New Software Generation 18.2 from OneVision: Defy Cost Pressure with Prepress Workflow Automation

Press release from the issuing company

The launch of the autumn version 18.2 of the German software manufacturer convinces with highlights like the support of XPath, preconfigured assembly lines for an automated image workflow and the possibility to convert complex pages to images.

Regensburg – The cost pressure on print service providers is increasing. Prices for paper and raw materials continue to rise, while end customers do not accept higher prices. To achieve a sustainable profitability it all comes down to only one single measure: increase the degree of automation throughout print production – from prepress and print data preparation to printing and finishing. Significant support is being provided by OneVision's 18.2 generation of automation software solutions for prepress. By using innovative features, print service providers can simplify increasingly complex prepress workflows, design them flexibly, automate them, and thus increase profitability per print job.

Workspace – Simplify workflows with "job phases", increase dynamics with XPath support

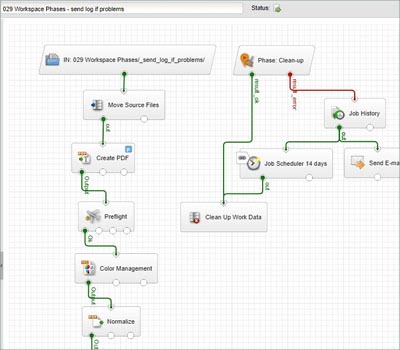

Workflows are becoming more and more complex as a result of a wide variety of customer requirements. In order to maintain a clear overview of the workflow, assembly lines can now be structured with the help of phases. The display of the assembly lines is significantly simplified. Manual "clearance work" is prevented by the automatic removal of exported files. All ‘Workspace Pro’ customers can look forward to XPath support. Users can now dynamically overwrite the settings of each module based on attributes at runtime and thus design their workflow flexibly according to the individual requirements.

Structured workflow through phases

Asura – Speed up the RIP process through conversion of complex pages, automatic tiling

Complex pages include large amounts of graphics and/or images and can therefore only be processed very slowly, which again slows down the RIP process. With the new feature "Convert complex pages into images" the prepress software Asura now converts these pages into an image and thus speeds up further processing steps significantly. Further developments have also been made in the areas of nesting, tiling & paneling and in the barcode module: Labels cut with a conventional cutting machine can now be nested. With the "Tile pages" module, page formats larger than the maximum print format can be automatically divided into printable individual pages. Barcodes can now be placed more flexibly using extended options.

Amendo – preconfigured best practice workflows for an automatic image workflow

The image optimization software Amendo now offers preconfigured best practice workflows for an automatic image workflow. Major magazine publishers with diverse titles such as Fashion, Food, Magazine, Real Life, Technology and Yellow Press can optimize their images according to defined color worlds. These have already been successfully tested with leading magazine publishers. Amendo processes images in the assembly lines, applying the optimization steps necessary to achieve optimal effects for each magazine style (e.g. authentic, colorful, high-quality, brilliant, etc.). For those who only want to process images without optimizing them, Amendo Processor comes in handy. It processes all files that do not require any optimization directly, accelerating the entire workflow.

Of course, these further software improvements are integrated to the Automation Suites for wide format, book and label printing.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.