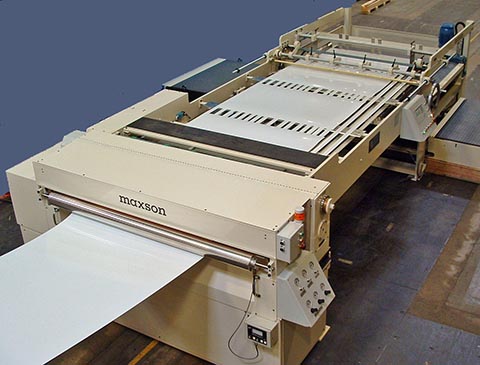

Maxson Sheeter Meets the Demands of Coated Film Plastics Market

Press release from the issuing company

Manufacturers of coated film plastic can now sheet the product at higher speeds than conventional drop shear equipment, while insuring the square, accurate dimensions required by the Printing Industry using a sheeter designed by MAXSON AUTOMATIC MACHINERY COMPANY (Westerly, RI USA). A continuous operating system is provided, allowing sheeted material to be accumulated until completed pile is removed.

In this sheeter design, the cutting section includes knives mounted in an upper and lower rotating cylinders. The cylinders accelerate and decelerate during each revolution such that the peripheral speed of the blades and the speed of the web are equal at the cutting point maintaining sheet length accuracy and squareness. This cutting action eliminates the skive along the leading and trailing edge on thicknesses up to 0.060” (1.5 mm) thick, without producing slivers. Using an exclusive clash arrangement, the Operator can safely adjust the cross cutting blades while the cutter is running.

The MAXSON SDFK Sheeter can handle cut lengths from 11 inches – 2,000 inches (279 – 51,000 mm) at speeds up to 300 fpm (90 mpm). Equipped with a reject gate, out of specification sheets or sample cuts used for quality assurance inspections can be diverted from the sheet flow to the stacker to a customer supplied bin.

When outfitted with the continuous run design, the inline configuration of the sheeter allows for non stop operation while a full pallet of sheeted material is offloaded and an empty skid is raised into position.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.