provide this quick data stream via the Koenig & Bauer LogoTronic CIPLinkX.

TPC places a high premium on delivering color consistency throughout the press run to ensure brand identity. An important consideration on the new Rapida 105 PRO is its ErgoTronic ColorControl color measuring inspection system, which will provide the ability to control and monitor color on every single sheet the press produces while improving efficiency and reducing makeready.

Once the new Rapida 105 PRO is installed in the first quarter of 2020, it will also offer another “first” that TPC will proudly be promoting. The firm will be the only supplier in the world with an inline Eagle cold foil system, an offline hot foil system, and a variable digital foil/polymer solution. The Eagle system will help TPC provide better in-line cold-foil options for its customers, accentuate brand packaging, and provide faster and more efficient cold foil-enhanced jobs.

When TPC decided to invest in a new press, there never was a discussion as to what press manufacturer they would choose, says Schmissrauter. Purchasing a new Rapida from Koenig & Bauer was a natural fit, he admits. The Koenig & Bauer team, including Sam Creel, sales manager, and Chris Travis, director of technology, provided the insight and direction to identify the key features for the new press order.

“Our current Koenig & Bauer Rapida 105 eight-color press continues to exceed our expectations,” says Schmissrauter. “Most of our jobs call for multi-passes through various packaging process presses. On average these complicated jobs can require nine machine passes. It’s even not uncommon for us to have a project that calls for 14 machine passes. Now instead of those two to three passes through the printing press per job, we will now only need to do one pass with our new Rapida 105. We will save millions of print impressions by running more jobs through in a single pass. And because our clients utilize high-end unique substrates, such as vat-dyed paper, foil laminated papers and holographic materials that can cost up to $2 or $3 per sheet, we’ll gain material savings as well. Plus, our customers are delighted with the press and its fully automated production, fast run speeds, efficiency, and short make-ready.”

Not long ago, TPC completed the rigorous yet satisfying certification process involved in becoming a G7 Master Printer. This qualification program identifies printing companies that have been trained to proof or print to G7 Neutral Print Density Curves and can meet print buyer requirements to produce proofs or printed output conforming to the metrics that reliably render brand images across print locations and different printing types. The qualification mark means that the printer uses the modern technology based on colorimetry, and employs G7 process controls. TPC proudly publicizes its important certification since many of its customers require G7 Master Printer certification.

Chattanooga, TN-based TPC Printing & Packaging is a highly-experienced, independent producer of high quality custom folding cartons and promotional packaging for a number of markets, including the pharmaceutical, food, spirits, and cosmetics industries. Founded by the late J. A. Schmissrauter, Sr. in 1924 as Textile Printing Company, TPC is wholly owned and operated by the third generation of the Schmissrauter family. It is considered one of the top-10 suppliers of fragrance and cosmetic packaging in the U.S. and one of the top-five packagers for the spirits industry. The company has won the prestigious Paperboard Packaging Council Innovation Award numerous times.

www.koenig-bauer.com

www.tpcpackaging.com

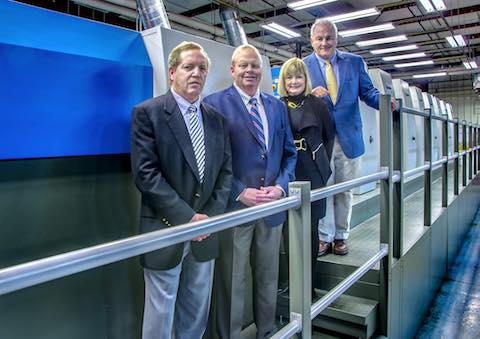

Left to right: Joseph A. Schmissrauter III, president of TPC Printing & Packaging; and his siblings, Kurt Schmissrauter, Hilda Murray, and Mark Schmissrauter, anticipate the arrival of a second Koenig & Bauer Rapida press at their Chattanooga facility.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.