Uncanny Results: UW-Stout Students Win International Challenge to Imagine New Packaging for Pringles

Press release from the issuing company

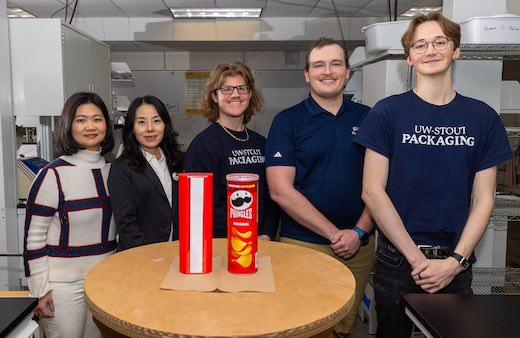

From left, professors Min DeGruson and Kate Liu and students Zach Hoffmire, Lukas David and Ethan Myers.

Their oblong-shaped tube would prevent broken chips, be recyclable and provide easier access for snacking

Menomonie, Wis. — Imagine creating a new package for a product that has been on store shelves around the world for more than 50 years. How would you make the package better while ensuring consumers still recognized their favorite brand?

That’s the challenge a team of University of Wisconsin-Stout students took on in a competition sponsored by Kellanova, a division of Kellogg’s, and the Packaging Association of Canada. The goal: Redesign the iconic, upright can that holds one of Kellogg’s beloved products, Pringles chips, to improve the Pringles snacking experience.

An innovative design by Lukas David, Ethan Myers and Zach Hoffmire popped to the top, taking first place in February against an invitation-only field of eight other university teams from the U.S., Canada, Germany and the United Kingdom.

What made UW-Stout’s champion entry stand tall? The students:

Designed an oblong — or in industry terms racetrack-shaped — tube to reflect the shape of the chip, instead of the existing round tube. The new shape would stabilize the product and prevent breakage.

Made it of recyclable plastic. The traditional can, cardboard with a foil lining and a metal bottom, isn’t recyclable.

Added a narrow, peel and reseal tab on the curved, front side of the can for better access.

Redesigned the lid into a tool that could be used with the side tab to push remaining chips to the top, rather than having to tip the can upside down or reach in to get them out.

In the end, it still looked like a Pringles can but was more user and environmentally friendly.

The team won nearly $1,900 and the satisfaction of being recognized by leading industry professionals for their expertise.

Coincidentally, in January, well after competition entries were submitted last summer, Pringles began rolling out a new recyclable can — still round — made mostly from recycled paper, including the base. It also had a recyclable plastic lid, part of an expanded company initiative to make eco-friendly products.

Packaging majors Myers, of Pleasant Prairie, and David, of Johnson Creek, worked on the prototyping. They said the traditional package was overdue for a makeover.

“Pringles packaging is one of those things that I’ve always found myself frustrated by but had never thought too far into it,” Myers said. “To actually be presented with the prompt, it felt very familiar.”

David agreed: “It is a very difficult package to use, and there are a lot of broken chips in the packaging constantly.”

A video demonstrating and explaining features of the design was created by Hoffmire, of Kenosha, a video production major. It was part of the competition submission package.

Research and development

The final design was the product of an exhaustive research process outside of classes in summer 2023. Myers and David brainstormed nearly 100 ideas, working through them one by one using various criteria and a design rating system.

The final choice was a nine-layer, food-safe structure, easily moldable, with precise amounts of plastic in various locations. They created a 3D model, 3D-printed the final design in a lab and filled it with Pringles for user testing. Everything worked.

Entries also had to address inclusivity and accessibility for users. Myers and David sought feedback from senior citizens and people with disabilities, including conducting a survey at DisFest in Chicago. The tool that can be used to get the chips out of the can helps address accessibility and general usability.

“Inclusive design is starting to become more prevalent in packaging because the population is aging. Packaging is becoming harder to open. User-friendly designs will be necessary,” David said.

Their advisers were Kate Liu, assistant professor, and Min DeGruson, associate professor and director of the packaging program. They also received support from UW-Stout plastics engineering professors.

“They did tons of research and proved ‘the why’ and intent behind their design while also creating a fantastic prototype that kept the current brand feel but was a true innovation as far as all of the design criteria it addressed," Liu said.

UW-Stout packaging students have won multiple competitions over the last couple of years, including the Pack Expo Amazing Race collegiate competition and Flexible Packaging Association Student Design Challenge.

In 2023, Myers, David and Hoffmire won the Paperboard Packaging Alliance student competition and the Institute of Packaging Professionals’ 48HR REPACK student design competition.

“This one was special as it was an invite only, international competition. It was the best of the best competing against each other,” Myers said of the PAC Pringles win.

Teams from Toronto Metropolitan University and Durham College, both in Canada, took second and third place, respectively.

The packaging program will be back in the spotlight in April. The student Stout Packaging Association will host Packaging Jamboree 2024, or Pack Jam, from Sunday, April 7, to Tuesday, April 9. Students from packaging universities and colleges in the U.S. and Canada will connect with industry professionals and alumni to showcase the impact that packaging has on the world.

Hoffmire will graduate on May 4. Myers and David will graduate in December.

The students haven’t heard whether Kellogg’s might consider changes to Pringles packaging based on their design.

UW-Stout is Wisconsin’s Polytechnic University, with a focus on applied learning, collaboration with business and industry, and career outcomes.

Learn more via the FOCUS2030 strategic plan.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.