System Brunner INSTRUMENT FLIGHT® Expanded Gamut 7-C

Press release from the issuing company

Locarno, Switzerland – Instrument Flight is a process-related Color Management System that improves process mastery, automates printing in accordance with defined color-standards, boosts efficiency, and ensures the link to prepress, thus providing high cost savings. The heart of the system is innovative software for process assessment and color control – including gray balance technology that reflects many years of print process knowledge.

The software calculates color corrections in accordance with visual color perception including the color-relevant gray balances, halftones, tonality, L*a*b*, overprint/trapping, solid ink densities and more. Thanks to different weighting settings of the process parameters, the automatic color correction takes place at press start and during production more purposefully. Thus maintaining the defined print targets (e.g. ISO-PSO, G7, in-house standards) are not just logged afterwards when it is too late, but actively controlled during production.

Instrument Flight was the first color control system to achieve the new “Idealliance G7® Press Control System” certification. More and more printing companies in North America select Instrument Flight in packaging printing and high-quality commercial printing.

Until today, Instrument Flight continues to show its advantages over conventional density control, above all in CMYK printing. Spot colors are generally printed as individual solid areas and also controlled in printing as solids.

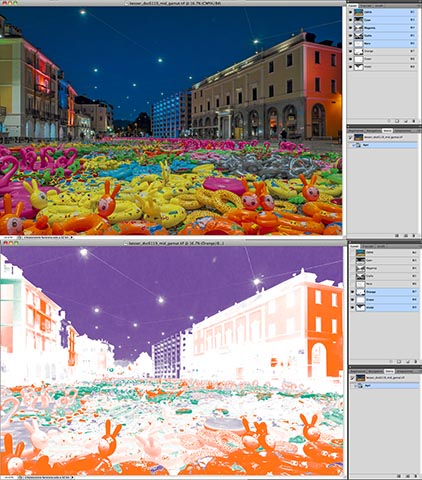

New Instrument Flight technology for color control with up to 7 process colors, CMYK + OGV (Orange, Green, Violet).

Especially in packaging printing, but also in high-quality commercial printing, hues outside the CMYK color space play an important role. To avoid using many different spot colors and reduce press make-ready time for color changes, the colors Orange, Green and Violet are added to the CMYK color space. As a result, these colors are not only printed as solids but also as halftones and combined with one another with different area coverages, also with CMYK.

These ideas are not new but up until now could only be applied in niche areas due to the elaborate, individual data processing. However, in recent time the separation technologies for 5/6/7-C printing available from different providers have been improved. Although there are still different pen questions (e.g. complexity in prepress, missing standards, screen angles, register with seven colors and fine negative type, etc.) the number of users is expected to grow considerably in future also due to cost pressure.

Higher demands on mastering the process with 7-C printing

Because prepress software providers are mainly concerned with the color separation, it is often forgotten that the process mastering and color control in 7-C printing is much more complex. It is no longer enough, besides CMYK with halftones, Gray Balance, Tonality etc., to keep the OGV colors in the solids constant. As already mentioned, these colors are screened and form new color combinations with overprinting and color balances, also affecting the four-color set and determine the visual appearance of the entire color reproduction. The printer now has to master the process with 7 printing inks in order to precisely achieve the prescribed color shades and keep the production run perfectly in color. This also applies to repeat jobs in different combinations of individual packaging.

For some time now, System Brunner has intensively examined the 7-C process for the expanded color space, carried out its own analyses and tests, and produced enhanced algorithms for color control with up to 7-C. One of the challenges here is the limited space for recording the parameters needed in control strips on sheetfed offset presses. Needed here, besides the correct measuring patches, are intelligent software algorithms that logically link up to 7 colors including halftones and overprint combination patches.

Different applications in printing demand individual objectives

To date there is no one standardized expanded color gamut for 7-C printing. The 7-C separations are individually produced on printing systems and materials in the course of test prints with process calibration. Depending on the job, all three colors O/G/V are not always used or in individual cases, one also uses the 7-C separations, simulating only the standard CMYK color gamut. As a result, the specifications vary widely and this must be considered when lodging the correct presets in the color control software.

System Brunner will successively supplement and integrate the new Instrument Flight ExG 7-C technology with its partners in sheetfed offset. Besides the new software solution, the product package also includes on-site training/advisory services with support for process calibration and implementation of the Presets/Standards in the software to match the inks and substrates. This is vital to ensure that the solution optimally fits in the entire customer workflow and the defined standards are automatically achieved with inline/online color control.

© 2025 WhatTheyThink. All Rights Reserved.