Next Cortina Comes On Stream at ICP-Roto on La Réunion

Press release from the issuing company

- Waterless in the Indian Ocean

- Production flexibility through variable web widths

- Process optimisation with waterless technology

- Modern press hall for new Cortina

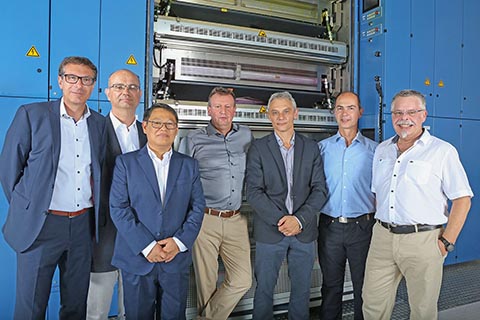

Happy faces at the official ceremony (l-r): Bernd Hillebrand, sales manager KBA-Digital & Web; Pierre Pommier, KBA-France; Alfred Chane-Pane, managing director ICP-Roto industrie graphique; Georg Zitterbart, printing instructor KBA-Digital & Web; Philippe Van Damme, technical director ICP-Roto industrie graphique; Gerold Dornbusch, commissioning engineer KBA-Digital & Web; Peter Benz, project manager KBA-Digital & Web

ICP-Roto industrie graphique, a highly respected commercial and newspaper printing house on the island of La Réunion, celebrated its new Cortina from Koenig & Bauer with an official ceremony. Some 300 guests attended the press’ official start-up. “The new Cortina is the centrepiece of our printing house. Our whole team is incredibly proud of the new press. Once again, Koenig & Bauer and our team worked together perfectly on its installation and commissioning,” says managing director and owner Alfred Chane-Pane. The installation of the press line also confirms the importance the company’s management attaches to ecological concerns on an island where the tourism industry dominates. Alfred Chane-Pane: “Environmental protection is a matter dear to our hearts. Given that it eliminates the need for dampening units and all the associated additives, Cortina technology is ideal for the eco-friendly production of many very sophisticated products.” Installed in a new modern press hall, the Cortina has already taken over a large proportion of the company’s overall production.

High degree of automation for simple handling

The Cortina comprises an automatic reelstand, an ultra-compact printing tower, an efficient hot-air dryer system, a flexible superstructure and two semi-commercial jaw folders. This impressive press line incorporates numerous automation modules such as the Patras A reel-loading system, automatic plate and circumference change, CleanTronic washing systems and RollerTronic roller locks, as well as colour and cut-off register controls. “The Cortina is definitely much easier to operate than conventional offset presses,” says technical director Philippe Van Damme.

Process optimisation with waterless technology

The Cortina waterless printing technology permits not only sharper print details and finer screen rulings, but also hybrid production options and seamless switchovers between heatset and coldset production. Full utilisation of these strengths have already been factored in for the future, not least through preparations for expansion with a further coldset web. Through the elimination of dampening units and ink keys, Cortina technology is predestined for applications with variable web widths. This production flexibility facilitates the printing of a broad diversity of job types, such as magazines, brochures and supplements in a standard magazine format, as well as flyers in attractive special formats, alongside traditional tabloid-format newspapers and newspaper-like products. Thanks to the two folders, high-capacity 4-up production is an interesting possibility, and even 8-up production is possible with special formats.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.