At FESPA, Esko Leads the Way in Automation for Sign, Display & Digital Corrugated Markets

Press release from the issuing company

Ghent, Belgium – The analog-to-digital transformation is sweeping through the sign, display and corrugated markets as sign providers and corrugated converters look beyond their production equipment to find an automated end-to-end workflow that ensures faster time to market, fewer errors and improved profitability. Waste can be created everywhere; via complex manual steps, equipment idle time, incorrect material handling or lack of workflow control. Many providers are seeking to eliminate waste and streamline the process from a design request coming in to shipping out a product. At FESPA 2018, they will find the path to this improved productivity and profitability at Esko Stands 3.2-C48 and 5.2-D30 during the 15 to 18 May event in Berlin.

Geert De Proost, Esko’s Director Solutions Marketing, said, “Our focus is on supporting the sign and display and corrugated sectors with integrated hardware and software solutions that address the requirements of a company’s business strategy. Our solutions will dramatically boost production capacity without the need to invest in additional headcount. They will also eliminate human error at every step by standardizing processes. We are especially excited to present Automation Engine QuickStart for Sign and WebCenter QuickStart for Corrugated converters. Esko’s QuickStart solutions, offer companies out-of-the-box, proven and expert workflows for sign and wide format production, as well as the digital workflows required to speed up the time to market of corrugated products. The implemention of the QuickStart solutions, only takes five days. And once they start down the digital path, it is easy for them to continue to add features and functionality to continue improving productivity and profitability.”

At the show

For sign and display graphics businesses, the analog-to-digital transformation is well underway. But while today’s wide format printers are more efficient and deliver higher throughput, there are still often bottlenecks in other parts of the design-request-to-shipping workflow. To help companies overcome these challenges and shorten time to market while improving productivity, Esko offers Automation Engine QuickStart for Sign – a turnkey workflow solution that automates prepress, enabling companies to handle more jobs faster. On display in stand C48 in Hall 3.2-, this easy-to-implement solution will have companies up and running with improved Overall Equipment Effectiveness (OEE) in five days , to immediately begin benefiting from the investment. It comes preloaded with proven workflows for sign and large format production, giving companies the possibility to eliminate repetitive tasks . It also includes a direct link to Kongsberg cutting tables, significantly increasing workflow automation with less waste in the most expensive step of the process – finishing – since setups are automatically loaded into the Kongsberg workflow. It automates a wide range of tasks from product creation and preflight to approvals and production. Its customizable dashboard and reports ensure everyone involved in the process has immediate access to all information required to speed work through the plant and make fact-based business decisions for continuous operational improvement.

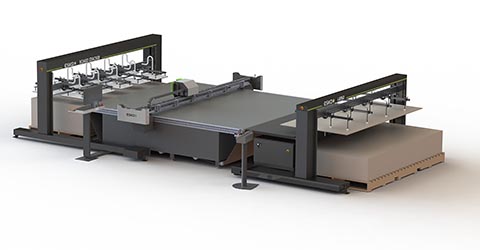

De Proost adds, “And visitors to our stand will be amazed to learn they receive all of these benefits without the need to add headcount. In fact, it enables companies to reassign employees to more productive tasks while the QuickStart solutions take care of the non-productive repetitive tasks that are a waste of employee time. Operators can use Device Manager to monitor job status, and to manage and prioritize the queues of all connected devices, from the convenience of their offices without the need to run around machine to machine.” In finishing, Kongsberg Automate aids increased productivity; it offers a broad array of impressive innovations that boost the performance of digital finishing operations to industrial levels. This includes the ability to add robotics for loading new materials and offloading finished materials for increased productivity and reduced operator interaction. At FESPA, a Kongsberg C64 cutting table equipped with a Feeder and Stacker will be on display.

The Kongsberg C64 is a multifunctional, super wide digital cutting table for signage and display applications. Russell Weller, Product Manager, said, “The Kongsberg C combined with the Feeder and Stacker delivers the ultimate 24/7 performance and is designed to keep up with the faster, wider digital printers of today. With stack height at 915 mm/36 in and quick automatic load cycles it is the optimal solution for short run production on all typical packaging and display materials.It’s an investment in future-proofing sign and display graphics businesses.”

Also on display in the Esko stand will be a Kongsberg X20 entry-level cutting table together with a wide range of specialty tools. Offering the ultimate in versatility, these tools deliver speed, power and flexibility to handle a wide variety of materials, such as corrugated, folding carton, solid board, foam, coating blankets, wood and a long list of plastics.

Esko Corrugated Solutions

Esko will also be present on Stand D30 Hall 5.2, where the focus will be on solutions for the Digital Corrugated sector. For the first time, Esko will demonstrate its WebCenter QuickStart for Corrugated, a packaging management solution for corrugated converters designed to handle design requests in minutes. Esko will also demonstrate the key elements of its ArtiosCAD solution for structural design, Studio for 3D projects, and i-cut Suite for optimization of prepress production. “The analog-to-digital transformation in corrugated is just beginning,” De Proost stated. “Esko has applied learnings from other market segments to speed this transformation for corrugators of all sizes. We believe visitors to our stand will be amazed at how quickly an investment in packaging design solution for corrugated will pay for itself in better customer communications, reduced wasted, improved productivity and OEE, and faster time to market.”

De Proost concludes, “We are looking forward to learning about the business issues visitors to our stand at FESPA 2018 are facing, and demonstrating how our tools have been developed to offer maximum OEE on the shop floor, as well as how they help reduce waste. The difference with Esko tools is in our analysis of the customer’s needs; we look first at the company’s strategy upstream and downstream and focus on eliminating pressure points, bottlenecks and errors. Based on many years’ experience, Esko continues to lead the way in workflow automation and simplification.”

For further information please visit www.esko.com.

Kongsberg C64 with Feeder Stacker.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.