Baldwin Leads the Way in Achieving Print Perfection at the FTA Fall Technical Conference

Press release from the issuing company

Inspection and LED UV technologies deliver superior accuracy, quality, efficiency and sustainability

ST. LOUIS, Missouri — Baldwin Technology Company Inc. will highlight the level of perfection achievable with its inspection and LED technologies for narrow and wide web print at the FTA Fall Technical Conference with Infoflex. Taking place in Louisville, KY, from October 9-11, the fall event from Infoflex is a more intimate opportunity to speak with technical experts from companies spanning the entire package printing production workflow.

During the conference, in booth #306, Baldwin will highlight its new printing inspection software, Guardian PQV 4.0 for labels and narrow web. The system provides complete print quality, bar code and variable data verification on any press or post-print machine, as well as advanced capabilities for the most demanding applications. With a few simple clicks PVQ 4.0 can set up a repeatable process that lowers the technical barrier of entry for employees. The system automates the printing job process, taking the stress out of managing the previously complex tasks. The new and improved scanning technology can detect errors and faults with micrometer precision and give a detailed report for correcting the mistakes.

Additional solutions on display include Defender inspection, offline proofing, web viewing, Color Measurement with DeltaCam, and LED UV technology.

Powerful yet simple to use, the Defender platform speeds wide web production while ensuring that no defective material gets into customers’ hands — saving time and money.

The Guardian OLP Offline Proofing & Inspection system verifies the files used for production — or the beginning-of-run press samples — match the customer-approved master file 100%, ensuring accuracy at the start of your print run.

Baldwin’s web viewing systems help operators catch defects and register errors before they become visible to the human eye and Color Measurement with DeltaCam delivers affordable, accurate inline spectral measurement on film, paper or board.

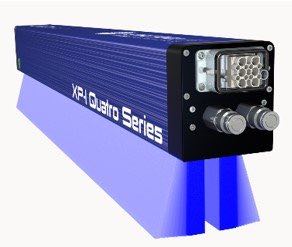

Furthermore, Baldwin’s AMS Spectral UV-brand LED UV technology offers the highest curing intensities available for printing. Benefits of LED UV include a 65% reduction in energy consumption, reduced costs related to parts and service, increased productivity and greater effeciency stemming from the lack of waiting for lamps to warm up or cool down.

Common to all the technologies is that they increase productivity, reduce waste, improve working conditions and provide full control of producing flawless products. With easy automation and compatible software, Baldwin’s technologies are seamlessly integrated with one another.

“With the continued growth in the packaging market, Baldwin Technology is perfectly placed to help customers achieve their goals around increased quality, productivity, sustainability and safety,” said Craig Black, Baldwin’s Vice President of Sales for the Americas. “Whether it be our online or offline inspection systems, color measurement or the latest technology in LED UV curing–to name just a few of our capabilities–all our solutions are made in the United States and backed up by the best service and support in the business.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.