VOTES ARE IN: Inland Press’s new RMGT 970 Long Perfector Boosts Productivity

Press release from the issuing company

CLEVELAND, OH – Graphco, a leading graphic-arts equipment distributor in the United States, has installed an 8-UP+ RMGT 970PF-8+LED eight-color (four-over-four) perfecting press at Inland Press. A subsidiary of publicly held Detroit Legal News, the 129-year-old general commercial print firm counts automotive and healthcare companies among its clients. In addition, election-related printing represents a sizable chunk of the company’s $10 million in annual sales.

Since campaigning has already begun for 2024 election season, the new RMGT press was quickly installed after its exhibition at the PRINTING United Expo in Atlanta. “There’s an early presidential primary in Michigan [on February 27th],” explains CEO Brad Thompson, “so we’ve already kicked into high gear.” The pre-ballot action will heat up this summer, he adds, “heading right up to election day in November.” Thompson reports that, in 2022, Inland Press reproduced some 100 million pieces of election materials intended to inform and persuade U.S. voters. The firm’s 45 full-time employees workload peaked at two 12-hour shifts, seven days per week.

“We were literally running around the clock, with a lot of overtime,” recalls the chief, who has seen myriad changes during his four decades of working in the printing industry. He also is a fifth-generation member of the Thompson family-run operation at Inland Press. “I guess you could say there’s ‘ink in my blood,’” says Brad, acknowledging his family’s proud legacy.

Additional capacity at the plant was necessary because, this year, Inland expects its “political” print runs to jump to between 140 million and 150 million pieces. With that much more ink on paper, job turn-around times “are measured in hours, not days,” he notes. Yet, despite the estimated 40% to 50% increase in volume, Thompson says crew members will achieve their production goals while working shorter (10-hour) shifts than they did two years ago -- and minimal weekends. Meanwhile, Inland plans to incur much lower overtime charges.

How can Inland print 45% more volume in 25% to 30% fewer man hours?

Doing more with less

“That’s the beauty of the long perfector” and its ability to print double-sided on each sheet, explains Chris Manley, president of Graphco. “Running full-color 8-UP+ printed sheets on both sides at 15,000 SPH in only one pass through the press is a huge production advantage,” he notes. “So, from a finished piece production standpoint we are producing at the equivalent of 30,000 SPH on the single sided presses Inland ran last election season.”

But the beauty of the 970 platform goes well beyond the excellent production improvement it provides. From a return-on-investment (ROI) perspective, the far better price point should be considered as well. While the RMGT 970PF-8+LED processes the most commonly produced U.S. sheet size of 25” x 38”, it can cost over a $1 million less than a comparable 40” sheetfed-offset printing press. In an apples-to-apples shopping comparison, Thompson says one competing manufacturer’s price was almost double, for a press that prints a sheet 2” wider. Manley adds that an annual debt-service coverage ratio (DSCR) that is $180,000 to $200,000 less can be much less of a strain on RMGT 970 user’s bottom lines.

In addition, the press’s faster makeready times are aiding Inland’s quick turns and overall operational efficiency. While it’s still too early for hard-data metrics (the new press only began operating in November 2023), Thompson reports that operators are getting up to color and pulling good sheets much quicker, which results in wasting less paper. “A part of that [enhanced speed] is RMGT’s fully automated plate-changing system,” he points out.

From a total cost of ownership (TCO) standpoint, the smaller footprint’s savings on other consumables add up, too. For example, “plates cost 15% less for the 38-inch press,” Manley points out. Plus, with no second operator needed to run the 970, conserving labor cost is an added bonus that passed muster in Inland Press’s unionized shop.

Thompson notes: “Needing only a single operator per shift gives us more flexibility to move around skilled personnel. We have had no layoffs,” he stresses. In fact, Inland Press is hiring.

Assuring zero defects

Inland’s new high-tech press, manufactured by RYOBI Mitsubishi Graphic Technology, features full ASAP (Automatic SMART Assist Program) automation, including state-of-the-art PQS-D-I-R inspection. The addition of this system is important to several customers, Thompson explains, especially those in the automotive and healthcare vertical markets. PQS-D-I-R cameras catch imperfections, such as so-called hickeys, “and do accurate color to within a couple of Delta E,” he notes.

The system employs solid-state (CCD) cameras to inspect every sheet for quality, while instantly adjusting color and registration. It tags any sheet in the press delivery that fails the quality inspection so it can be diverted out of the finishing process to provide zero-defect output.

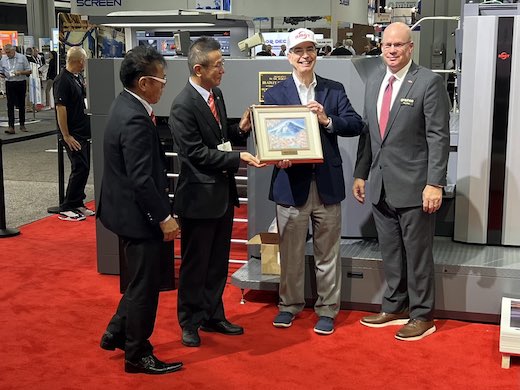

“During Phase 2 of the press installation in January, the full ASAP technology package will be added and training will be conducted,” Thompson says. This press configuration marks a first-of-its-kind installation in the United States, which is why the manufacturer “showed off” the model on the floor of the PRINTING United Expo this past October. After the tradeshow in Atlanta, components were packed up and shipped for permanent set up at Inland’s 65,000-square-foot facility, which is situated in Detroit’s historic Corktown neighborhood.

‘Green’ is Good for the Environment & for Business

Environmental sustainability is the proverbial icing on the cake for Thompson and his team at Inland Press. Along with many of their customers, the company is striving to become more ecologically sound and reduce its carbon footprint. “This is the first LED press we’ve had,” he explains, calling the technology a game-changer. “LED curing eliminates VOCs from the pressroom; and the printed sheets are dry when they hit the delivery.” Bindery employees are “ecstatic,” he adds, because instantaneous curing means there is no need for spray powder, which can build up on rollers and effect productivity and quality.

“Inland’s earnings-per-share numbers for 2024 are extremely aggressive,” Thompson concludes. “A lot of those financial projections are based on our confidence in this new press technology from RMGT and how it will perform. We are excited about the future!” Chris Manley adds, “The new partnership between Inland Press and Graphco makes us extremely proud, and Brad’s Team have been awesome to work with on this new technology implementation. To be part of Inland’s 130thyear in business is a great honor, and we can’t wait to see how their new RMGT press will impact their next 130 years.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.