Cerm & OneVision Software AG Announce Technical Cooperation

Press release from the issuing company

German workflow software expert OneVision Software enters into technical based collaboration with Cerm, one of the leading solution providers of business management software for narrow web label printers. The primary focus of the two companies is to integrate their software and to enable an automated end-to-end workflow for a smooth, highly efficient label production.

Regensburg / Oostkamp – The technical partnership between the two software manufacturers OneVision Software and Cerm provides traditional and digital narrow web label printers with a consistent automation of their label production. Due to the full compatibility and the direct connectivity of the two systems, order management and print data processing operate flawlessly.

Seamless integration between MIS and PDF workflow software make label converters benefit

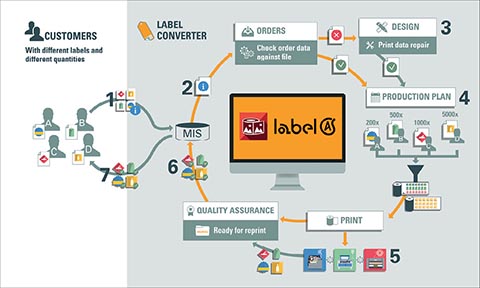

The integration of the two systems enables label printers to benefit from the core competence of both companies: Cerm software is a MIS (management information system) structuring business processes and organizing administrative workflows of label and commercial printers. With its Label Automation Suite OneVision takes care of a trouble-free print production process. The automation suite acts as middleware between the MIS and the RIP/DFE. Once the order for a label job has been received in Cerm's MIS, OneVision’s Label Automation Suite automatically prepares print data and finishing. Either of the two software systems actuates the printing press.

The Label Automation Suite starts with incoming orders and automates the entire label production process including data preparation, production planning, preparation of embellishment and finishing and machine actuation.

Even embellishment and finishing are being taken care of

With the automation suite label printers can benefit from an automated workflow and a comprehensive prepress package. In addition, special functions such as nesting, a cut line manager and a barcode generator as well as the creation of white and varnish masks enable automated preparation for finishing and embellishment.

An integrated production planning system enables collective printing of cross-customer jobs and significantly increases the throughput of label printers. The print-ready file then gets printed and, in the next step, sent and invoiced with the Cerm solution.

Joint OneVision and Cerm customers benefit from an automated end-to-end workflow from order receipt through print and finishing preparation to invoicing and delivery. As a result, label printers achieve significant time and cost savings and produce much more efficiently.

Find both companies exhibiting at the booth of hardware cooperation partner Screen Europe 9B30 at Labelexpo Europe in Brussels from 24 to 27 September 2019.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.