TOPPAN to Launch Indian Production of BOPP-based GL-SP Barrier Film for Sustainable Packaging

Press release from the issuing company

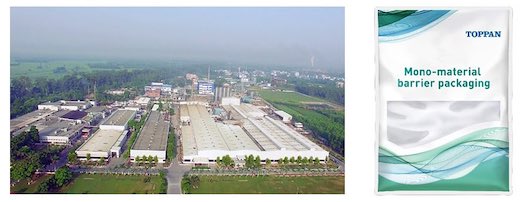

(Left) TSF’s plant (Right) llustration of mono-material barrier packaging using GL-SP

Achieving high level of competitiveness with end-to-end production of both base film and barrier film and catering to mono-material needs by applying transparent barrier to BOPP substrate

Tokyo –TOPPAN Inc. (TOPPAN), a TOPPAN Group company and wholly owned subsidiary of TOPPAN Holdings Inc., and India-based TOPPAN Speciality Films Private Limited (TSF) have developed GL-SP, a barrier film that uses biaxially oriented polypropylene (BOPP) as the substrate, and will soon launch production and sales.

GL-SP is a new addition to the range of products for sustainable packaging in the TOPPAN Group’s GL BARRIER1 series of transparent vapor-deposited barrier films, which enjoy a leading share of the global market. From April this year, TOPPAN and TSF will launch sales of GL-SP for packaging of dry contents, with a focus on markets in the Americas, Europe, India, and the ASEAN region.

GL-SP is the first product from the TOPPAN Group for which stages from substrate BOPP film manufacture (resin formulation and film-forming) to barrier film (GL FILM) production will be carried out in an end-to-end process at the same location. This is expected to enable stable quality control and reductions in product development timelines, lead times, and costs.

The base film used for GL-SP is BOPP, which is seeing increasing demand for use in sustainable packaging. GL-SP can cater to the needs of a wide range of markets due to properties that include high oxygen barrier and water vapor barrier (damp-proofing) performance—making it ideal for the packaging of dry contents—as well as transparency that allows contents to be seen and a thin form that contributes to reducing plastic consumption.

Background

With attention focused on decarbonization and addressing the problem of plastic waste, demand for more eco-friendly packaging continues to increase. Recycling initiatives premised on mono-material packaging are accelerating around the world, with many global companies announcing targets for the circulation of plastic resources associated with containers and packaging and launching various efforts to achieve them.

TSF has now addressed these challenges by developing GL-SP with BOPP as the substrate. This will facilitate a shift to mono-material structures for product packaging for dry contents.

Features of GL-SP

Suitability for mono-material packaging

GL-SP uses a BOPP substrate to enable mono-material packaging that caters to increasing demand for improved recyclability.

Outstanding barrier performance

GL-SP demonstrates barrier performance2 equivalent to that of general vapor-deposited PET (water vapor barrier: 0.5g/m2; oxygen barrier: 0.5cc/m2) and is ideal for the packaging of dry contents.?

High level of transparency

While maintaining barrier performance, the high level of transparency makes contents visible, enabling differentiation in packaging design and enhancing appeal for the consumer through enhanced visibility.

Future

The TOPPAN Group will launch sales and sample shipments in April this year with a focus on markets in India, the ASEAN region, and North America and Europe, where there is a high level of interest in sustainable packaging.

1. GL BARRIER

GL BARRIER is the TOPPAN Group’s proprietary brand of barrier products centered on GL FILM, a transparent film that delivers world-class barrier performance. GL FILM’s stable performance is enabled by a multi-layer structure combining a unique coating layer with a high-quality vapor-deposited layer. In recognition of their numerous outstanding features, GL BARRIER products are used in a wide variety of fields, including the food, medical/pharmaceutical, and industrial materials sectors.

https://www.toppan.com/en/living-industry/packaging/products/barrier_film/

2. Barrier performance measurement conditions

Water vapor barrier (38? 90%) Unit: g/m2?day

Oxygen barrier (23? 0%) Unit: cc/m2?day?atm

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Only verified members can comment.