Labelexpo 2019: Automated Label Production with Screen GP Europe and OneVision Software

Press release from the issuing company

Label converters benefit from shorter preparation times, higher throughput and increased profitability with the seamless integration of OneVision's automated label software Label Automation Suite with Screen's Equios workflow. At booth 9B30, printing press manufacturer Screen and workflow partner OneVision Software are demonstrating an end-to-end workflow for label printers.

Regensburg / Amstelveen – "Less waste, less material consumption and more economical working." This is the conclusion drawn by Dr. Benjamin Rüdt von Collenberg, COO of the German label printer “InForm Etiketten”, after having switched to an automated label production process by utilizing the Label Automation Suite.

At the industry event Labelexpo from 24 to 27 September in Brussels, high-speed printing machine manufacturer Screen and automation software expert OneVision are presenting a holistic production process from incoming orders over automated print file preparation in prepress and production planning to finishing preparation and machine actuation.

Seamless system integration for an end-to-end workflow

By directly integrating OneVision's Label Automation Suite into the Equios workflow, the software can actuate SCREEN's Truepress Jet L350UV+, that delivers industry-leading speeds for a digital label system of up to 60 meters per minute and ensures both, outstanding quality and throughput with its prominent inkjet-head technology.

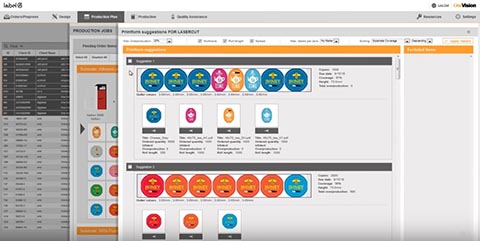

While the Label Automation Suite acts as middleware between the MIS and the RIP/DFE, covering the automated preparation of print files and the finishing process (e.g. automatic creation of varnish masks, cut line management, barcode generation) and production planning (collective printing of different jobs), Equios focuses on the ripping of PDF files, queue management, high-end screening and the adjustment of colors and spot colors. In day-to-day production, the Label Automation Suite automatically supplies Equios with optimized and nested PDF files including all required register marks, correct bleed, and white and varnish masks.

The Label Automation Suite's user-friendly user interface allows print data to be checked, corrected and prepared for printing quickly and uncomplicatedly.

Label printers benefit from shorter production times and higher job throughput

As a result, label printers achieve faster production times, higher job throughput and maximum utilization of the Truepress Jet L350UV+ by automatically providing properly set-up print data.

Label printers benefit from a full end-to-end workflow with the direct interface from the Label Automation Suite to Cerm's MIS (Management Information System). The MIS structures the administrative workflows of label and commercial printers. The direct integration with the Label Automation Suite allows job data to be transferred directly from the MIS and job tickets to be created automatically that initiate and control automated further processing of the files.

Explore the latest version of the Label Automation Suite and Equios Workflow at the Screen GP Europe 9B30 booth.

Get a first insight of how an automated label printing process can look like: Data preparation reduced from 120 to 15 minutes

Further links:

- https://www.onevision.com/solutions/label-printing/

- https://www.screeneurope.com/live/labelexpo2019/index-en.php

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.