Sealtronic Nozzle Sealing System Prevents Ink in Industrial CIJ Printers from Drying

Press release from the issuing company

Tuttlingen – To ensure that CIJ printers can get back to work immediately after the summer break, Paul Leibinger GmbH & Co. KG developed Sealtronic – a mechanical nozzle sealing system that is unique on the market. It protects the ink in industrial printers from drying out and enables an immediate start without the need for cleaning, even after several weeks of production break.

Printers that use so-called Continuous Inkjet (CIJ) technology are used in industry for product marking and coding. In the printhead, electrically charged drops of ink shoot through a nozzle into a collection tube. During their flight, a high-voltage field deflects individual drops so that they end up as pixels on the product – for example on food packaging or an electric cable. For example, best before dates, batch numbers and 2D codes are created pixel by pixel.

CIJ technology is a flexible marking technique that can lead to problems after production breaks. Some manufacturers call for the time-consuming emptying of the printer following longer shutdowns. Others rely on a closure system that users manually put on the nozzle and catcher tube. “We know from customers that the ink in most CIJ printers regularly dries up after the summer break in spite of closure systems,” explains Christina Leibinger, Managing Proprietor of Leibinger. “This leads to time-consuming cleaning that delays the start of production and often results in significant start-up problems.”

Nozzle sealing system keeps ink fresh during the summer break

“Some customers even regularly have employees go into the factory to start up the CIP printers during the summer break to avoid drying,” says Leibinger. “That’s why they are so impressed with our Sealtronic nozzle sealing system, which automatically keeps ink fresh in all Leibinger printers during the summer break.” When the user switches off the printer, Sealtronic automatically closes the nozzle and catcher tube. The catcher tube is driven by a spindle drive onto the nozzle and both modules are therefore hermetically sealed. The ink jet only turns off when the system is sealed. Therefore, air doesn’t have a chance of entering the closed ink circuit, unlike with some competitive closure systems that use mechanical flaps or rubber stoppers to try to prevent the system from drying out.

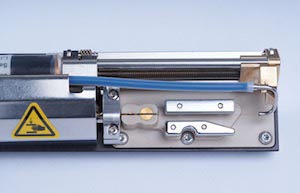

Open print head: Before the ultra-thin ink jet switches off, Sealtronic automatically closes the nozzle and the collector tube. The automatic nozzle closure system keeps the ink fresh

Moreover, in the stand-by mode, the printer rolls the ink through the hydraulic system once a day, preventing deposits from forming in the case of pigmented inks. This automatic ink ‘refresh’ is possible only since the ink circuit is not barricaded by an insert. It also ensures the safety of a closed system. Power consumption is negligible. Leibinger printers have a power consumption of about three watts in stand-by mode – as little as a DVD player in stand-by mode. “If the user switches the printer on again after the summer break, it is immediately ready for use – without the need for time-consuming cleaning, which unnecessarily delays the start of production.”

ABB Schweiz AG: Three hours less cleaning required

The benefits of Leibinger’s unique Sealtronic feature not only come into play during and after the summer break, but also in everyday production. Jürgen Eberle, Production Supervisor at ABB Schweiz AG Installation Products (EPIP), is impressed. “In our search of new inkjet systems, we came across Leibinger. And I have to say, it has been our best move to date,” explains Eberle. “We used to have to spend two to three hours a day cleaning. This has been entirely eliminated.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.